What's happening in production

Lower-lifting costs can help ensure survivalWith the recent "oil glut" (real or not), and Wall Street’s "paper-traders" low oil prices reflecting 1999’s gloomy oil-patch business, survival relies on technology and good old "know-how" to make-a-buck these days. Service companies, inventors and all O&G concerns are constantly searching for better, more efficient ways to lift oil and gas to the surface and ensure a presence (survival), during the best and worst of times. Following are some examples of how technology is trying to cope with tough times in both deep water and on land. Increased production from low-volume "stripper" wells. Increased production and reduced electrical costs can help small producers. Toups Technology Licensing, Inc., (TTL) reports that its proven BORS (Balanced Oil Recovery System) Lift technology has been upgraded for more efficiency. In November 1998, the system went commercial.

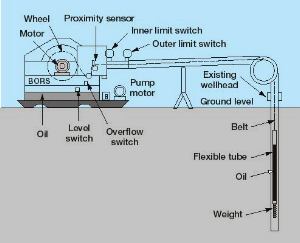

After nearly two decades of research and design, the lift system, invented in Oklahoma by TTL’s chief engineer, Gerold Allen, can increase oil production while reducing electricity costs, and it virtually eliminates the need for water separation / disposal. It is a unique, turnkey device that more economically produces oil from shallow, low-volume, gas or solution-gas drive stripper wells (10 bpd or less). Other well qualifications include 4-1/2-in. casing or larger and 2,500 ft or less oil perforation depth (a specialized logging run determines final acceptability on a well by well basis). By lifting oil with a flexible-tube canister and dumping it into a surface storage tank rather than pumping, the system eliminates conventional rods, tubing, downhole pumps or pumping units and related maintenance costs. Standing 5-ft tall and 7-ft long (with a 20-ft tube to the wellhead), it is capable of producing from a maximum fluid level of about 2,500 ft. The developers say that this BORS Lift system should not be confused with other bailing, swabbing or skimming methods (see "Mobile retrieval unit makes stripper wells economical," World Oil, March 1994). According to Mr. Allen, "The actual technology is down hole," and using a mathematical balance between the formation and produced fluids, a production "window" is calculated, and the system is then "fine tuned" to the individual well’s oil producing capabilities. Gary Mayfield, Tripledee Drilling, reports that before installing BORS Lift, production was about 4 bopd with 15- to 20-bpd water on average. After system installation, Tripledee is pulling 8–10 bopd with 2-bpd water — a 225% average increase across their three wells. Electric bills were also reduced. Deepwater state-of-the-art stimulation vessel unveiled. Stim Star was "Nine years in the making," and is the newest and largest vessel to join Halliburton’s GOM stimulation fleet. All of the vessels (including War Admiral and Man-O-War) are equipped to deliver the latest stimulation technology for maximum results. However, Stim Star expands the rough-sea, deepwater capabilities of the fleet and brings leading-edge capabilities to the wellsite with the largest proppant capacity of any vessel in the Gulf and virtually unlimited fluid capacity. Each GOM Stim-team member has received extensive training in all aspects of quality, safety and job performance. The fleet has never been cited for an environmental violation. Each vessel is equipped with a quality control lab, Big Inch manifold system and Coflexip hoses to help reduce rig-up / pressure-testing time, and HT-400 and Grizzly pumps. CO2 stimulation capabilities are provided with two 50-t, DOT-approved skid-mounted receivers. Additionally, each vessel is licensed to perform the Gidley CO2 stimulation technique. PC terminals (with built-in Minifrac analysis capability) and seating are provided for client use during stimulation treatments. Stim Star brings leading-edge capabilities to the wellsite with:

Coflexip is trademarked by Coflexip Stena Offshore. Additionally, Halliburton has registered

the Big Inch manifold system and trademarked the HT-400 and Grizzly pumps (and Minifrac

analysis system). Copyright © 1999 World

Oil |