Technology from Europe: Technology from Europe:

Norway/Sweden

Scale inhibitor squeeze life extended through bridging

Norway’s Heidrun field is 175 km (109 mi) offshore the coast in the Haltenbanken area, and has produced oil from a TLP since 1995. Yet, the field has presented a challenging scaling environment to operator Statoil, due to high barium content in formation water, the use of seawater for pressure maintenance and the clay-rich sandstone. The latter generates a significant amount of fines during normal and unplanned operations. Scale control began in November 1999 with regular squeeze treatments.

Aqueous and non-aqueous scale inhibitor treatments have been performed at Heidrun. These treatments have included phosphonates, phosphate esters, polymers and an unusual phosphorus end-capped co-polymer. In most cases, application of the squeeze treatment has caused an increased mobilization of reservoir fines, leading to plugging in the gravel packs and thus reducing PI (liquid productivity index).

In answer to the problem, a joint R&D program between Statoil and Champion Servo has identified an additive that provides enhanced adsorption of the scale inhibitor and an acceptable amount of fines stabilization. Laboratory studies have shown that the additive can increase adsorption of a range of different scale inhibitors on crushed, Heidrun core material. Also, this additive reportedly provides better scale inhibitor release characteristics in core flood tests. The tests indicated that the additive contributes a noticeable level of scale inhibition that may complement the amount already provided by the scale inhibitor.

In the field, a number of generically different scale inhibitors have been squeezed on Heidrun wells A28 and A-52 (with other wells used as controls), as part of the evaluation. Field trials have shown that the additive can extend scale inhibitor treatment life and reduce fines mobilization.

|

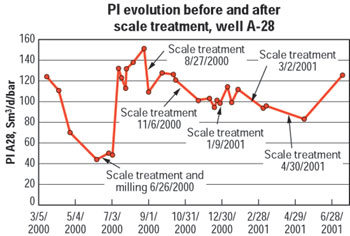

When the multi-functional additive was used on well A28, PI would fluctuate moderately, yet the scale squeezes did not significantly, negatively impact PI. Thus, the additive reduced clay particle migration.

|

|

Simulation data generated by using Squeeze V indicated that higher K and n values and a lower r2 value (Freundlich parameters) were needed to match the field treatment utilizing the additive. This is in opposition to values required to match the treatment performed without the additive. Such findings suggest that more adsorption takes place, but at a slower rate when in the presence of the additive.

Use of the additive, as part of a pre-flush treatment before the main scale inhibitor pill in Heidrun wells, has generated a 50% average increase in treatment life. This reduced the annual frequency of squeeze treatments on well A28 from 18 to 12. Consequently, the well’s availability shot up 60% to 70%, compared to the previous 40% to 50%.

Not surprisingly, given a well that produces 1,000 cu m/d of oil (6,290 bopd), there is an annual gain in oil output of about 72,500 cu m (456,025 bbl, or 1,249 bopd) per well. At the crude oil price level (NOK195.25/bbl or US$25/bbl) in effect at the time of this study, this extra value derived on one well, alone, was more than NOK90 million (US$11.5 million).

ACKNOWLEDGMENT

This article is derived from SPE Paper 80377, presented at SPE’s 5th International Symposium on Oilfield Scale in Aberdeen, Scotland, Jan. 29–30, 2003.

|

Technology from Europe:

Technology from Europe: