Technology at Work: Recent advances in cased-hole logging, sidetracking mills and CO2 pumping

Feb. 2002 Vol. 223 No. 2 Feature Article TECHNOLOGY AT WORK Recent advances in cased-hole logging, sidetracking mills and CO 2 pumping E. Lance Cole, Nat

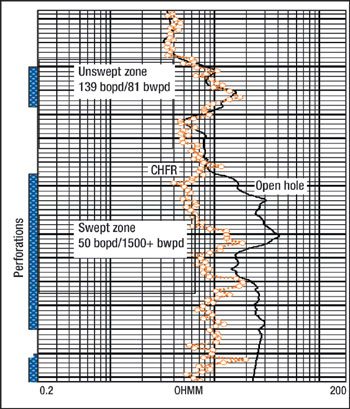

TECHNOLOGY AT WORKRecent advances in cased-hole logging, sidetracking mills and CO2 pumpingE. Lance Cole, National Project Manager, Petroleum Technology Transfer Council (PTTC) Technology advances are occurring across the spectrum of E&P operations. Some are revolutionary, while others are incremental – but all are providing producers with improved efficiency and/or costs. This article highlights three such advances: 1) through-casing resistivity logging using Schlumberger’s CHFR tool; 2) one-trip milling and lateral drilling using PDC Bimills; and 3) adaption of the RedaHPS* horizontal pumping systems from Schlumberger for CO2 pumping. And recent recipients of PTTC’s technology transfer awards are noted. Through-casing resistivity. For decades, industry has worked toward developing tools that would reliably measure formation resistivity through casing. Continued R&D and technology advances that enable reliable measurement of voltages in the nanovolt range led to today’s tools. Schlumberger commercialized its Cased Hole Formation Resistivity (CHFR) tool in 2000. The company’s Bob Davis, speaking during a recent PTTC workshop in California, presented resistivity data from a new well that had been logged open-hole, and with the CHFR tool after casing was set. Visually, the curves were close overlays. Differences that were noted could be explained by the much deeper depth of investigation from 7 to 32 ft with the CHFR tool. The 3-3/8-in., 43-ft-long tool can be run in 4-1/2 – 9-5/8-in. OD casing in any borehole fluid. The technology behind the system dictates that measurements be made while stationary. Initial tools required 2 min. to make two measurements at 2 ft intervals, equating to 120 ft/hr. Work is progressing that would allow logging 200+ ft/hr. Vertical resolution is about 4 ft. Davis presented log data from several wells in the San Joaquin, Ventura and Los Angeles basins of California, showing how the data was used for flood monitoring and looking at potential of behind-pipe zones. He noted that recompletion intervals were found about half of the time. In one instance, a well producing 30 bopd and 1,500 bwpd had been shut-in since 1998. Less than one month after recompletion in an unswept zone found behind pipe, the well was producing 139 bopd and 81 bwpd, see accompanying figure. The following quote illustrates the value one client attributes to using CHFR technology: "Behind-casing resistivity measurement is the only logging tool to successfully discern oil and water in the XXX waterflood. Between six and twelve wells managed by the YYY reservoir management team will be logged with the cased-hole tool this year. Every wet well is now reviewed as a candidate for this surveillance technology."

Cost-effective recompletions with PDC technology. Sidetracking mills designed with polycrystalline diamond cutter (PDC) insert cutting structures are being used to mill casing windows and drill required laterals in the Fruitland formation coalbed in the San Juan basin. The technique reduces the number of trips, equipment, costs and time required to recomplete wells. Downtime is reduced, so wells can be brought on-line sooner. Data was shared for recompletions in three Fruitland formation wells (SPE 71052) using the PDC Bimill in Smith Services’ "Drill Ahead System." On the first recompletion, 60 hr of operational time were saved vs. prior practices, and the well was returned to production two days earlier, producing 2 MMcfd. The Drill-Ahead system saved two trips, resulting in safer and more economical rig operations. These three San Juan basin recompletions, plus other applications in Texas, Louisiana, Columbia and Oman, prove the technology can be successfully applied. This approach decreases the number of trips required; saves time and money; and reduces wear and tear on drilling equipment. Horizontal systems for CO2 pumping. In the 2001 CO2 Conference in Midland, Texas, in early December, Pete Schroeder with Schlumberger, REDA Production Systems, described a new alternative for CO2 pumping. Conventional choices include split-case pumps, a plunger pump and a vertical turbine pump. All are proven technology, but all have shortcomings. Schlumberger has adapted the RedaHPS horizontal pumping systems for CO2 pumping. Modifications from the standard HPS pump include a custom seal, custom elastomers, custom pump bearings, and a high-pressure intake. Advantages include low capital cost, a stand-alone system requiring no support systems and simple (only one Champion seal) sealing technology. With its simplicity, lead times on unit and pump rebuilds are shorter, and maintenance is less burdensome. Routine maintenance requirements are: quarterly (motor grease and unit inspection); bi-annual (thrust chamber oil change and vibration analysis); and annual (alignment analysis). An HPS unit has been operating in an ExxonMobil field since January 2000. The 50-hp HPS CO2 unit, pumping 350 gpm (2,100-psi intake, 125-psi boost), has operated reliably. Except for six weeks downtime due to downstream piping issues, the only non-routine maintenance has been to replace a weeping stainless steel tee fitting on the seal. It has proven to be another successful migration of conventional oilfield technology. West Coast technology transfer awards. Each year, PTTC’s West Coast Region recognizes individuals or companies for technology transfer accomplishments – in this case, developing technologies that regional industry is using and seeing great value. 2001’s recipients, recognized during the West Coast Anniversary Forum on December 7 in Los Angeles, were: Downhole Video International for its downhole video camera, and Schlumberger for its GHOST (Gas Holdup Optical Sensor Tool). The GHOST tool enables direct detection and quantification of gas in multiphase flows. For both technologies, a regional producer vouched for the impact in its operations. Awardees are selected by PTTC’s West Coast Producer Advisory Group. Dr. Iraj Ershaghi, University of Southern California, who leads the West Coast PTTC program, was also recognized by PTTC for his tireless efforts on behalf of industry. |

- Coiled tubing drilling’s role in the energy transition (March 2024)

- Using data to create new completion efficiencies (February 2024)

- Digital tool kit enhances real-time decision-making to improve drilling efficiency and performance (February 2024)

- E&P outside the U.S. maintains a disciplined pace (February 2024)

- U.S. operators reduce activity as crude prices plunge (February 2024)

- Drilling advances (January 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)