Reliable sand detection helps to optimize separator efficiency, prevent costly shutdowns

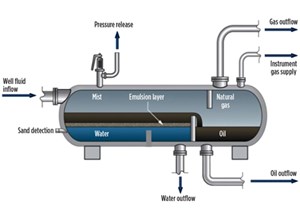

The separation of oil, gas, water and sand/solids, typically performed by a separator, is a crucial step in the production process. This separation enables hydrocarbon recovery to be maximized and allows the flow or production rate of the individual component streams to be measured. This provides essential information about the quantity of fluids produced from each well in the field.

A major challenge for operators is to prevent excessive sand build-up, which can clog inlets and the separator’s sand drain pot. Sand build-up limits the separator’s valuable capacity, and if not monitored and removed, can lead to a shutdown while a cleaning-out process takes place, which could be extremely costly. Reliable detection of the build-up of sand deposits in a separator is, therefore, vital.

SEPARATORS

Separators are used for periodic well testing (as a test separator) or continuous production measurement (as a production separator). Two-, three- and four-phase versions are deployed—the phases referring to the number of streams leaving the separator. Two-phase separators are used for the separation of the well stream into gas and liquids, while three-phase separators are used to separate gas, oil and water, Fig. 1. A four-phase solution separates the sand. When well streams also contain sand and other solid particles, separators incorporate internal devices to collect and dispose of this material.

Separators rely on gravity to segregate the different components of the well stream. After the well fluid has entered the vessel, the gas quickly separates from the liquid, because it weighs far less than either oil or water. The gas is then routed up into a separate chamber and exits the separator through an outflow pipe to a gas processing system. The liquid, meanwhile, is routed to the bottom of the vessel, where the oil forms a layer on top of the water, because it is less dense. This oil layer then spills over a weir into the vessel’s oil chamber, and the oil and water each exit the separator to their respective processing systems via different outflow pipes.

SAND CONTROL AND BUILD-UP

If the reservoir or type of production application produces sand, it will start to accumulate in a lower chamber of the separator. Protective sand control measures, such as expandable sand screens and gravel packing, are a common requirement for limiting the amount of sand that reaches the separator. However, implementing such measures is not a straightforward process. First, well pads are often geologically different, even if they are relatively close to each other. Some wells produce a lot of sand and some very little, making it difficult to predict the level of sand control required. Each well pad may need a different sand control technology, which adds complexity to operations. Also, the installation of these protective measures requires a lot of time and skilled resources.

Even if these measures are working correctly, some sand will still accumulate in the separator over a long period. However, a failure in sand control will accelerate the sand build-up in the separator, which could clog the sand drain pot. Excessive sand in the separator encourages the formation of unwanted emulsions between oil and water, limits capacity by taking up valuable volume, and leads to a reduction in oil flowrate. Also, when the sand build-up in the separator gets to a certain level, it can get pumped out with the water, which can lead to devices downstream of the separator—such as pumps, valves and flowmeters—suffering damage through blocking, abrasion or erosion.

Should the sand build-up become excessive, there would need to be a shutdown, causing an expensive loss of production, and a call-out for removal of the sand blocking the outlet, which would be both time-consuming and extremely costly. Awareness of sand build-up is, therefore, crucial in maximizing separator and production efficiency, and preventing devices from suffering costly damage.

MONITORING SAND BUILD-UP

Most operators do not have a regular inspection routine, and separators are typically run until a problem occurs. Technology that provides detection and monitoring of sand build-up, and prevents problems from occurring is therefore of significant benefit. Nucleonic technology—in which a gamma source emits radiation toward a detector at the other side of the vessel—has been used, but it has several drawbacks. These include the levels of risk and complexity; the need for yearly validation requirements; the necessity to comply with local laws; and high cost of ownership. This is driving operators to find alternative solutions that are reliable and safe, and less complex and costly.

Such an alternative is now provided by the latest vibrating fork level detectors (Fig. 2) from Emerson Automation Solutions, which provide unique functionality that enables constant monitoring of the build-up of sand in a separator, thereby eliminating the risk of an unplanned shutdown, if the deposits exceed a critical level. These devices, which are used traditionally to monitor air-to-liquid interface (liquid point level), operate by using the concept of a tuning fork. Two fork tines are immersed into the vessel, an internal piezo-electric crystal oscillates the forks at their natural frequency, and changes to this frequency are monitored continuously.

The frequency varies, depending on the medium in which the prongs are immersed—the denser the medium, the lower the frequency will be. This principle also enables the device to be used for monitoring liquid-to-sand interface via a special “sand switch” function, which makes it an ideal choice for separator applications. The data from the device can be transmitted to a control room, enabling the sand build-up to be monitored remotely.

The device is very simple to configure for sand detection, with four sensitivity settings for least, medium, high or most compacted sand, since the properties vary across different well pads. As well as detecting the build-up of sand, these devices also can be used in a control system to automate the chamber’s clean-out cycle. This eliminates the need for this process to be performed manually.

These vibrating fork level detectors have several other benefits, including being compact, lightweight and easy to install. The shape of the forks ensures that any sticky or viscous material is less likely to attach itself to the device and instead drains away quickly, making the forks ideal for separator applications. Also, there are no moving parts that can freeze or get stuck, which increases device reliability.

Using HART communications, these devices deliver the benefits of advanced smart diagnostics, providing greater insight into the condition of the device, and supporting predictive maintenance practices by identifying potential problems before they become serious.

Furthermore, by monitoring fork frequency, it is also possible to detect media gradually building up on the tines. While vibrating fork technology has good resistance to light-to-moderate build-up, growing deposits can lead to an incorrect wet signal, if left unchecked, especially if the forks become bridged. The ability to monitor media buildup on level instrumentation can be particularly useful in oil and gas production, due to the presence of coating materials, such as paraffin wax. All diagnostic information can be accessed, either directly or from the control room. The latter option eliminates the need for field trips.

EFFECTIVE SEDIMENT BUILD-UP DETECTION

An oil and gas company in Sichuan, China, is using a Rosemount 2140 Vibrating Fork Level Detector to detect sediment deposits in an oil, gas and water separator. As part of the shale gas extraction process, a four-phase separator is used for effectively de-sanding the mixture of oil, gas and water. The sand level within the separator must be monitored and alarmed to avoid the problems of pipeline corrosion and pump abrasion that can be caused by a high sand content.

To achieve this, Emerson’s Rosemount 2140 has been installed and is providing reliable detection of sediment build-up. Qualification was straightforward, with the device meeting material certification requirements for its wetted parts; a necessary requirement since units are installed in H2S-containing environments. Data from the vibrating fork are transmitted via HART communications and used to alarm when sediment deposits reach a critical level. Clean-out can be scheduled proactively.

SUMMARY

Separators play a fundamental role in oil and gas production. Excess build-up of sand within a separator is undesirable, as it can clog the sand drain pot, therefore limiting the separator’s capacity, Figs. 3a and 3b. This potentially causes devices downstream of the separator to be damaged by sand that is pumped out with the water. When built-up sand needs to be cleaned out manually from the separator’s bottom chamber, the process requires production to be stopped, which can prove very costly.

With most operators not having a regular inspection routine, it is crucial that sand is reliably monitored, so that excessive build-up can be prevented. Nucleonic technology can perform this task, but has several disadvantages compared to the latest vibrating fork level detectors. The newest generation of devices now available features a unique liquid-to-sand interface option, which enables reliable detection of build-up, and the ability to optimize or automate clean-out cycles, thereby increasing worker safety and production efficiency. ![]()

- Shale technology: Bayesian variable pressure decline-curve analysis for shale gas wells (March 2024)

- What's new in production (February 2024)

- U.S. operators reduce activity as crude prices plunge (February 2024)

- U.S. producing gas wells increase despite low prices (February 2024)

- U.S. drilling: More of the same expected (February 2024)

- U.S. oil and natural gas production hits record highs (February 2024)