Riser project management— far beyond just rolling steel

In the past, as a manufacturer of OCTG tubular products for top-tensioned risers, Vallourec’s delivery ended when the pipe and connections pulled up to the dock. However, for the end-user, this was often far from the final step, with additional testing, coatings, accessories and marking for running still required. All extra products and processes required careful project management and technical expertise.

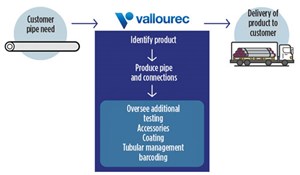

With a recent Gulf of Mexico (GOM) workover riser project, the Vallourec riser team took on the challenge of ensuring all these extras—including application of tubular management barcoding—were successfully executed, and final product was delivered on time, and ready for running. This article details those processes, challenges and steps to final successful delivery, Fig. 1.

THE PROBLEM

Workover risers qualified to API 17G and API 5C5 require both qualification work and additional production steps (as compared to API 5CT). This required careful planning, to ensure that the pipe and connection were qualified prior to production of the pipe and application of special coatings. The complex qualification, as well as coatings, lead to multiple interfaces for the end-user—the mill, R&D labs, OD coating manufacturers, ID coatings, often special post-mill inspections, accessory shops, and multiple stops and locations in-between. There is a web of contacts and “touch points” and line items—as simplified in Fig. 2. As the manufacturer and designer of the pipe and connection, there was a unique ability for Vallourec to incorporate the whole process under one project leader. As Fig. 3 shows, the project could go beyond the standard management of the R&D process and incorporate the full portfolio of services. This was especially important for high-pressure workover risers (WORs) and the associated services.

Full project management of all services was a departure from the past, where the model was to provide proprietary pipe and threaded premium connections, and simply advise on the remaining functions. In reviewing the requirements for API17G, it was found that the process didn’t stop at delivery of product. The requirements of API 17G went beyond just product. The process was altered to include all testing requirements. It was discovered that the need to bundle associated services, along with the product, and to provide project level management at every step, was crucial. It was proven that completing this task would make a difference in the end-user’s experience, relieving them of the multiple tasks on their own. In today’s competitive environment, providing a single-source solution is key. As deepwater projects in the GOM pick up, the need for bundling of services has become the key distinction in the success of projects.

A GOM CASE STUDY

To illustrate the overall project management, a recent development project in the GOM can be examined. A major oil company requested a 15,000-psi working pressure riser with high-temperature, fatigue, and make-and-break cycles. The product offered was a 7-in. x 0.85-in. VM110SS-D VAM TTR HW-NA. This product was developed by Vallourec’s riser team, customized to meet the specific needs of the project. It featured sour service grade material to meet the highest level of pressure and sour service performance. The connection, VAM TTR-HW NA, featured internal and external metal-to-metal seals designed specifically to meet the required loads. The extensive qualification work will not be contemplated here, but it was an important part of the overall project. Picking up along the manufacturing route, the following sections detail the project management.

Manufacturing of the pipe and connections

Once the final product was determined, the process was set in motion on how to go about providing the best solution for manufacturing. It started with determining the required amount of footage needed, and the timing in which the pipe and connections needed to be produced, as well as the ability to roll and heat-treat (most critical) sour service grades.

With many different potential product routes available, the final result offered was a multi-step manufacture, utilizing three mills—Mulheim Germany Piercing Mill, Aulnoye France Forge and final finishing in Dusseldorf Germany Plug Mill. This production route was required, due to the relatively small diameter and thick-wall sour service pipe requested by the end-user. This was a complex production route but, drawing on 20 years of experience in producing both pipe and connections for the riser market, this production route proved to be the best. With the plan in place to meet requirements, the pipe would need to be shipped from overseas to the U.S. in multiple batches. Coordinating the needs of U.S. customers with mills overseas introduced complexity, as well, and was part of the overall project management.

One of the key parts of managing the process was holding an onsite pre-production meeting with the mill in Germany, the riser team, and the end-user. This provided everyone involved with the opportunity to sit down, face-to-face, and lay out the details of the entire project. One of the most important things to consider with the project management role is clear communication across all channels. After carefully laying out all the details, which included manufacturing, not only the pipe and connections needed to meet the string length, but also enough material needed to manufacture accessories in the U.S., the production began.

Once pipe was in production in Germany, the next steps in the project timeline could begin. This included setting forth the plan for accessories manufacturing and pressure testing. Following the pre-production meeting, manufacturing began. Overall, manufacturing was very successful, and project management and communication with the end-user was frequent, to ensure small issues were overcome quickly, and high-quality pipe and couplings were sent on time.

Pressure testing: U.S.

The next phase of the project scope was pressure testing, Fig. 4. As per API 17G this pressure testing had to be performed at 22,500 psi and follow a cycle of pressurize, hold and re-pressurize. This pressure was slightly outside the mill capacity, and cycle testing inline at a manufacturing facility was difficult, due to bottlenecking at the facility.

Testing then had to take place in a separate process step. This included developing a relationship with a local testing company in the U.S. and determining that the equipment available would meet the stringent needs of API17G. Vallourec chose to work with Stress Engineering Services (SES). Once a provider was settled on, exact details of the pressure testing were gone over at great length to meet the end-user’s needs. Not only was there a need to source a local supplier to complete the pressure testing, but the need also arose to order specific test fixtures for the process, with the propriety connections on them. These specific test fixtures were designed, tested and manufactured in France. This was due to the special pressure fixture feature: hold pressure without engaging the connection’s metal-to-metal seals and risk handling damage.

After multiple technical discussions to ensure that the pressure fixtures met the testing facility fittings and safety requirements, the test fixtures were on order, and pressure testing could then be scheduled. One challenge that arose during this portion of the project was dealing with a large quantity of Range Three pipe. Logistics to efficiently test, in a cost-effective way, were difficult. As with any project, keeping a close eye on the process and schedule is very important, as problems can arise and dates can slip easily. Having worked with the pressure testing company in the past, the relationship helped keep things moving along on schedule and, most importantly, within budget.

Accessories manufacturing

The next part of the process was to find an accessory manufacturer that not only could make the parts to specification but could also meet the timing needs involved. For manufacturing accessories in the U.S., the Vallourec tube alloy group met the challenge. As previously stated, this part of the process began all the way back to the beginning, with careful planning of the need for extra material and the timing involved. This was solved by working with the mill in Germany, to make sure that enough extra material was processed and shipped early (before the threaded and coupled pipe), in time to meet the required dates. Once material arrived in the U.S., another pre-production meeting was held, with an initial meeting of all involved parties to go over the manufacturing plan and schedule. Typically, in the past, this process was part of the end-user’s scope; however, this was managed as part of the complete package offering.

As all the accessories were being manufactured locally in the U.S., operations (threading) were run in parallel with the mill in Germany. Taking advantage of the parallel operations, both entities were able to hold meetings on best practices and thus solve issues as they arose, again providing a single source solution to producing the premium connections. This was especially important, as the thread represented a new size and was manufactured on multiple accessories of various functions, materials and diameters.

Crossover M&B testing

Along with pipe being produced in Germany and accessories being manufactured in the U.S., multiple grades on the accessories were included as part of the full-string design. To ensure performance between the grades—crossover assembly and disassembly cycles or “make and break” (M&B) testing was performed for this part of the project—

another service provider, VAM USA R&D lab, was introduced to the process after careful consideration of the project needs.

The scope of this part of the project included not only the riser team but also the EPC company that was working with the customer on the manufacturing of the crossovers. Coordination and careful planning with all three companies ensured that M&B testing was completed successfully.

Midway point

Up to this point in the project, multiple steps were completed, as outlined below, and the final phase of the project was getting ready to commence:

- Plain end pipe and coupling material had been produced and shipped to the U.S.

- Pipe and connections had been produced in Germany and shipped to the U.S.

- Test fixtures were manufactured in France and shipped to the U.S.

- Accessory manufacturing had started

- Pressure testing was underway, utilizing pipe from Germany and test fixtures from France.

Once pipes and accessories completed pressure testing preparations for the final scope of the project, which included external pipe coatings and tubular management, barcoding could start. In the beginning, the end-user had required a typical OD coating, thermal spray aluminum; however, due to changes in needs, a change was made mid-project. Due to storage and maintenance requirements, a new coating was specified (painted coating). This required working with the new company to get qualified and set up for this project. As with any new supplier or product, a careful vetting is required for safety, cost and schedule. This was difficult to do while maintaining delivery schedule, but it highlighted the value of a single project manager that could react quickly to the change and mobilize resources.

Coating

The new supplier had worked with multiple tubular products, but never with a premium threaded and coupled pipe for the external coating, Fig. 5. To ensure a successful end result, trainings were held, and the process was followed by utilizing VAM Field Service personnel. Careful consideration was given during every step in the process, utilizing the Field Service group and quality engineers from multiple sites. In addition to external pipe coating, a new process was rolled out, which included the newest service option of tubular barcoding.

Tubular management barcoding

The option for the end-user to have specific traceability on all product delivered was the final step in the project. This service option includes the application of a unique barcoding system that is applied to the OD of all pipes in multiple locations. The barcode allows tracking to take place while running, and the data set associated with each pipe and connection. The end-user is then able to enjoy faster running, along with the tracking of where each individual joint is in the string, the individual length and the ability to track depth reached.

As this was the first time being utilized in the U.S., trial running commenced immediately following coating. This involved training personnel on the new process and equipment and running multiple trials before applying the barcoding and setting up the system. After successful barcoding application was completed, the product was run offshore, utilizing this tracking system.

CONCLUSION

The result was a successfully delivered product that met all of the customer’s requirements on time. One of the key learnings is that, to be able to handle a multi-faceted project such as this, careful project management needs to be implemented by an overall project manager, who can oversee the process from order to delivery. It provides the necessary oversight to ensure that quality products are delivered on time, and within budget. In terms of project management, this latest GOM project proved to be quite challenging, as there were multiple moving parts and entities to keep a close eye on. In the end, however, product was delivered successfully and showed that offering a single-source solution and project management can be very valuable in today’s market. WO

- Advancing offshore decarbonization through electrification of FPSOs (March 2024)

- What's new in production (February 2024)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- U.S. operators reduce activity as crude prices plunge (February 2024)

- U.S. producing gas wells increase despite low prices (February 2024)

- U.S. drilling: More of the same expected (February 2024)