Microbial permeability profile modification extends life of oil field

Microbial permeability profile modification extends life of oil fieldJames O. Stephens, Hughes Eastern Corp., Jackson,

Miss.; and Lewis R. Brown and A. Alex Vadie, Mississippi State University,

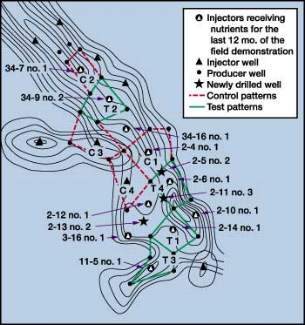

Starkville, Miss. Bottom line. Microbial permeability profile modification technology is being used to improve reservoir sweep and recovery in the North Blowhorn Creek Unit, Carter Sandstone waterflood in Alabama. Inorganic nutrients are being injected to stimulate growth of in situ microbes. This process diverts injection, thereby improving sweep efficiency. After five years, field life has been extended an additional five to 10 years or more. Field history. Hughes Eastern Corp.’s North Blowhorn Creek Unit (NBCU) is in Lamar County, Ala. Production is from Mississippian-age, Carter sandstone at a depth of about 2,300 ft. Discovered in 1979, the field was initially developed on 80-ac spacing. Waterflooding began in 1983. Production peaked at about 3,000 bopd in 1985, declining steadily to about 290 bopd in April 1994 – at the start of the project. Cumulative oil recovery at that time was about 5.3 million bbl, or 33% of the 16 million bbl original oil in place. Analysis indicated that ultimate recovery with conventional waterflooding would still leave 10 million bbl in the reservoir at abandonment, which was projected for early 2003 using $15 per bbl oil prices. The microbial permeability profile modification (MPPM) process involves adding nitrogen- and phosphorus-containing microbial nutrients to the injection water of a conventional waterflood operation. The nutrients stimulate growth of in situ microbes, not injected microbes, diverting water flow from more porous zones to unswept zones, increasing waterflood sweep efficiency. It is a reservoir process, not just treatment of individual wells. Since the nutrients are commonly used plant fertilizers and only microbes already present in the reservoir are involved, it is a very environmentally friendly process. Compared to other improved oil recovery processes, it is a relatively low cost method. Field demonstration test. Four injectors (patterns) were selected to receive microbial nutrients, and four other injectors (patterns) were selected as control injectors, Fig. 1. With this plan, production data from producing wells surrounding test injectors could be compared both with similar wells not influenced by nutrient injection and with their own historical data.

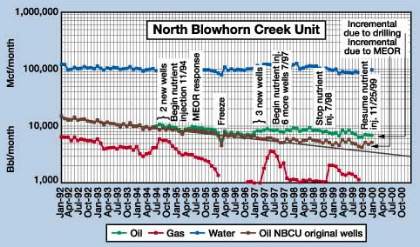

Two wells were drilled in late spring 1994 and cores obtained from one for flood testing. Based on coreflood experiments, Hughes made the decision to inject potassium nitrate (KNO3) and sodium dihydrogen phosphate (NaH2PO4) in two injectors (patterns 1 and 3), and KNO3, NaH2PO4 plus molasses in the remaining two injectors (patterns 2 and 4). Using a design injection rate of 500 bwpd, injection skids – with the capability to mix and pump 100–300 gal of water, containing 50–400 lb of chemicals per day, at a pressure of 1,200 psi – were placed at individual injectors. With the exception of molasses, the other nutrients were dry, so mixing capability was an important aspect of skid design. Nutrient injection began in all four test patterns between Nov. 21, 1994, and Feb. 27, 1995. Slightly different injection schemes were used. Test patterns 1 and 3 received 0.12% (w/v) of KNO3 on Mondays, and 0.034% (w/v) of NaH2PO4 on Wednesdays and Fridays. Test patterns 2 and 4 received 0.12% (w/v) of KNO3 on Mondays, 0.034% (w/v) of NaH2PO4 on Fridays, plus 0.12% (w/v) molasses on Wednesdays. In April 1996, these injection schemes were further tailored based on field performance data and additional coreflood testing. Evidences of in situ microbial growth. Microorganisms were shown to be present in cores from three wells drilled in the fall of 1996. There were considerably more microorganisms than observed in the 1994 (pre-nutrient) core. Fluid from all three cores also contained nitrate and phosphate ions, demonstrating that the nutrients were being widely distributed. Yet another indicator of microbial growth was a noticeable reduction in sulfide content in produced fluids that began about six months after nutrient injection started. Nitrates are known to inhibit sulfate-reducing bacteria activity. The produced fluids themselves never exhibited significant change in microbial populations, but that is not surprising, knowing that microbes prefer to grow attached to a substrata rather than be suspended in a medium. Production response. A pre-injection tracer study (April 1994 in 2-14 No. 1 injector) indicated that response should not occur sooner than seven months, and could take up to a year. Consistent with that data, Well 2-13 No. 1 showed production response, with a concurrent reduction in the rate of increase in the water-oil ratio (WOR), within seven months. At that time, no other wells had yet responded. By the end of 1996, about two years after nutrient injection began, eight of the 15 production wells in the test patterns showed a positive response. In contrast, two of the production wells in the control (non-nutrient) patterns had been abandoned due to uneconomical production, and five other wells continued their natural decline. One well in the control patterns had experienced increased production, attributed to increased injection support, not microbes. Thirty months after first nutrient injection, there were still no changes in production in the control patterns, while three more wells in the test patterns had shown evidence of response. Based on this overall positive indication, Hughes Eastern expanded the nutrient injection program, making 10 injectors total. One year after this expansion, 13 of 19 producers had responded positively, and two were considered possibly responding. Of the 13 responding wells, nine were confirmed as producing "new or bypassed" oil. The new-oil determination was based on gas chromatograph analysis of produced oil that indicated higher concentrations of lighter fractions as would be expected in bypassed oil. Higher gas production in some wells also pointed toward oil recovery from previously unswept areas. Incremental recovery and process economics. Overall production performance in NBCU is illustrated in Fig. 2. Decline curves show the flattening of decline in the original wells and the contribution from the new wells. During the recent period of very low oil prices, the operator halted nutrient injection. Although production held flat for a period of time, some drop-off is apparent. With improving economic conditions, injection was re-started in November 1999. Expectations are that production will be back up within a few months.

This project was part of a field demonstration under a DOE program, so it contained an R&D element that would not be encountered in commercial projects. Considering only nutrient costs and incremental costs (beyond what would normally be incurred) for operating, engineering, field equipment and field labor, the ultimate project cost is estimated at $658,000. This translates to $1.32 per barrel of incremental oil from the MPPM process – certainly one of the lowest for improved oil recovery operations.

Acknowledgment This project was supported in part by the U.S. DOE’s National Petroleum Technology Office as a Class I (fluvial-dominated deltaic) field demonstration project. Information for this case study was summarized from workshops presented in PTTC’s Appalachian and Texas regions and from SPE paper 59306 presented at SPE/DOE’s Improved Oil Recovery Symposium, April 2000, Tulsa, Okla. The authorsJ.O. "James" Stephens is vice president of Hughes Eastern Corp. in Jackson, Miss. His present responsibilities include a wide range of drilling, production and reservoir duties. He has prior experience with Arco and ANR Production Co. Mr. Stephens holds a BS in engineering from Mississippi State University, plus advanced study in law, and he is a registered professional engineer in Mississippi. Lewis R. Brown is a professor of microbiology in the Biological Sciences Department at Mississippi State University. Dr. Brown is considered an expert in bioremediation and environmental and petroleum microbiology, holding several patents and authoring over 100 articles. He holds a PhD in bacteriology from Louisiana State University. Alex Vadie is a professor of petroleum engineering in the Water Resources Research Institute at Mississippi State University. He has experience as a drilling engineer with NIOC and a consortium of American oil companies, as well as production and reservoir engineering experience. Mr. Vadie holds a PhD in petroleum engineering from the University of Texas at Austin and is a registered professional engineer in Texas. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)