Expandables and the monodiameter well: Status report

Oil Country Tubular GoodsExpandables and the dream of the monodiameter well: a status reportNow five years old, this rapidly evolving technology is pointed at the ultimate application of a single-diameter well. So what's taking so long? Here's why it's not that easy.Perry A. Fischer, Editor A knowledgeable speaker quoted some unnamed study that purported new technology took 26 years after commercial introduction to get into widespread oilfield use. That has certainly not been the case with expandable technology. As the pages in this year's and last year's World Oil reports show, there are now dozens of new uses in drilling and completion, and hundreds of jobs completed. But of all the applications to date, none are as far-reaching and game-changing as the monodiameter well. A review of the benefits, the progress achieved and problems to be overcome follows. KEY DRIVERS Most often, the key driver for change is cost. Monodiameter wells are no different in that respect, but the magnitude of the savings could be dramatic. They also extend to environmental benefits as well. Of course, savings center on the direct reduction in diameter, since every inch of wellbore larger than what is needed at the producing zone to accommodate production is wasted (see Fig. 8 pg. 61). This has been the driver behind Reduced Casing Clearance Programs (RCCP) and slimhole completions. From this simple reduction in ID, the benefits multiply, from fewer emissions due to reduced motor use, to use of earlier-generation, smaller rigs. It should allow a reduction in field size for economic development, as well as drilling deeper wells at less cost. A recent SPE paper put the savings at 59% for cuttings disposal, 38% for casing weight, cement volume reduction of 42%, and 44% less drilling fluid volume. An analysis of a 29,000-ft well drilled in 5,000-ft deep water showed savings of $12 to $31 million.1

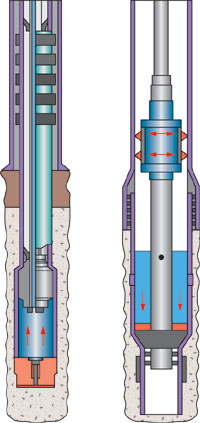

CHALLENGES Expandable tubulars must meet rigorous standards beyond those of ordinary pipe. Besides metallurgy, drift ID must be tightly controlled. Also, galling and defects, both internal and external, can act as seed spots for ruptures when the metal is expanded.1 These problems have been largely overcome, in part, through careful handling similar to chrome 13 pipe. However, research continues into stronger, more robust and cheaper expandable pipe, as well as improvements in the expansion cone. For a true monobore, conceptually, what has to occur is a bell-shaped (or flared) upper pipe into which a lower, subsequent pipe is expanded, Fig. 1. In practice, both pipes are expanded simultaneously, and the upper pipe could be the bottom-most piece of conventional pipe from the surface string or a subsequent string. The problem is, establishing the bell shape means either expanding conventional pipe or expanding a previously expanded pipe even farther. Three interrelated problems immediately come to mind: 1) there is a limit as to how far pipe can be expanded; 2) the borehole must be enlarged at least 1 – 1.5 inches beyond the OD of the bell to allow room for cement, which immediately calls into question the type of bit capable of the required hole-enlarging; and 3) there must be a way to hang/ seal subsequent sections. Thus far, the practical limit of plastic deformation without risking pipe fracture is an expansion ratio of 30%. The overlap area, or bell, is the deciding factor of expansion rates due to the higher ratio required. Expanding 9-5/8 x 11-3/4 -in. pipe results in a 10.4-in. ID. This implies a basic expansion rate of 17%. If this is to be inside a bell, the bell must expand 24%, which is well within the feasible expansion ratio. This makes 9-5/8 x 11-3/4 in. pipe a practical monodiameter size. To apply the expansion process to 5-1/2 x 7-in. pipe to 6.1-in. ID gives a basic expansion of 25%, while the corresponding bell must expand 42%. Thus, because the bell expansion exceeds the practical expansion limit, 5-1/2 x 7-in. pipe is not yet suitable for monodiameter applications. Finally, if we consider expanding 7-5/8 x 9-5/8 -in. pipe to 8-in. ID, the result is an expansion of 19%, while the bell expands 29%. Therefore, 9-5/8 -in. pipe is the smallest usable size for monodiameters, at least with respect to material limitations. Smaller sizes are likely to become viable as the technology envelop is pushed. The second aspect of applying monodiameter drilling liners is the size of the borehole for the expanded bell. A 9-5/8 x 11-3/4 -in. monodiameter drilling liner creates a 10.4 in.-ID and a bell OD of 11.8 in. Sufficient cement clearance of 1.5 in. requires a hole of 13.4 in. This means a bit would have to increase from 10.4 in. to 13.4 in. – a 127% increase, which is just within present hole-opener technology, such as bi-centered bits and underreamers commonly used in RCCP. Similarly, the 5-1/2 -in. monodiameter drilling liner with 6.1-in. ID has a bell OD of 7.5 in. Using a cement clearance of just 1.0 in. requires a hole size of 8.5 in. and a bit expansion of 142%, which is outside of today's bit technology.2 A 7-5/8 -in. x 9-5/8 -in. monodiameter drilling liner and a cement clearance of 1.5 in. requires a hole of 11.1 in., which requires an increase in hole size of 134%. This puts 7-5/8 -in. monodiameter drilling liner on the cusp of current hole-enlarging technology, but it could be possible with minor enhancements. Lastly, hanging consecutive monodiameter liners requires some sort of hanging/ sealing. The method used has been a short joint of pipe periodically wrapped in elastomer, Fig. 1. Expanding the pipe activates the elastomer, forcing it into the annulus and sealing the connection. SOUTH TEXAS EXPERIMENT A collaborative effort between Shell Exploration & Production Co., Shell International Exploration & Production Inc. and Enventure Global Technology resulted in a successful experiment of two short expansion sections in a well in Starr County, South Texas, in mid-2002. At present, two expansions remain necessary. The first (bottom up) expands and seats the new section within the previous string. The second expansion (top down) creates the final monodiameter ID and the flared bell, Fig. 1. The first cone was 9.9 in. and was launched from a pre-formed cone launcher, housed in the base of the expandable joint. The second cone was a top-down expansion of 10.4 in. The end of conventional casing was a 11-3/4 -in., 60-lb, P-110 casing. Another 300 ft of 10-5/8 -in. hole was drilled, then underreamed to 12-1/4 in. The 9-5/8 -in. expandable liner was run and expanded to 9.9-in. ID hydraulically by pumping mud down the drill pipe, which forces the cone upward. The liner lap was hung and sealed by expanding an anchor hanger comprising a 20-ft joint with five, 1-ft long elastomers wrapped around it. The shoe was drilled out with a 9-7/8 -in. bit to create rathole. Next, a 10.4-in. top-down cone was mechanically driven with drill-pipe weight. The pipe rams were closed and pressure applied below the BOP stack. This helped drive the cone and also applied additional force to expand the bell and elastomers. The stack was stripped through for a portion of the expansion, but the majority of the expansion was achieved mechanically. Drilling continued 300 ft with the 9-7/8 -in. bit and 12-1/4 -in. underreamer. The 9-5/8 -in. monodiameter liner was run. The expansion process was repeated on the second liner. Both monodiameter tubulars were successfully tested to 4,000 psi. Although this was a fairly time-intensive experiment, it is believed that, in the future, this time can be dramatically reduced. For example, a method of using a pre-formed bell (actually, a recessed-ID shoe), threaded to the end of the conventional string and lined with drillable composite material, has been proposed as a way to eliminate the second trip, at least on the first expansion. 1 While the lapping, underreaming, expansion limits and time will all be improved, this experiment proved that subsequent runs of expandable pipe are feasible – the essential ingredient in a monodiameter well. Click here for a complete list of World Oil’s annual expandable technology reports.

|

- Coiled tubing drilling’s role in the energy transition (March 2024)

- Using data to create new completion efficiencies (February 2024)

- Digital tool kit enhances real-time decision-making to improve drilling efficiency and performance (February 2024)

- E&P outside the U.S. maintains a disciplined pace (February 2024)

- Prices and governmental policies combine to stymie Canadian upstream growth (February 2024)

- U.S. operators reduce activity as crude prices plunge (February 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)