Know what is in your wells: A practical way to manage well integrity in the digital age

Any type of well activity is associated with potential risk in the oil and gas industry. The industry works with hydrocarbons under pressure so, naturally, there is a risk to people, the environment and assets.

The adoption of reliable digital software to manage well risk is now an industry standard. More operators are utilizing digital technology to build a proactive and integrated well integrity approach. Furthermore, the benefits of having one common repository of standardized well barrier illustrations are reducing risk and delivering long-term value to the industry.

The application of digital well barrier illustrations that employ a two-barrier philosophy gives operators a starting point to safeguard their wells, preventing incidents from escalating into accidents. Moreover, engineers across all disciplines depend on a more reliable time-saving approach, beyond programs such as Excel, Visio and PowerPoint, to create well barrier illustrations.

Digital technology, such as the Wellbarrier* illustration tool (Fig. 1), offers engineers quicker, more effective and safer methods to define and safeguard their well barriers.

TWO-BARRIER PHILOSOPHY

Figuratively speaking, 90% of well integrity is about the technical well barriers, which have the capability and strength to contain pressure and hydrocarbons. The organizational and operational solutions are only the lubricants that help the process run smoothly.

The two-barrier philosophy focuses on mitigating risk in wells, with a primary barrier, backed by a secondary barrier. NORSOK, the Norwegian organization that sets standards for the offshore E&P sector, defines well barriers as envelopes of one or several dependent well barrier elements that prevent fluids or gases from flowing unintentionally from the formation, into another formation, or to surface.

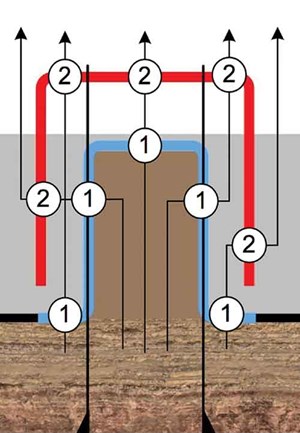

According to the two-barrier philosophy (Fig. 2), a primary barrier—the first object that prevents flow from a source—is needed to replace a caprock, which contains formation pressure, when it is removed. This barrier must function inside and outside of any casing that is run in the well.

A secondary barrier—the second object that prevents flow from a source—must be created to support the primary barrier. Independent from the primary barrier envelope, the secondary barrier envelope prevents flow from breach of the primary barrier envelope.

The main benefit of applying the two-barrier philosophy (the hat-over-hat arrangement) is that there is always protection whenever pressure escapes from the well. This provides a “belt and braces” confidence, giving us a reliable design to safeguard well activities and reduce risk. If two independent barriers are not available, it is even more important to understand the risk associated with each element.

WELL BARRIER SCHEMATICS

Several regulatory bodies and industry standards recommend that well barrier schematics (WBS) should be used to demonstrate that two independent barriers are in place.

NORSOK Standard D-010: Well integrity in drilling and well operations recommends that well barrier schematics are to be developed as a practical method to demonstrate and illustrate the presence of defined primary and secondary barriers in a well. Moreover, well barrier schematics shall be prepared for each well activity and operation.

The well barrier schematic is the backbone of the Wellbarrier illustration tool, a robust, cloud-based software solution for operating companies to safeguard their wells, with the objective of reducing risk and maintaining well integrity. This Schlumberger technology helps engineers visualize, communicate and document their wells.

The well barrier schematic clearly shows the well barrier definitions and can be applied to all phases of a well’s lifecycle, illustrating wells in operation. All illustrations can be presented in a sequence to show the step-by-step progress of the work in the well.

The Wellbarrier illustration tool produces well barrier schematics in a lean and user-friendly manner, helping engineers of all disciplines to create consistent well barrier illustrations in minutes instead of hours. It is also designed for users to know where to find the latest and most accurate well information in minimal time through a common repository. Moreover, there is an inherent quality assurance function through active use throughout the well’s lifecycle.

The software, which has been available since 2007, consists of the following functionalities:

- Well construction data—well data

- Well illustrations

- Well barrier schematics

- Well schematics, which show well curvature

- Formation, pore and fracture pressure curves

- Well control action diagrams

- Activity sequence diagrams

- Risk assessment and well ranking

- Completion diagrams and assembly drawings.

The tool helps operators to increase their productivity across all operations throughout a well’s lifecycle, while improving safety standards to protect their wells and minimize potential losses. It enables all engineers and decision-makers to see the same, clear picture, to better communicate and share a common understanding on managing well integrity.

More than 60,000 well barrier descriptions have been prepared, using the Wellbarrier illustration tool, which has evolved into the industry standard for well barrier drawings. To date, the Wellbarrier software has over 4,000 users in more than 45 countries, worldwide.

The adoption of this digital well barrier solution has helped more than 40 operators around the globe to increase their performance and progress their safety decision-making in well projects and operations.

CASE STUDY: MANAGING A LARGE WELL POPULATION

A major international operator used the well barrier schematic workflows in the Wellbarrier illustration tool to successfully manage a large well population. The well barrier principles provided a common approach to viewing well integrity, improving the consistency of managing well risks.

The operator was initially challenged with finding a common approach to evaluate the mechanical integrity of its wells. It adopted the Wellbarrier illustration tool, with the principles and schematics, to provide a comprehensive way to define and evaluate well integrity. It applied the software to manage its large and diverse well population—as well as its deepwater operations.

The company’s well integrity team took the following approach to prepare well barrier schematics for wells: well barrier training; data gathering; categorizing well groups and defining well barrier elements; well barrier schematic drawings; and verification.

The well barrier principles, with well barrier schematics, provided a comprehensive method to define and evaluate the wells’ mechanical integrity. The process was simple and readily applied to various well types throughout the entire well portfolio.

The three main benefits were: 1) The software helped users to quickly reflect the status of the well barrier envelope and assured them that any planned activities were in conformance and compliance with internal policy and local legislation; 2) By utilizing the Wellbarrier illustration tool, as opposed to multiple Excel formats, a change in the barrier envelope could be documented offshore within minutes; and 3) The software is easy to use and enabled the rapid drawing of proposed barrier definitions, which provided a better understanding of the well barrier and well integrity status among stakeholders.

This consistent approach improved the efficiency, accuracy and speed of the processes for evaluating wells and managing risk.

With its well portfolio now effectively managed and operating more efficiently than ever before, the operator concluded that understanding and applying well barrier principles should be considered a fundamental skill of every petroleum engineer.

RISK ASSESSMENT

In addition to the tool’s core functionalities, the Wellbarrier tool’s risk assessment functionality is an option that enables engineers to perform an objective risk assessment and ranking of their operating wells, Fig. 3. It employs the well barrier envelope definition as a basis for evaluation and is based on a standardized 5x5 risk tolerance matrix, with the primary objective of containment. When focusing on containment, other risks, such as the environment, assets and financial losses, are also accounted for.

It incorporates the well barrier illustrations, barrier element listings, and the two-barrier methodology as a fundamental and unique approach to risk assessment. The well barrier definition is used as a basis for a failure mode, effects and criticality analysis (FMECA) to assess the risk associated with pressure containment and the possible consequences. Risk assessment is, therefore, no longer driven by subjective assessment, but by a robust model.

This risk assessment compares all well types or individual wells with each other through a normalization algorithm; different wells and environmental conditions can be compared on equal terms to create an overall company overview. The risk assessment is pre-populated with failure modes for all relevant well barrier elements, with a preset failure probability that an administrator can adjust.

COMPLETION FUNCTIONALITY

The software’s latest update is a completion functionality, an option that gives engineers accuracy and clarity for well planning with consistent completion diagrams and assembly drawings. Engineers have full control to ensure that each well component is manufactured with precision and correct properties. It provides a high-level, easy overview with single-click access to any component detail.

Engineers receive all their information in one place—the information is consistent, stacked and presented on one page. When drilling a well and running a completion, engineers usually start with a finished product (what they want to do with the well) and then work backwards, step by step. The functionality provides a straightforward framework to create a consistent representation of all steps in the construction process. It helps operators nurture their wells, ensuring the best returns while maintaining well integrity.

INTEGRATION WITH THE DRILLPLAN SOLUTION

The Wellbarrier illustration tool has been integrated into the well design process in the DrillPlan coherent well construction planning solution from Schlumberger, a native application for the DELFI cognitive E&P environment that unites the E&P life cycle in the cloud. The integration of the Wellbarrier illustration tool with the DrillPlan solution enables operators to maximize results from their teams through seamless collaboration with all other domain teams, and access to all relevant data and science in a single, common system.

As well as connecting people and data, the DrillPlan solution connects leading software applications across exploration, development, drilling, production and midstream, and is delivered through a flexible and personalized SaaS subscription model. It is about sharing data in a secure environment, where there is trust and cooperation fueled by openness, which is critical for flexibility, to drive innovation in the industry.

WELL INTEGRITY VALUE CHAIN

Managing wells consists of several elements, with the well barrier illustrations as the core for several outputs in different contexts throughout a well’s lifecycle. The Wellbarrier tool is being enhanced further to provide a robust and holistic well integrity value chain to help operators reduce risk, Fig. 4.

This value chain basically starts with collecting data and knowing what is in the ground. The industry’s decision-makers may not always have the leisure of knowing everything, and stating “I don’t know” can also be a piece of information that needs to be taken into consideration.

Many of the well integrity challenges that operators face today are because of things that were done, or maybe were not done, in the past. Therefore, it is even more important that well integrity is managed correctly from the beginning. It is imperative that the industry maintains a strong focus on making available commonly shareable data that most people use, regardless of engineering discipline, from planning to P&A. Furthermore, the data must be readily and easily available for all the stakeholders to have a clear picture and a good understanding of their wells.

The value of well integrity management is in the technical knowledge and understanding of well barriers. Effective well integrity management, using digital well barrier illustrations and a two-barrier philosophy, assures long-term value to the industry.

*Mark of Schlumberger

- Digital transformation/Late-life optimization: Harnessing data-driven strategies for late-life optimization (March 2024)

- The reserves replacement dilemma: Can intelligent digital technologies fill the supply gap? (March 2024)

- Digital tool kit enhances real-time decision-making to improve drilling efficiency and performance (February 2024)

- Digital transformation: Digital twins help to make the invisible, visible in Indonesia’s energy industry (January 2024)

- Driving MPD adoption with performance-enhancing technologies (January 2024)

- Digital transformation: A breakthrough year for digitalization in the offshore sector (January 2024)