Surface geochemical survey adds exploration confidence

Surface geochemical survey adds exploration confidenceWilliam H. Shepherd, Oil Producers Inc., Wichita,

Kansas, and J. Lynne Davison*, Pangaea Geochemical Technologies, Inc., Wichita,

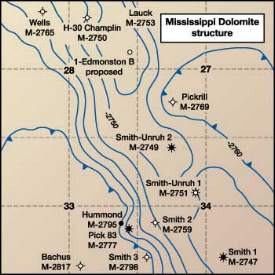

Kansas Bottom line. Surface-hydrocarbon-soil-gas data provided extra confidence that adequate reservoir quality existed at a step-out drilling location of a structural / stratigraphic-controlled Mississippian dolomite play. Data were gathered using patented K-series gas-sieve technology from Pangaea Geochemical Technologies, which concentrates soil gas readings and provides greater discrimination. Field history. Oil Producers Inc., based in Wichita, Kansas, planned additional development drilling for 5,250-ft-deep Mississippian dolomite gas production in selected leases in Kiowa County, Kansas. Like most area operators, Oil Producers relies heavily on Mississippi-formation structural maps when selecting location; but structure alone is not sufficient for locating the stratigraphically-controlled, gas-bearing dolomite stringers. Experience, intuition and luck are also needed. Wanting to further improve its odds for success, the operator was open to considering data from additional tools. Light-hydrocarbon, surface-geochemistry data, gathered with special K-series gas-sieve technology, identified areas of favorable production potential. In the area of interest, the operator had drilled and completed two Mississippi dolomite gas producers – the Smith-Unruh 1 (early 1998), followed by the Smith-Unruh 2 (early 1999). Combined cumulative production to early January 2000 from the two wells was 250 MMcf of gas and 1,000 bbl of oil. Together, the wells now produce 500 Mcfd and 3 bopd from the solution gas drive reservoir. Consistent with drillstem tests, the Smith-Unruh 1 has been the better producer – having generated about 70% of the cumulative total and producing 60% of the current output level. Together, the wells have produced enough to achieve payout. Oil Producers planned additional drilling on the northwest-trending Mississippi structural feature where the two wells were located, Fig. 1. Considering all available geological data, it had selected the 1 Edmonston B location. But considering the proximity to two dry holes, it was open to considering other data that might add confidence to its well location decision.

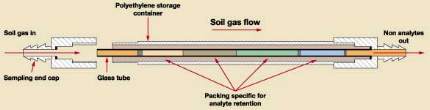

K-series gas-sieve technology. During this time interval, Pangaea was performing many field surface geochemical surveys near proposed drilling locations throughout Kansas as part of its 1999 "Red Top Program," a field R&D project awarded to the company by the Kansas Technology Enterprise Corp. Pangaea approached Oil Producers, maintaining that a surface-geochemical, light-hydrocarbon survey using its K-Series gas-sieve technology would provide sufficient sensitivity to identify reservoir areas prone to gas production. Oil Producers assented, and Pangaea designed and conducted a 32-point surface-geochemical survey. The K-series gas-sieve analysis is more sensitive because its sample size (1,000 ml) compensates for the noise experienced with typical 2–10 ml soil-vapor samples. With the gas sieve (Fig. 2), 1,000 ml of soil vapor is collected from 8–10 ft below the surface and pumped across the gas sieve.

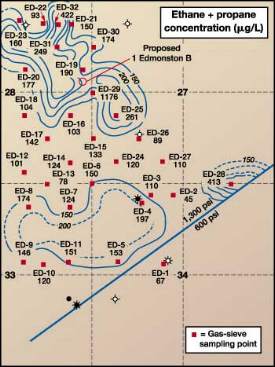

The molecular sieve packed inside the gas sieve does not trap smaller molecules such as water, carbon dioxide, nitrogen and oxygen, but preferentially traps and concentrates hydrocarbon vapors. For analysis, the gas sieve is attached to a gas chromatograph (GC) and the hydrocarbons are thermally desorbed. Concentration of the light hydrocarbons – methane, ethane, propane and butane – are determined by a flame ionization detector. Geochemical survey and interpretation. In August 1999, soil-vapor samples were collected from the planned 32 locations using Geoprobe vapor sampling equipment. Hydrocarbon-soil-gas concentrations were then measured using GC-thermal desorption techniques. Reservoir pressure, which influences the amount of surface geochemical expression, was known to be different – 600 psi in the Smith-Unruh 1 versus 1,400 psi in Smith-Unruh 2. Thus, surface expression around the Smith-Unruh 2 could be expected to be higher. The 1,029-Btu Mississippian gas contains 3.78% ethane, 1.39% propane and 0.391% N-butane. Because butane occurs in such small concentrations, only ethane and propane values were used for interpreting the location of gas-prone areas. Methane was not evaluated because soil bacteria – which do not produce ethane, propane or butane – commonly produce methane in varying quantities. Methane data could become useful if carbon ratios were determined and the percent of modern biogenic gas was known. Ethane and propane concentrations at 32 sampled locations are given in Fig. 3. This isoconcentration map illustrates where light hydrocarbons are emanating from the reservoir in the greatest amount. Concentration in the area of Smith-Unruh 1 was 67 µg/l, reflecting good reservoir quality even though reservoir pressure was lower. Ethane and propane value at the Smith-Unruh 2, which was known to be a lower quality producer even with higher pressure of 1,300 psi, was 197 µg/l. Considering this data, values of 197 µg/l, or higher, were considered necessary for a location to be an attractive drilling candidate. Using these criteria, the geochemical data confirmed that the proposed Edmonston location would be favorable.

The ethane and propane concentration data also suggest that the Smith-Unruh 2 is separated from the Edmonston area. Considering the nature of the reservoir, it is likely that it is a stratigraphic separation. However, the tortuosity of the dolomite occurrence may connect the Smith-Unruh 2 dolomite to the Edmonston location area somewhere along the Mississippi structural feature. The 1 Edmonston B was drilled and completed for about $145,000 in January 2000. Net pay in gas-bearing Mississippi dolomite stringers exceeds that present in Smith-Unruh 2. The Edmonston well tested 464 Mcfd on DST, with shut-in pressures of 1,573 psi. Based on experience, Oil Producers expects it to be a better well than the Smith-Unruh 2. After pipeline connection, the well is producing 900 Mcfd. With connection costs of about $25,000, total investment is $170,000. Well payout is expected within about 15 months. In this instance, Pangaea performed the geochemical sampling and interpretation with its funding. At commercial rates, costs would have been $8,000, adding about 5% to the total well cost. For that 5% incremental cost, the geochemical data provided confirmation that the Edmonston well, located near two dry holes, would indeed be prone to gas production. Additional Red Top Program data. The 1999 Red Top Program consisted of 30 gas-sieve, soil-vapor surveys, conducted in the Midcontinent region, prior to the drilling of 40-plus wells. The goals of the program were to collect a large body of gas-sieve data, develop models for interpretation of the data and to estimate the predictive success of the surveys as an exploration tool. The settings chosen for study were wildcat projects, infill drilling, waterfloods, underpressured reservoirs and gas projects. Eight models for interpretation were developed, and each of the 30 projects fit into at least one of the interpretative models. The gas-sieve method was found to be 85% predictive. That is, surface geochemical predictions, either producer or dry hole, correlated with later drilling results, whether a successful completion or a dry hole. Operators of the new discoveries and infill drill projects are continuing to drill additional locations and it appears that the 85% predictive success is holding. Overall predictive success for the gas projects has not been determined because five of the gas wells have not yet been drilled. Acknowledgments Pangaea thanks Oil Properties Inc. for contributing this project to the Red Top Program. It has proven beneficial to the development of the interpretation model for gas-sieve surveys. The authorsWilliam Shepherd has been a consulting geologist for Oil Producers Inc. of Kansas since the mid-1980s, and is heavily involved in prospect generation. Prior experience has been with Sterling Drilling and Zenith Drilling Corp. Mr. Shepherd holds a BS in geology from Kansas State University. J. Lynne Davison is president and senior geologist at Pangaea Geochemical Technologies in Wichita, Kansas. She previously served in the exploration department of Gear Petroleum, and has extensive experience in environmental investigations and remediations, as well as surface geochemical methods for oil and gas exploration. Ms. Davison holds a BS in natural sciences from Northwestern Oklahoma State University and an MS in geology from Wichita State University. |

|||||||||||||||