April 2003

Special Focus

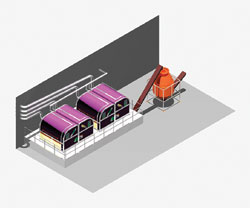

Norway/Sweden: Field evaluation shows rotating separator viable alternative to shale shakers

Vol. 224 No. 4 Technology from Europe: Norway/Sweden Field evaluation shows rotating separator may be an alternative to shale shakers Environmental requirements for operations on the Norwegian Continental Shelf (NCS), when drilling with o

- Advancing offshore decarbonization through electrification of FPSOs (March 2024)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- Driving MPD adoption with performance-enhancing technologies (January 2024)

- Digital transformation: A breakthrough year for digitalization in the offshore sector (January 2024)

- Offshore technology: Platform design: Is the next generation of offshore platforms changing offshore energy? (December 2023)

- 2024: A policy crossroads for American offshore energy (December 2023)

Technology from Europe:

Technology from Europe: