Polymer gels improve waterflood sweep efficiency and oil recovery

Polymer gels improve waterflood sweep efficiency and oil recoveryGeorge V. Ricks, Belco Energy Corp., Dallas, Texas

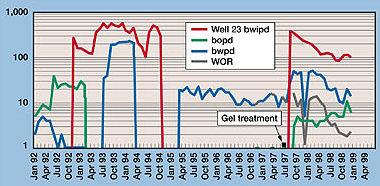

Bottom line. Polymer gel treatments in injection wells correct water channeling problems, recovering 15,000 to 25,000 bbl of incremental oil to date. The project paid out all its treatment costs in less than 10 months. Field characteristics. The 160-acre Hardwicke-University Unit is in the North McElroy field of the Permian basin in Upton County, Texas. The unit consists of eight active injection wells and nine active producing wells arranged in irregular patterns on 10-acre spacing. The unit produces from the San Andres / Grayburg dolomite formation at depths of 3,500 to 4,000 ft. Net reservoir thickness is 250 ft, and average porosity is 10%. The permeability contrast in the reservoir is high, since vugs and fractures are adjacent to much tighter matrix rock with an average permeability of 3.0 md. Oil gravity is 31.2°API, with a bottomhole temperature of 110°F. Original oil-in-place (OOIP) is estimated at 18 to 23 million bbl. Approximately 13% (2.9 million bbl) of OOIP had been recovered during primary operations, with an additional 150,000 bbl (less than 1% of OOIP) produced from secondary recovery, for a secondary-to-primary-recovery ratio of 0.05. Production problems. Sweep efficiency has been limited by water cycling through highly permeable rock from injection to producing wells. Wells injecting at high rate and low surface pressure were offset by wells producing at a high water:oil ratio (WOR). Since the highly permeable rock in the reservoir probably has been swept of secondary oil, continued cycling of water would not be effective in sweeping the tighter rock that contains the bulk of the secondary reserves. A specific water cycling problem had been identified between injection Well 23 and producing Well 6, which were located in the southwest corner of the unit. Well 6 originally had produced 20 to 30 bopd at a low water cut, Fig. 1. Starting in late 1992, water injection began in offset Well 23 at an initial rate of 400 to 500 bwpd.

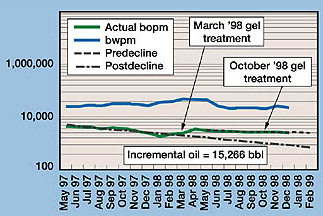

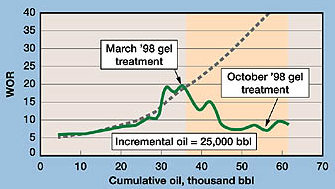

Within a few months, water production at offset Well 6 increased from less than five to more than 200 bwpd, while oil production stopped. Dye injected at Well 23 was detected 90 min later at Well 6, indicating that a primary channel (30 bbl in volume) connected the wells. An injection profile log at Well 23 also showed a small, focused channel. Subsequently, injection Well 23 was shut in during October 1994, but oil production was not regained at Well 6. Similar water cycling problems had been detected between most injection and producing wells within the field. Developing a treatment. Polymer gel technology was tested in 1997 to see if it would improve conformance and sweep efficiency. The goal was to divert drive fluids away from highly permeable, water-saturated zones toward the tighter, unswept rock intervals, allowing additional oil to be recovered at a lower WOR. Previous work applying gel technology suggests that it is most beneficial to fill the largest possible volume of the channels, without affecting the matrix or producing gel at the offsets. Building resistance to flow through highly permeable rock (and channels) helps divert drive fluids to tighter rock, raising injection pressure. The operator selected MARCIT1 gel technology since it was developed specifically for dealing with conformance problems in reservoirs exhibiting high permeability contrast, as would be expected in naturally fractured or vuggy formations. With this system, gels are created when dry acrylamide-polymer is mixed in water and crosslinked with chromium (III). Pilot test. The best candidates for injection-side gel treatments are wells that exhibit strong channeling to specific producing wells, as evidenced by high injection rates at pressures significantly below fracture pressure and water breakthrough at offset producing wells. There also should be significant mobile oil still in place that can be recovered. Based on these criteria, injection Well 23 was selected for treatment. Water injection was reinstated at Well 23 in July 1997 at a constant rate of 375 bwpd, with a 500-psi surface injection pressure. As anticipated, response from injection in Well 23 was immediate at offset Well 6; water production increased to more than 250 bwpd with no oil. A 50-bbl polymer solution was started as a tracer at injection Well 23 in August 1997; detection of the uncrosslinked polymer at offset producing wells would signal that the channels were nearly full. Next, 113 bbl of gelant (pre-gel solution) were placed into the reservoir, at which point polymer was detected in the produced fluids at offset wells. Gel injection was stopped, and injection Well 23 and offset producing wells were shut in for five days to allow the gel to form undisturbed. Results. Prior to treatment, the Hall Plot, a graphical tool for detecting injectivity changes, was relatively straight, showing stable pressure and no buildup. Following treatment, pressure increased to 900 psi and injection rate decreased as subsequent injection water was diverted into the tighter matrix rock. This 400-psi pressure increase has been maintained for 17 months. At Well 6, water production immediately decreased to 45 bwpd, and oil production was reestablished. As of December 1998, production at Well 6 was 6 bopd and 15 bwpd. This initial production increase is attributed to improved drawdown, resulting from decreased water production and subsequent lowering of the producing fluid level. Banking of new oil from previously unswept zones is normally slower and may not be noticeable for several months. Field-wide expansion. Based on positive results at injection Well 23, a gel treatment program was designed for all injection wells in the field. In March 1998, Well 23 was retreated with 500 bbl of polymer gel; four additional injection wells also were treated. The final three injection wells were treated in October 1998. Gel volumes pumped in March and October ranged from 500 to 2,000 bbl per well. Treatment effectiveness is being measured by monitoring injection wells with Hall Plots, and monitoring total field production with a rate-time graph and cumulative oil vs. WOR plot. Hall Plot data show that all treated injection wells increased and maintained injection pressures. Incremental oil recovered as a result of the polymer gel program is estimated from rate-time (Fig. 2) and cumulative oil vs. WOR (Fig. 3) data analysis.

Through December 1998, incremental oil recovery estimates range from 15,300 bbl (rate-time analysis) to 25,000 bbl (cumulative oil vs. WOR analysis). Incremental oil recovery has resulted from a combination of increased oil rate and decreased decline rate. Project payout was achieved in less than 10 months. Calculated costs per incremental barrel range from $5.29 to $8.66 per bbl of oil, depending on which estimate of incremental recovery to date is used. Any operating cost reductions resulting from decreased water-lifting costs are not reflected in the above numbers. However, it is projected that the per barrel incremental cost will ultimately decrease to around $1.00, which is the average for injection-side gel treatments performed to date. Conclusions. Polymer gel treatments, up to 2,000 bbl in size, using MARCIT gel technology reduced channeling problems in the North McElroy field. Oil production has increased, water production is down, and incremental oil (from 15,000 to 25,000 bbl) has already been recovered. Treatment costs paid out in less than 10 months. Early cost is in the $5.29 to $8.66 per incremental bbl range. Costs should decrease further as additional oil recovery from improved sweep is realized. Bibliography

The authorsGeorge V. Ricks, Jr., is an operations engineer with Belco Energy Corp. Since joining Belco in 1992, his primary responsibilities have been waterfloods in north and west Texas. Ricks, a member of SPE, received a BS in chemical engineering from the University of Oklahoma and an MBA from the University of Texas at Dallas. J. T. Portwood is southern region manager for TIORCO, Inc. His responsibilities include sales, project design and implementation and evaluation. He has 17 years of experience, most in applying improved oil recovery technology. Portwood, a member of SPE, received a BS in geology from the University of Texas at Austin. Copyright © 1999 World

Oil |

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)