Protecting offshore assets from the risks posed by vessels

Offshore operators have had limited options for protecting their assets from the risks posed by vessels, either supporting them or operating nearby. Not only must they avoid incidents to maximize uptime, they also must protect personnel from harm and keep them focused on the most productive tasks. This has been difficult to do with earlier mitigation strategies, including setting radar “guard ring” range limits to notify watch-standers, when approaching vessels are becoming a threat. The alternative of sending an aircraft to periodically survey critical assets does nothing to prevent an incident. For those operators who have multiple offshore assets, the challenge is even more difficult and complex.

There is now a data-driven approach to solving this challenge that leverages Automatic Identification System (AIS) information. For the past 10 years, this system has been used to monitor vessels for a broad range of logistical and safety reasons, by most major oil companies. These data are combined with radar and other location-specific, real-time input from the operator’s asset sites, and used to create a single, shared view of all vessel activity that might pose infrastructure risks.

A number of key elements are required for successfully launching an AIS-based, risk-mitigation program. First, operators must audit their current risk monitoring, measurement and mitigation process, conduct a site-specific assessment of each asset’s risk profile, and make sure they have access to all necessary data for each defined risk.

The next requirement is a monitoring platform that can combine all of these data sources into a shared display and issue customized alerts. They also need a well-defined set of procedures for assessing and mitigating risk. In addition, staff should be trained to assess and validate risks, configure alerts and initiate the appropriate mitigation measures. It is particularly important to clearly define risk assessment and mitigation procedures. A web-based, vessel-tracking platform is of tremendous value here. By providing analytical reporting tools and access to historical data, this platform will enable operators to configure and issue automated alerts for each asset. The parameters for these alerts should be based on each asset’s unique risk profile, so that alerts are only triggered when agreed-upon criteria are met. These criteria might include the type of vessel, the speed it has reached, and whether it has reached the closest allowed point of approach under a given set of weather conditions.

Alerting is critically important to get right—and especially the process of filtering out false alarms—so that offshore teams must only deal with relevant alerts. After today’s tools ingest all data from AIS transmitters, radar targets and other sensors to deliver a comprehensive view of each vessel, point of interest or user-defined zone, they employ sophisticated software to ensure that they are only sending alerts about vessels that are becoming threats to identified assets.

Not all organizations can support these types of activities, and the best approach is often to use professional, third-party services located shore-side. One offshore operator that adopted this strategy had already been employing AIS tools for vessel monitoring, and wanted to extend its use to manage risks to a new Gulf Coast pipeline, located in an area of high vessel traffic. The operator did not have a risk-mitigation process in place, and its staff was already fully engaged with other activities. Needless to say, they could not manage these new, significantly higher volumes of risk-management data, nor were staff members trained to validate and respond to triggered alerts. The company began outsourcing AIS-based risk monitoring and evaluation to a professional, third-party service, as a first line of defense, to ensure that their attention was only on critical and actionable issues.

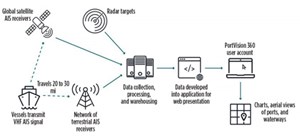

Using this approach, all live data feeds are monitored around the clock, at a central, shore-side location, by teams that have the specialized expertise to evaluate and validate alerts, make initial risk assessments, and communicate those risks that need immediate action, Fig. 1. This was particularly important for one operator that manages remote assets in the Gulf of Mexico and the Caribbean. The company consolidated all of its risk-mitigation activities for these assets at an onshore location. Here, a dedicated team was responsible for alerting offshore crews, at least one hour before any vessel reached a point where it posed a threat that required mitigation. This greatly improved the organization’s awareness of approaching vessel risks, while enabling much earlier initiation of risk mitigation measures. As one of the most valuable examples of its effectiveness, the shore-side team identified a shipping vessel heading toward its offshore field, more than three hours ahead of its likely arrival. Offshore crews had ample time to redirect the inbound vessel, before it became a more serious threat to multiple, high-value assets.

Another benefit of consolidating risk-mitigation activities shore-side, with a dedicated team, is that it standardizes training and procedures across all of the organization’s platforms. Operators know they are applying risk-management activities, consistently, across all assets. It also enables such new capabilities—as centralized remote watch-standing—across all of an organization’s assets, anywhere in the world. These teams can also identify trends, analyze new vulnerabilities and generate better ways to mitigate risk. Once best practices are established for one set of assets, organizations can use them with any type of critical infrastructure.

Deploying a centralized monitoring platform also significantly increases the value of hardware deployed to the individual assets. It provides overlapping regional coverage to help prevent blind spots.

System integrity can be improved further by using the centralized, watch-standing team to oversee the health of the hardware and network. The team can be responsible for creating system maps and network “health” dashboards that monitor failure points and issue alerts when necessary.

BEST PRACTICES

Organizations must first understand how vessels are interacting with their assets. Today’s vessel-tracking platforms facilitate this by combining AIS data with inputs from radar, cameras, weather monitors, VHF communications and other onsite hardware, into a collaborative web-based tool. They also provide up to five years of historical vessel-position data that can be used to model how vessels have interacted with the organization’s assets, Fig. 2. Additional location-specific, real-time data from the asset sites also can be included to provide a shared, operational view, across multiple assets, in a common region. This gives operators a clear, comprehensive picture of how vessels are interacting with each asset and posing the risk of a potential impact.

Radar is a particularly important input, allowing operators to see vessels, even when they are not transmitting AIS signals. Another benefit of radar data is that they provide redundancy and are more secure than AIS, since they cannot be turned off or modified to provide a false picture of activities or positions. Different types of radar are needed for different situations. The radar requirements for the risk of impacts from fast-approaching vessels, for instance, are very different than those for slow-moving vessels operating in adjacent shipping lanes. Another hardware option is to deploy an AIS Aid to Navigation (ATON), and program it to proactively send a safety message directly to the wheelhouse of an approaching vessel. This can deliver an even faster way to warn a vessel’s crew that it is approaching a fixed structure. A comprehensive data-collection network is shown in Fig. 3.

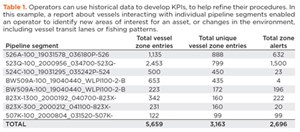

Operators also should use their risk-management team and tools to actively collaborate with vessel operators on collision avoidance. Having access to analytical reporting, historical vessel position data, and triggered alerts enables operators to improve emergency responses, while facilitating the ongoing measurement of key performance indicators (KPIs), so they can continuously improve mitigation procedures. One KPI finding might be that certain vessels repeatedly trigger alerts or fail to interact with watch teams, Table 1. The operator can target these vessels specifically for outreach and educate them about safe passing distances. They can also navigate around submerged hazards, as an additional preventive measure.

Today’s centralized, asset-monitoring and risk-management platforms provide a new, data-driven way to mitigate the risk to offshore assets posed by vessels. They incorporate all necessary data inputs into a web-based tool that can issue customized alerts. Also, they facilitate ongoing KPI-based performance improvement, as well as active collaboration with vessel operators on collision avoidance. Taking the additional step of outsourcing some, or all, of the risk monitoring and mitigation process to a shore-side, third-party provider offers the potential to cut costs, as compared to deploying individual teams across multiple assets. It also enables organizations to standardize procedures across all locations worldwide, while ensuring that specially trained professionals are dedicated to the task, and can provide consistent performance and results across the infrastructure.

Aaron Kline has over 15 years of business development and project management experience, optimizing delivery of project cargo and facilitating marine logistics along the Gulf Coast. After serving in the U.S. Navy as a submarine officer, Mr. Kline began his career at FMC Technologies and then joined Chevron as an operational excellence engineer. He then joined FTO Services as a business development manager for subsea, before joining Signet Maritime, a marine logistics company. Mr. Kline also has completed over 20 years in the U.S. Navy Reserves, as a submarine officer. He graduated from the United States Naval Academy and is also a distinguished graduate of the University of Houston with an executive MBA. ![]()

- Advancing offshore decarbonization through electrification of FPSOs (March 2024)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- U.S. producing gas wells increase despite low prices (February 2024)

- U.S. drilling: More of the same expected (February 2024)

- Driving MPD adoption with performance-enhancing technologies (January 2024)

- Digital transformation: A breakthrough year for digitalization in the offshore sector (January 2024)