Geophysical Applications

4D seismic on demand is the goal

The usefulness of 4D is not in dispute, but ideas are still evolving as to which factors produce the most cost-effective and reliable results

Alastair Hay, Concept Systems, Edinburgh, UK

When will the E&P industry fully embrace 4D seismic? Sooner rather than later. The issue is less a question of technology, but more a question of putting the right 4D package together. It is probably the mindset more than anything else that is holding back the adoption of 4D marine seismic surveying as a routine operation in the oilfield cycle. Fifteen years ago, 3D seismic exploration was at a similar crossroads, regarded as an expensive and not fully proven option, the preserve of majors rather than the norm for any size oil company anywhere.

In fact, we may be much closer to realizing the full potential of 4D seismic than present sentiment would indicate. The technology is maturing quickly, and we seek to show herein that solutions already exist for many of the perceived problems, and other outstanding issues are within the industry’s grasp to resolve. The trick is to convince oil companies that building 4D seismic into the planning and operation of oilfield developments has a huge upside in terms of reservoir value.

BACKGROUND

As a serious concept, 4D seismic began to emerge in the mid-1990s, with high-profile early experimentation carried out by BP on its Foinaven field, west of Shetland. The crucial requirement to image the movement of hydrocarbon fluids over time was for the parameters of the first and subsequent surveys to be as similar as possible. If this was achieved, then the results could be used to target drilling and other measures to optimize production, with a potentially substantial pay-off in terms of additional recoverable reserves.

To date, three major techniques have emerged for marine 4D seismic acquisition, namely, conventional streamer, ocean bottom cable (OBC), and permanently installed OBC. The choice of technique is dependent on many factors, some technical, some environmental, but mainly economic. Although there are clear technical advantages to OBC in terms of improved, repeatable images, especially with permanent installation, it is much more expensive. In due course, one can anticipate that permanently installed OBC, which allows frequent surveying over a targeted reservoir with quick results, will be what oil companies shoot for, but that time hasn’t quite arrived.

With cost in mind, streamer-acquisition of repeat 3D surveys (i.e., 4D) has emerged as the most popular short-term option for oil companies that want to benefit from the technology now. Results from streamer-acquired 4D are improving, but some target areas may have significant environmental factors such as tides, weather and current that can compromise the usefulness of the technique.

4D seismic is not simply an extension of 3D seismic techniques. It has its own criteria requiring new approaches and techniques, some of which are only at the theoretical stage and the subject of development by oil companies and contractors. The core tools that support the planning, acquisition and quality control of 3D seismic have served the industry well for the past decade. These tools are complex and have allowed the marine seismic industry to take it for granted that many of the problems associated with 3D acquisition in the early days, such as navigation downtime, turn optimization and two-vessel operations, have now been addressed.

One clear aspect of 3D seismic is that its processes tend to be people intensive. Typically, the instrument rooms are heavily manned with navigators, observers and processors. If 4D seismic on demand is to become a reality, then many of these processes will need to be more automated with operator intervention only where problems arise.

The usefulness of 4D is not in dispute, but ideas are still evolving as to which factors need to be considered to produce the most cost-effective and reliable results. As oil company geoscientists explore the possibilities, they are investing in new tools and services that have the potential to reach their goal. This is in keeping with the pattern that was established when 3D seismic emerged. All the ingredients for cost-effective 4D seismic are within reach, and many of the same principles used for towed-streamer technology can be applied to make OBC more accessible and, ultimately, the technology of choice.

IMPROVING TOWED-STREAMER 4D

To carry out time-lapse investigations, a fundamental requirement is to have a baseline with which to compare subsequent surveys. This is not just a case of blowing the dust off the original survey. Many companies may find it difficult to access or recreate baseline data sets. The value of accurate data cannot be underestimated, and horror stories abound of surveys being shot away from the assumed target because of poor geodetic information. The underlying problems of completeness and geodesy in historic data sets can be addressed with effective data management techniques.

The message for 4D seismic is that during the planning phase, there are numerous considerations to take into account, of which data management is just one aspect. For example, differences in the new 4D acquisition geometry can lead to repeatability problems. These inconsistencies can arise when the new data is likely to be acquired with more economic (e.g., dual source, 6 – 10 streamer array) acquisition geometry than an original baseline survey shot 10 years ago with a more basic geometry (e.g., single source, two streamers).

Differences can also occur because the baseline acquisition was shot in a clear pre-production area uncluttered by production facilities, while subsequent surveys must be designed around these installations. This may involve complex undershooting. In either of these cases, the impact of design decisions on repeatability has to be measured and understood. In addition, post-mortem analysis of previous 4D datasets, from similar geographic (or geological) areas with a known set of 4D seismic results, can be helpful in providing a detailed understanding of the potential issues and how they might impact the planned 4D acquisition.

Illumination. In addressing the potential flaws in 4D seismic over the last two years, Concept Systems has been developing an illumination analysis technology known as Illuminator. This patented technology is designed to allow a geophysicist to analyze subsurface coverage using Common Reflection Point (CRP), as opposed to Common Mid Point (CMP), along with associated outputs including CRP-CMP deviations, offset, azimuth, travel times, angle of incidence, amplitudes, etc. Armed with this information, a geophysicist can analyze the likely impact on the final dataset of different design parameters and geometries.

Illumination can be applied at the planning stage to assess the effect of streamer configurations on the target acquisition. It may be that the baseline was shot some years ago and the streamer configuration was not as extensive as can be achieved using current technology. Illumination can provide an understanding of these effects to ensure that the value of the new survey is maximized.

During surveys operations, the technique is designed to provide the results of ray tracing much faster than conventional systems. Illumination analysis of complex structures, revealing CRP fold maps, can be obtained within minutes as opposed to days or weeks. The major benefit is that geoscientists can identify the gaps in seismic coverage while the vessel is still on station and can order it to go back over sections again. This infill technique eliminates much of the otherwise unavoidable guesswork at the processing stage, is no more complex to carry out than conventional CMP analysis, and is simple from an operational perspective. The infield operator does not require detailed understanding of geophysical models, velocity volumes, ray tracing, and so on.

Repeatability analysis. The key is repeatability analysis, which means an adjustment to the usual focus in 3D seismic surveys on “steering for coverage,” a well-enough understood concept among geophysicists. Normally in a 3D seismic survey, the use of binning tools allows coverage decisions to be made in near-to-real time. Clearly, coverage is just as important in a survey being shot for 4D purposes, but until recently, there was no clear consensus as to whether there needed to be more attention paid to this.

What has become clear is that in 4D surveys, providing close matching with the baseline is of great importance. This requirement should drive a different approach to how infill is acquired. Infill should be used not only to improve coverage, but also to improve matching.

Conventional 3D seismic acquisition makes use of CMP-based binning analysis, where crews steer the vessel for coverage, using real-time binning displays to assist them. Infill is usually specified in a survey contract to fill any offset holes that exceed the stated limits; e.g., steering corrections made to counter feather effects can lead to improved coverage but can have significant consequences on dataset repeatability.

When shooting 4D for repeatability, the way an acquisition program is managed must change. Analysis of repeatability, rather than purely analyzing CMP coverage, becomes a critical focus, which is where techniques such as illumination technology come into play. This is not to overlook QC comparisons of the underlying differences between datasets. Detailed analysis of the vessel/source tracks, feather matching and attribute differences (e.g., source/streamer depths, source pressure/volume, positioning quality, etc.) significantly add to understanding the relevant differences.

At the processing stage after survey acquisition, a geophysicist can again make use of the illumination results to determine the initial quality of survey repeatability and improve the matching potential of different data sets.

APPLICATION EXAMPLE

Two years ago, Shell Expro was seriously looking at the contribution 4D seismic could make on decision-making for reservoir management, and invited Concept Systems to work on an R&D project.

One of the key problems was how to reliably measure repeatability of seismic acquisition. As already discussed, 4D projects often produce results where non-4D artifacts make the data difficult to process and results difficult to interpret. It was believed that a significant portion of this error was being introduced by the difficulty in accurately repeating the original acquisition. Factors including geometry changes, weather, tides, etc., all played a part in producing errors. To perform a viable analysis, it was realized that a detailed knowledge of the underlying distribution of data would be required. Reflex, the service company’s proprietary binning technology, seemed to offer an ideal platform for managing such repeatability analysis.

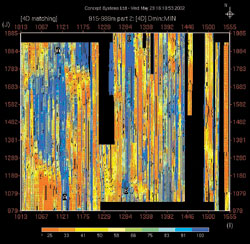

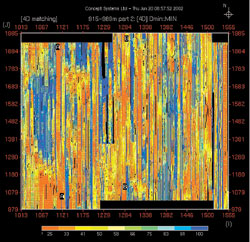

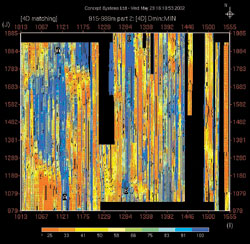

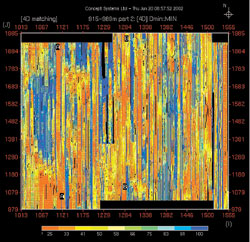

The flexibility of the database design allowed fast tracking the development, giving Shell access to functionality within weeks of initial discussions. The technology was delivered via a services model, taking advantage of the contractor’s personnel and their knowledge of navigation data. The results were delivered on a dedicated, secure services website within turnaround times agreed to with the geophysicist. This allowed the geophysicist to highlight areas of poor repeatability and understand the reasons – giving time to acquire infill targeted at optimizing the 4D dataset, Fig. 1.

|

|

Fig. 1. Left, repeatability before infill, lines A-A, B-B marked as requiring additional infill to improve repeatability. Right, repeatability improved after infill.

|

|

OBC CONSIDERATIONS

Whether a temporary or permanent OBC survey, the location of each sensor should be precisely known and more controllable than with streamer acquisition. Measurement of the repeatability (of both shots and receivers) is still critical. The drive here will be on reducing the amount of time between the acquisition survey and having interpreted results available for asset management.

While permanently installed cables and sensors reduce some of the factors that affect repeatability, some issues still remain. When planning 4D acquisition, repeatability analysis can help take these into account. For example, illumination studies may again prove effective. If seabed receivers fail, they will not be cheap to retrieve and fix. The decision to do so may be based on the impact on subsurface illumination caused by the loss of the devices. It is a case where illumination can be performed to model whether acquiring additional shots would get around the problem and indicate where the shotpoints should be.

As with towed-streamer surveys, the major emphasis in repeated OBC surveys needs to be on streamlining and automating the whole operation. For fields that display characteristics that make them suitable for permanent OBC installation, surveys are more likely to be frequent, possibly several times in a year. For this to occur, there must be a step change in the time taken to deliver processed seismic data, so that production decisions can be made in a timely fashion.

There are clear process advantages in building seismic into the production environment. For fields which have a permanent array, seismic is already budgeted, the layout has been planned with the baseline survey, and the tendering can be done on a per field rather than per survey basis (as in production contracts). Scheduling is not a problem either, because only a ship of convenience is needed, and navigation is not an issue, as you have no streamers to position, just a GPS over the guns, and the seismic processing parameters are known. These elements contribute to the streamlining of processes before effort is expended on automating the shooting process, providing automatic QC of navigation and seismic data, and accelerating delivery of an assured product to a repeatable seismic processing operation.

THE CHALLENGE AHEAD

The major bottlenecks in existing processes (time to plan, time to mobilize, acquisition, processing) must be analyzed and improved. There are many examples where these techniques have been applied in other industries. JIT manufacturing, production automation, supply-chain management and knowledge management are all mature approaches from which much can be learned. The seismic industry must look to this experience and challenge existing practices to meet the requirements for 4D seismic on demand. In the world of permanent OBC 4D, companies should be aiming to deliver the processed results within two months.

THE AUTHOR

|

| |

Alastair Hay is a graduate in electronics from Edinburgh University. He has been involved in the oil industry for more than 25 years, beginning his career working with ROVs in the mid-’70s. He became involved with navigation and positioning at Geofix, where he was technical director from 1979 to 1983. He co-founded Concept Systems in 1983, where he is managing director. Concept began assisting seismic contractors with 3D marine seismic during the ’90s, and now controls navigation and related processing for 80% of the world’s seismic fleet.

|

| |

|

|