|

Vol. 224 No. 10 |

Well-visualization software

AnTech Oilfield Software, a division of AnTech Ltd, introduced a major upgrade to StringView Millennium, it’s well-visualization software program, that can interface with existing IT programs to produce custom reports and well diagrams of a broad range of wells. The program has been substantially improved, offering a number of new capabilities: integrated tool editing, making it possible for users to create custom icons from scratch or by modifying an existing tool from the library; new parametric search facility, which allows users to search for tools using any properties, saving time and effort; improved user interface, making it easier to access the specific activities the user carries out most often; increased printing speed; and snap-to-grid capability so that placement of tool strings is more precise. Overall, the new StringView Millennium offers greater speed and an expanded range of capabilities, while retaining its ability to embed seamlessly into any existing IT application. Data may be extracted directly from an existing database and combined with the component library to produce a well diagram, complete with logos and data tables reflecting the user’s designated company product. User-defined parameters may be added to contain existing data in any style, and the well diagram may be modified according to that data.

|

Reservoir simulation

Roxar Software Solutions has release RMSflowsim, a new module in the Irap RMS portfolio, a team tool for geologists and reservoir engineers that improves profitability and productivity by integrating dynamic reservoir data with the static model. This reduces the need for data import and export and allows the user to take advantage of visualization, data analysis and other modeling support tools in the Irap RMS environment. The software is run by a familiar graphical user interface that minimizes the learning curve and increases efficiency, making it the ideal tool for the asset and project team to facilitate exchange of ideas and improve model quality. Geological concepts can be tested easily, and well performance can be predicted, allowing the user to evaluate prospects quickly and screen simulation models prior to full-field simulation. Geologists can effectively produce a higher quality simulation model, test the dynamic properties earlier in the modeling process and improve forward modeling. RMSflowsim is based on proven, reliable technology, and is a fully implicit black-oil simulator with extensive reporting, multi-well handling, group controls, THP control of wells and economic limits. It also comes with extensive pre- and post-processing facilities, including production profiles, P10/P90 comparison across jobs and realizations, composite parameters, etc.

Centrifugal mud pump

The Mud Hog centrifugal pump from Baker SPD is designed for fluid transfer and enhanced fluid movement in the mud systems of all types of drilling rigs. The high-quality bearing configuration contributes to greater life expectancy through improved stability and lower vibration. The wear pad and heavy duty mechanical seals help improve the life of the casing and impeller. The semi-open vane design provides efficient fluid intake and discharge through the power side of the impeller. The impeller is designed with back vanes, which reduces wear on the stuffing box face, and also reduce wear by limiting the inflow of solids to the stuffing box, increasing mechanical seal life. The seal face is highly polished tungsten carbide on tungsten carbide. The Viton bellows allows expansion without binding and provides high temperature resistance. Flexible bellows design allows spring force to easily move seal faces together for extended seal life. The pump’s components are completely interchangeable with other pumps on the market. It is available with a 2-1/2-in. shaft and casing sizes of 3 x 2 x 13-in. through 8 x 6 x 14-in. 1-1/8-in. and 1-7/8-in. shafts are also available. The Mud Hog centrifugal pump from Baker SPD is designed for fluid transfer and enhanced fluid movement in the mud systems of all types of drilling rigs. The high-quality bearing configuration contributes to greater life expectancy through improved stability and lower vibration. The wear pad and heavy duty mechanical seals help improve the life of the casing and impeller. The semi-open vane design provides efficient fluid intake and discharge through the power side of the impeller. The impeller is designed with back vanes, which reduces wear on the stuffing box face, and also reduce wear by limiting the inflow of solids to the stuffing box, increasing mechanical seal life. The seal face is highly polished tungsten carbide on tungsten carbide. The Viton bellows allows expansion without binding and provides high temperature resistance. Flexible bellows design allows spring force to easily move seal faces together for extended seal life. The pump’s components are completely interchangeable with other pumps on the market. It is available with a 2-1/2-in. shaft and casing sizes of 3 x 2 x 13-in. through 8 x 6 x 14-in. 1-1/8-in. and 1-7/8-in. shafts are also available.

Improve plant efficiency

Emerson Process Management unveiled a new PlantWeb website that brings together a wealth of information to help manufacturers achieve more than 2% improvement in efficiency of existing operations and save more than 30% on projects. The site is unique in the breadth and depth of customer results presented, based on Emerson’s worldwide and industry-wide run time with its PlantWeb digital plant architecture. The website contains real customer cases and examples about the quantified business results experienced in installations around the world and across industries. Information on how PlantWeb can deliver operational benefits is presented within each of seven benefit areas that increase plant output or reduce plant costs: quality; throughput; availability; operations and maintenance; safety, health and environment; utilities; and waste/rework. Visitors can also access tutorial white papers addressing each benefit area, which describe each area, the issues that each presents, and the way that PlantWeb addresses them. Links are also provided to customer testimonials and case studies in the Customer Proven section.

Valve alternative for critical flow

Worldwide Oilfield Machine’s Dual-Seal Ball Valve has redundant sealing features that make it ideal for critical flow in remote locations. The valve comes with a primary seal, plus a backup and optional third seal in case of seat damage. If all three seals are destroyed, the valve can be sealant-injected to achieve positive shutoff until repairs can be made. The valve was designed as an alternative to gate and plug valves for a wide range of oilfield production, pipeline and processing applications. Automating the Dual-Seal is less expensive than the linear actuators required by gate valves, and the valve weighs less and operates faster than a gate valve of the same bore. It can also double block and bleed from either direction. The stem seal is self-energized and can be emergency injected if necessary. The valves are available in sizes from 4 to 24-in., in pressure classes 150 through 2500 with a full range of materials and trims. Worldwide Oilfield Machine’s Dual-Seal Ball Valve has redundant sealing features that make it ideal for critical flow in remote locations. The valve comes with a primary seal, plus a backup and optional third seal in case of seat damage. If all three seals are destroyed, the valve can be sealant-injected to achieve positive shutoff until repairs can be made. The valve was designed as an alternative to gate and plug valves for a wide range of oilfield production, pipeline and processing applications. Automating the Dual-Seal is less expensive than the linear actuators required by gate valves, and the valve weighs less and operates faster than a gate valve of the same bore. It can also double block and bleed from either direction. The stem seal is self-energized and can be emergency injected if necessary. The valves are available in sizes from 4 to 24-in., in pressure classes 150 through 2500 with a full range of materials and trims.

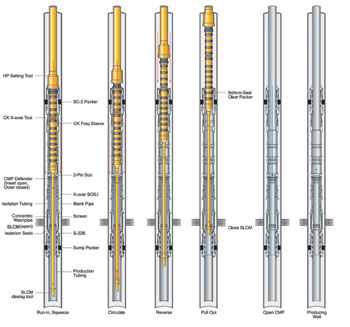

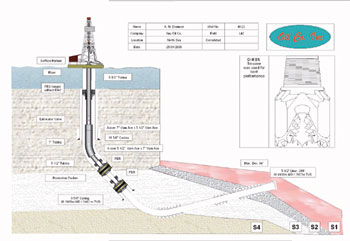

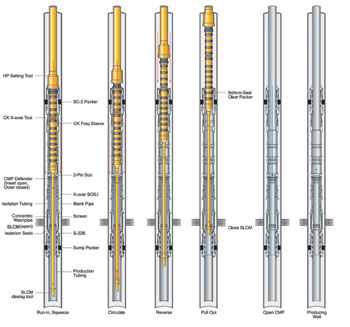

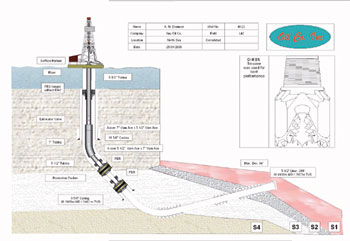

Completion tool prevents fluid loss

A new completion component from Baker Oil Tools improves performance on frac-pack and gravel-pack operations by saving time and preventing fluid loss that can impair well productivity. A common completion practice in Gulf of Mexico frac-packed and gravel-packed wells is the incorporation of a concentric string inside the sand-control screen. A mechanical sliding sleeve built into the concentric string is opened with the sand control service tools to provide returns during gravel placement and then closed to control fluid loss as the service tools are removed from the well. After installing the upper well completion, slickline or coiled tubing intervention is required to open an additional mechanical sliding sleeve to allow production.

|

The new CMP Defender sliding sleeve saves time and reduces fluid loss by allowing the well to be brought on production without slickline or coiled tubing. The tool is a high-performance, pressure-equalizing, non-elastomeric sliding sleeve with a spring-loaded external housing. In the run-in position, it provides positive isolation and pressure containment. A traditional mechanical sliding sleeve run below the CMP provides for returns during gravel placement and fluid loss control after packing. Once the upper well completion is installed in the hole, a single, remote application of surface tubing pressure releases the tool’s outer housing. As the applied pressure is bled off, the spring-loaded housing shifts open to allow the well to produce. By opening when pressure is bled off, the newsleeve can be used for multi-zone completions, with only one tool required per zone. After actuation, the sliding sleeve can be mechanically manipulated to control production from the well, if required.

Reporting and data management solution

Landmark Graphics Corp. has released OpenWells, a next-generation technology for wellsite operations reporting and analysis. OpenWells is a fully integrated, comprehensive operations reporting and engineering data management solution that offers both drilling and well services reporting. This technology is a user-configurable operations data management tool that integrates directly with well engineering and earth model visualization applications. It has been fully engineered and integrated to support rapidly expanding real-time drilling environments from shallow, onshore fields to deepwater frontier areas. Configurable for any type of drilling or well services operation across a wide range of environments, the system provides a customizable data management tool. It can be configured to meet the specific reporting needs of an operator, increasing data integrity and reducing cycle-time through tight integration with drilling engineering applications. Drilling, completions and well servicing information are provided within a single application.

Sealless gear pumps

Viking Pumps’ new line of Mag Drive Magnum sealless pumps features a thrust-controlled design that allows short-term run-dry capabilities. This all but eliminates damage from priming and empty tanks. The cast-iron, reversible-flow pumps are suited for hazardous or hard-to-seal liquids, and when very low maintenance is required. The adjustable rotor clearance enables high volumetric efficiency, whether pumping thin or viscous liquids.

|

The Mud Hog centrifugal pump from Baker SPD is designed for fluid transfer and enhanced fluid movement in the mud systems of all types of drilling rigs. The high-quality bearing configuration contributes to greater life expectancy through improved stability and lower vibration. The wear pad and heavy duty mechanical seals help improve the life of the casing and impeller. The semi-open vane design provides efficient fluid intake and discharge through the power side of the impeller. The impeller is designed with back vanes, which reduces wear on the stuffing box face, and also reduce wear by limiting the inflow of solids to the stuffing box, increasing mechanical seal life. The seal face is highly polished tungsten carbide on tungsten carbide. The Viton bellows allows expansion without binding and provides high temperature resistance. Flexible bellows design allows spring force to easily move seal faces together for extended seal life. The pump’s components are completely interchangeable with other pumps on the market. It is available with a 2-1/2-in. shaft and casing sizes of 3 x 2 x 13-in. through 8 x 6 x 14-in. 1-1/8-in. and 1-7/8-in. shafts are also available.

The Mud Hog centrifugal pump from Baker SPD is designed for fluid transfer and enhanced fluid movement in the mud systems of all types of drilling rigs. The high-quality bearing configuration contributes to greater life expectancy through improved stability and lower vibration. The wear pad and heavy duty mechanical seals help improve the life of the casing and impeller. The semi-open vane design provides efficient fluid intake and discharge through the power side of the impeller. The impeller is designed with back vanes, which reduces wear on the stuffing box face, and also reduce wear by limiting the inflow of solids to the stuffing box, increasing mechanical seal life. The seal face is highly polished tungsten carbide on tungsten carbide. The Viton bellows allows expansion without binding and provides high temperature resistance. Flexible bellows design allows spring force to easily move seal faces together for extended seal life. The pump’s components are completely interchangeable with other pumps on the market. It is available with a 2-1/2-in. shaft and casing sizes of 3 x 2 x 13-in. through 8 x 6 x 14-in. 1-1/8-in. and 1-7/8-in. shafts are also available.  Worldwide Oilfield Machine’s Dual-Seal Ball Valve has redundant sealing features that make it ideal for critical flow in remote locations. The valve comes with a primary seal, plus a backup and optional third seal in case of seat damage. If all three seals are destroyed, the valve can be sealant-injected to achieve positive shutoff until repairs can be made. The valve was designed as an alternative to gate and plug valves for a wide range of oilfield production, pipeline and processing applications. Automating the Dual-Seal is less expensive than the linear actuators required by gate valves, and the valve weighs less and operates faster than a gate valve of the same bore. It can also double block and bleed from either direction. The stem seal is self-energized and can be emergency injected if necessary. The valves are available in sizes from 4 to 24-in., in pressure classes 150 through 2500 with a full range of materials and trims.

Worldwide Oilfield Machine’s Dual-Seal Ball Valve has redundant sealing features that make it ideal for critical flow in remote locations. The valve comes with a primary seal, plus a backup and optional third seal in case of seat damage. If all three seals are destroyed, the valve can be sealant-injected to achieve positive shutoff until repairs can be made. The valve was designed as an alternative to gate and plug valves for a wide range of oilfield production, pipeline and processing applications. Automating the Dual-Seal is less expensive than the linear actuators required by gate valves, and the valve weighs less and operates faster than a gate valve of the same bore. It can also double block and bleed from either direction. The stem seal is self-energized and can be emergency injected if necessary. The valves are available in sizes from 4 to 24-in., in pressure classes 150 through 2500 with a full range of materials and trims.