Satellite-based alarm system saves compressor operators time and money

Satellite-based alarm system saves compressor operators time and moneyJames Barr, * J-W Operating, Addison, Texas; Steve Watwood and Bruce Bacon, American Millennium Corporation, Inc. (AMCI), Golden, Colorado; and Curtis Roys, ** CC Technology, Midland, Texas Bottom line. To decrease false alarms and unreliable notification of compressor downtimes, J-W Operating (JW) installed magnetically-attached, vibration sensor, satellite-based alarm systems on more than two dozen compressors in their field operations, starting in 1999. Several have been on location more than two years without a single problem, and J-W has not had to replace the first set of batteries. J-W has installed an additional 12 units on compressors that they monitor for others. Eliminating just a few hours of downtime pays for the low-cost ($1,600 installation, plus $30 to $40/month for air time) service. Due to utilizing the geo-synchronous satellites, there are no blind spots; the system is always up. Problem addressed. With alarm systems based on signal or cellular service, operators often experience problems with false alarms and unreliable notification of downtime, due to loss of signal or such service. Hard-wiring for sensors and communications is often cost-prohibitive. Low-altitude satellite communication can have "blind" spots and/or have time windows of unavailable coverage. Evolution of alarm/communication systems. Site visitation was the preferred method of surveillance until the advent of automated systems. Except for areas of concentrated production, automated systems requiring land lines are cost-prohibitive. Cellular service evolved to become an option for areas with cellular coverage and areas without line-of-site issues. However, coverage was not available in many remote areas. Low-altitude satellites that have become available in recent years solve some of the coverage problem but leave time windows of unavailability. Innovative, cost-efficient automation devices, when coupled with higher-altitude geo-synchronous satellite systems, have made remote, site alarm systems practical. The technology. American Millennium Corporation, Inc.’s (AMCI) SatAlarm-Sentry system is a GEO satellite-based system that does not require a dish antenna, complicated installation or even site power. The callout system is totally contained in a 3 x 9 x 11-in., Kydex 550 plastic enclosure. The housing includes all antennas, hardware and batteries. The latter usually last more than three years. Vibration sensor installation is simple – attach it magnetically to the compressor and point it toward the sky, enabling it to communicate with the satellite. If a customer wants to collect more data, the unit does have three other digital I/Os and an analog input available through an external connector. The simple mounting of a unit to a compressor is demonstrated in Fig. 1.

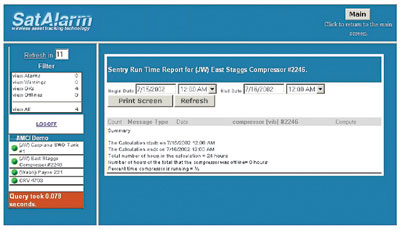

A proprietary, vibration-sensing circuit is used to identify a compressor or other asset’s operational status. The adjustable sensing circuit ranges from extremely sensitive to a robust vibration setting. It can detect the start-up of a gas compressor engine, even while an electric-driven cooler is running on the same skid. The circuit’s sensitivity can be adjusted if there are multiple compressors on-site, so that only one compressor’s operating conditions are transmitted. Satellite coverage is provided from the Northwest Territories of Canada to the northern countries of South America. The entire continent of South America is scheduled to come online early in 2003. Global positioning satellite (GPS) service is also included in the product, making asset tracking convenient. The system even has a sophisticated web-mapping engine that will route from any address to the asset site, providing a highlighted map and even written directions. The customer’s data are available through a password-protected website. Runtime reports, location tracking for mobile assets, and history reports are available and printable. The web-based software allows users to export the asset’s data into Microsoft Excel to display graphs or charts. Customers have the option of receiving alarm data via a customized website, and/or through an answering service. When an alarm goes off, the message is sent to the firm’s answering service and forwarded to the customer’s contact list. Then, AMCI receives an acknowledgment that the customer knows the compressor is down. Notifications can be by e-mail, fax, pager, cell phone with text messaging, PC, and/or phoning. The entire notification processing takes only a few minutes. The website display format is displayed in Fig. 2.

For those receiving notification via PC, the display page is split in half. One-half of the page – an entire listing of a customer’s compressors – refreshes every two minutes to show new alarms. The other half of the page shows site specifics on one selected compressor at a time. Incoming alarms can also be audibly announced. Field units can be programmed to "check in" at a particular time each day, to report the compressor’s current status, temperature and battery. If daily reports are not received, e-mails are issued to company personnel within an hour of the stated check-in time. If a unit is supposed to check in and does not, an internal system watchdog alerts AMCI that there may be a problem that needs to be addressed. Asset detail on the screen’s right side illustrates the "last known status," including battery voltage, site temperature, unit serial number and customer-selected behavior settings. A complete history of the compressor’s status is recorded, including all starts, stops, status data, and notification and acknowledgement history of each alarm. History is stored from the first day that a unit is installed and activated. Report detail includes percentage of run time, and how long a unit is down on every start-up and shutdown. Curtis Roys, President of C C Technology, reported that the unit has opened the door for simple installation and dependable call-out monitoring of all remote and local equipment. The unit can be provided on a 30-day, free-trial basis, to determine if the application fits the needs. A demonstration of the compressor application reporting can be found at www.amc-wireless.com and linking the SatAlarm-Sentry log-in. Username: Demo; Password: Demo. PTD

|

||||||||||||||||||||||||||||

- What's new in production (February 2024)

- Prices and governmental policies combine to stymie Canadian upstream growth (February 2024)

- U.S. operators reduce activity as crude prices plunge (February 2024)

- U.S. producing gas wells increase despite low prices (February 2024)

- U.S. drilling: More of the same expected (February 2024)

- U.S. oil and natural gas production hits record highs (February 2024)