Technology from Europe: Technology from Europe:

Italy

Prediction and 3D imaging while drilling by drill-bit 3D RVSP

F. Poletto, L. Petronio, M. Malusa, A. Schleifer, P. Corubolo, C. Bellezza, OGS, Dept. of Geophysics of the Lithosphere; F. Miranda and R. Miandro, Eni E&P; and B. Gressetvold, Read Well Service

3D imaging by drill-bit seismic while drilling (SWD) data was successfully demonstrated in a first survey performed in Sicily in 2000. However, in this first survey, final 3D imaging results were achieved only after the well was completed. Following the experience of this pilot survey, a second 3D “reverse” vertical seismic profile (RVSP) was acquired in another exploration well drilled in Southern Apennines (Italy) in 2002.

In the paper of the same title presented at the EAGE 65th Conference and Exhibition, Stavanger, Norway, June 2 – 5, 2003, the authors presented 3D imaging results obtained and used for prediction while drilling in the new 3D drill-bit RVSP application. This short article summarizes key features of this paper which contains important details and figures.

The goal of this application was achieved by careful organization and day-by-day tuning of the resources and team work. The main steps of the 3D while-drilling survey were: 1) initial and near-surface model definition; 2) acquisition and day-by-day processing; 3) while-drilling tomography and model update; 4) while-drilling Kirchoff migration of 3D data; and 5) interpretation and prediction. Results have been used to support decisions in the well program variation as well as for revision of the geological interpretation.

The well site is located in the Southern Apennines chain, where structural complexity and rough topography determine a poor surface seismic data quality, so a priori definition of the target depth and geological prognosis is difficult. In addition to the exploration uncertainties, high formation instability makes this belt area problematic also for drilling operations.

As a basis for the acquisition planning, a 3D geological model of the area was built, starting from reflection seismic data (2D and 3D), SWD data and log information from two wells drilled near the well site, and up-hole surveys acquired for static correction of the surface seismic data. Other data including short refraction profiles, seismic gun and IVI minivib vibrator were used; and to increase depth of investigation, vibration points were also recorded by 3D SWD channels. Preliminary 2D velocity-depth functions computed for each profile were adopted as an initial model for 3D refraction tomography.

|

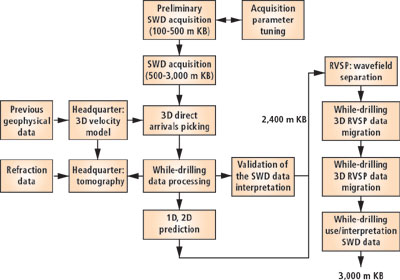

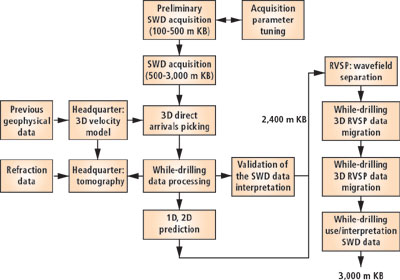

3D RVSP survey: Data and work flow.

|

|

Swd data acquisition and while-drilling processing. SWD acquisition was performed with about 300 channels, deployed along eight radial lines and one irregular circle with “saw-toothed” layout. Acquisition channels were connected with strings of vertical-component geophones deployed along radial patterns of variable lengths. Three components (x,y,z) of geophone were utilized in correspondence of the intersection between radial and circular lines. Reference channels (i.e., pilots) were connected with rig accelerometers, geophones, and pressure meters.

Acquisition was initiated at shallow bit depth to better tune acquisition parameters. 3D SWD monitoring started at 100-m KB depth and was completed at about 3,000 m. The well was vertical, and mainly drilled using roller cone bits with a downhole motor. Data was acquired with alternation of rotary and sliding drilling. A short depth interval was drilled using PDC bits. During the survey, 250 drill-bit depth levels were acquired which correspond to 250 Gbytes of SWD raw data re-processed in the field with online access. Quality control was performed by geophysicists in the field while drilling.

Complex geological features with shallow diffractors and abrupt lateral discontinuities determined complex variations in moveout of the direct arrivals. Different drilling conditions, i.e., rotary and sliding, required an unconventional SWD preprocessing of pilot signals with different delays. RVSP processing and multi-offset VSP common depth point (CDP) mapping was performed while- drilling to provide a look ahead of the bit and prepare daily the separated and de convolved data in input to 3D migration.

The large number of channels (20 km of seismic lines) adopted in this 3D SWD survey required a strong effort to acquire, process and manage the whole dataset. The original paper contains details of the data acquisition process and literature cited references.

While-drilling results. 3D RVSP and multi-offset 2D VSP CDP mapping was utilized to predict geological interface ahead of the bit. This information helped drillers for well-plan execution as well as geologists for geological re-interpretation. At a depth of 2,610 m, hard quartz sandstone caused a slow penetration rate. 3D SWD migration processed at a drill-bit depth of 2,442 m shows the top and the thickness of this unexpected layer.

In the 3D migrated data, at a depth of about 2,980 m, an evident reflection was observed. This predicted discontinuity was apparently not confirmed by changes of main drilling data, such as lithology in cuttings samples and penetration rate. A sonic log acquired at the end of the drilling phase indicated an abrupt P-velocity decrease in correspondence of the strong reflection in SWD data related to a high-porosity zone with gas.

In summary, 3D drill-bit imaging results were achieved while drilling and were demonstrated to be beneficial for drilling and geological interpretation. The same 3D drill-bit data will be further analyzed for subsequent deviation drilling phases.

The authors acknowledged that the work described was partially funded by the European Union within the framework of the Seisbit 3D RVSP project (EC project THERMIE No. OG 278/98h/IT/UK.

|

Technology from Europe:

Technology from Europe: