Roughnecks to digit heads: The rise of the digital oil company

The term, oil field, conjures up images of men covered from head to toe in crude. But that was a long time ago, in an oil field far, far away. Today, most of the world’s oil comes from places that these workers wouldn’t have known, extracted through techniques unimaginable decades ago.

The oil and gas industry is now in a unique phase of its history. Today, it is much more like a manufacturing business. Oil and natural gas are produced in what amounts to an assembly line. Around the world, companies are drilling holes more reliably through the most productive parts of the formation and, most importantly, drilling faster with fewer mistakes and less down-time. Productivity gains have been seen across the spectrum, but nowhere as dramatic as in shale.

Unconventional oil and gas have seen productivity grow by leaps and bounds since the industry first began producing natural gas from shale rock more than a decade ago. Now, shales are identified, and fleets of rigs, pump trucks, sand trucks, water and people are deployed. Wells are drilled and completed, and the work moves on to the next drilling pad.

So far, the efficiency gains that we’ve seen have resulted from process refinement and “practice makes perfect.” The more wells we drill, the more we learn about where the oil and gas reside, how the equipment works, where we lose time, when we over- or under-use material and make mistakes. This happens with, or without, the aid of data analysis or automation. Bringing digitalization into the mix, both in the field and in the office, is the next step in the industry’s transformation.

Competition and the need to reduce costs always will exist in the industry. But the need to reduce cycle time and drive efficiency throughout the value chain has never been more critical. The transition from a natural resource (scarcity) paradigm to a manufacturing paradigm creates obvious analogies and opportunities. When shale oil hit the market, and OPEC defended its market share, the ensuing price collapse made it all the more urgent to take advantage of those opportunities.

The industry is under pressure to cut costs. Up until now, most of the improvement in well economics has come from two things. First, capital spending has been concentrated on the most productive resources. Second, operators have been aggressive (and successful) in asking service companies to reduce pricing. Service companies have been willing to do this, to keep equipment busy and hold market share, but eventually they’ll have to start making some money, too. The way to get costs down is to reduce the amount of time that it takes to get people, equipment and material to the wellsite, get them there at the same time so that nothing is left waiting around, and reduce the amount of time that it takes to drill and complete a well.

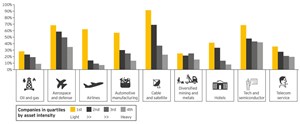

As in manufacturing, cost reductions will come from speeding up processes, cutting out downtime, reducing the use of materials and eliminating mistakes. The oil and gas company of the future will be no exception to this, and technology now offers several tools and techniques that are gaining traction in moving digitalization from the wellbore to the back office (Fig. 1), including the industrial internet of things (IIoT), analytics, big data and robotic process automation (RPA)—also known as digital labor. Digital labor has been a popular entry point for bringing the latest digital technologies into the office. It can provide a big return on investment in a relatively short time, and it frees employees from mundane processes, enabling them to focus on other valuable tasks.

THE OPPORTUNITY

Below-ground activities, such as drilling or completing a well, have enjoyed a digital revolution that started decades ago. Many of these activities are now automated and have been for quite some time. Steering a drill bit into the most productive rocks is a tricky business, particularly when the well is thousands of feet under water. That process is already driven largely by computer software, using advanced analysis of data gathered by sophisticated instruments. Likewise, shale wells are increasingly complicated. Applying the right mix of water, sand and chemicals, under just the right pressure, is already driven largely by computer software, using advanced analysis of data gathered by sophisticated instruments.

Above ground is another matter. Achieving surface efficiency has (to date) been largely the work of employees collecting orders and making decisions to dispatch equipment, workers and material to the wellhead. These decisions are not simple. There are multiple trade-offs involving cost, quality, availability and timing. When times are good, demand and supply are closely balanced, and there will be occasions when demand exceeds supply. This requires supply chain analysts to make judgments about what to send where, and when, based on which clients have the most favorable pricing and the most important long-term relationships. Suffice it to say, there are many opportunities to make the wrong decision and cost yourself or the customer money. In other words, there are opportunities to introduce computer-assisted decision-making and robotics.

THE APPLICATION

A million decisions are made in the oil field every day. With the right data, analytics, algorithms, and control technologies, those decisions can be made and executed by computers. This allows people’s time and attention to be directed toward higher-value tasks, such as creating and marketing new products.

The benefits of these technologies are greatest in operational and logistical processes, where there are handoffs, and the opportunity for lost time and mistakes. Integrating the process of well planning with the process of ordering and dispatching of pumping equipment, operators, water and sand to the wellsite is an obvious example. Processing data regarding the location of equipment and supplies, identifying risks to project schedules, and then making adjustments is another. A fully digital and mobile supply chain, driven by RPA and enabled by the internet of things (IoT), sensors and advance analytics, can reduce cycle time and drive efficiency throughout the value chain.

Another potential source of value for a digitally enabled supply chain combining RPA, analytics and mobility is in the pricing of oilfield services. Traditionally, pricing in the oil field has been driven by anecdotes, rather than hard data. Jobs are usually priced by account managers (with approval), based on what it takes to “get the work.” Pricing is a situation, where doing the right thing at the wellhead might not be the right answer for the company, and a data-driven process could be the answer.

There are multiple moving parts that a single person, without the benefit of analytics, cannot track. The true cost of serving the customer involves factors (such as material scarcity or the pricing that competing jobs might be getting) that an account representative doesn’t have visibility into. For instance, an individual account representative doesn’t have the visibility into competitor behavior that the company, as a whole, can have. Computers are generally better at solving complex optimization problems than people.

No one is suggesting these decisions should be centralized. Computer models and analytics are an aid to judgment, not a substitute for it. Airlines (the ultimate capacity-based business) have led the way on pricing science and have defined best practice in the field of “yield management,” Fig. 2. The oil and gas industry would benefit from looking hard at their processes and imitating what works best.

THE BUY-IN

These applications of technology can be adopted; the question is whether they will be. The success of any strategy depends on someone making a decision and having the will to carry it through. Surprisingly—or perhaps not—most of the barriers to the effective use of robotics and analytics are cultural. For data analytics and automation to work, everyone within an organization has to be onboard.

Data quality is an essential first step in the journey to a data-driven business. You’ll only get that if the people who do the work are capturing the right numbers, and the numbers are warehoused and organized in a way that enhances and speeds up decision-making. This will take time to set up and get right. Companies that have an innate sense of urgency, and are focused on rapid execution and speed to market (a good thing), can have a cultural bias against using time today to capture data and distill it into information. Data analytics can, and should, be presented to the people on the front lines as a vehicle for speeding up the next cycle and making the business more competitive.

There will then be a learning period, where people absorb more sophisticated techniques and begin to understand their benefits. This is particularly true, when the end game is the replacement of human decision-makers with robotics. It is essential to distill all of this down to its essence, highlighting the operational and commercial benefits, defining specific things that you need everyone to do, and generally aligning the interests of employees and the company around data analytics.

Some employees will be skeptical. Pilot projects or targeted introductions that create quick wins are an essential element of a buy-in process. Do something manageable, high-value, low-risk and low-disruption. Demonstrate value, gain experience, and get the team onboard before moving on to something bigger and more game-changing.

THE PILLARS OF SUCCESS

A digital culture stands on four pillars: a commitment to digital management; acceptance of the need to hire and promote people who might be different from those who made you successful; a focus on execution; and a willingness to act on what we learn from data analytics.

Commitment to an automated workforce and a data-driven approach. The oil and gas business has a lot of people who “go with their gut,” and a lot of them are successful. First-mover advantage is a real thing, and it’s faster to act on an impression than it is to stop and analyze the situation. That approach can create a lot of value, but it also creates a lot of risk. The culture needs to accept the fact that the numbers don’t lie, and computers can do these jobs. The critical insight here is that competition is out there, and eventually there will be a lot of first movers; moving first, but in a direction subtly different from the one that instincts might take us in, is the real advantage.

Be sensitive to concerns that people have about introducing analytics and process automation. Paralysis by analysis can happen. The perception (real or imaginary) that analytics are slowing down sales or operations is a deal-killer. A good rule-of-thumb for any kind of organizational change is that everyone needs to be at least as well off as they were before everything started. Time invested in process design, in addition to technical excellence, is time well spent. Algorithmic processes need to be designed in a way that makes existing processes at least as fast as they were before, just better informed. Quality execution matters, when it comes to acceptance. The quality of the underlying data, and the quality of the analysis, needs to be beyond question.

Acknowledgement of the changing workforce. Data-driven companies will need additional skill sets, in addition to those that have made oil companies successful in the past. Initially, geology and petroleum engineering were the value-drivers in the oil field. Logistics, supply chain management and process engineering have become important enablers, even differentiators, as the business has become more like manufacturing. As that happened, the skill sets were added. The next wave, process automation, will require yet another transformation and expansion of the workforce. Computer programming and data science may drive the business. Below ground, those skills have been integrated successfully. In the back office, the oil business should take a page from the book of finance, where the masters of the universe have learned to live and work side-by-side with mathematicians, statisticians, computer programmers and scientists.

Focus on execution. Knowing what to do is one thing. Knowing how to do it, and the order to do it in, is another. Replacing processes that are proven, but may be a little inefficient with robotic processes, can be a risky proposition. Fortunately, there are ways to manage those risks.

The first wave of technology implementations around enterprise resource planning (ERP) systems gave the industry a rough outline of a path forward for process automation, and the next wave of digital transformation. Before starting out on any transformation journey, executives must answer key questions. What will define success? There’s no substitute for an achievable set of goals. These may be financial objectives, operational objectives or a combination of both.

Understand the process thoroughly. Before transformation begins, make sure to understand how processes work now. When it comes to process design, what are the steps that take us from a decision to drill a well or wells, to delivered oil and gas? How do we decide what we need and where to get it? How are the cost trade-offs defined and constraints worked around? How is the system optimized across multiple projects and customers?

Integration matters, too. Choose and customize a system that will learn new steps. Also, make sure the various computer programs can talk to each other. The next phase of execution is then testing.

Phased approaches and pilot projects can be helpful in managing execution risks, as well as in getting employee buy-in. It is important to be thoughtful in figuring out what to do first. Algorithms are relatively easy to implement for commodity industries or businesses, such as online retailers. Not so much in businesses, where there is a large volume of very similar, but not uniformly standard, products and services, or manufacturing businesses where customization is the norm.

There are also risks to staying in the shallow end too long. Comprehensive business transformation will be required, to survive in the future oil and gas industry. Too much time spent making small changes could result in organizations finding themselves left behind. To avoid this, small steps should be part of a larger strategy that is marching forward on the path to digital transformation.

Accept what the data tells you. You must be willing to act on the insight provided by data analytics. By definition, any value-added big data approach leads you to a different place from instincts. Occasionally, deep data dive results can be a little counterintuitive. This is particularly true when a process is subject to multiple risks that can increase cost or reduce speed.

Delivery logistics are a perfect example. On journeys with multiple legs and hand-offs, there’s a lot that can speed you up or slow you down or stop you. Quantifying the impact of those risks, and making the right decision, is a tough job. A person working alone might oversimplify and make the wrong decision. Much like flying an airplane by the instruments is safer than flying visually, running a business by the numbers will be much more profitable than running it on the basis of what you can see on the surface.

THE FIRST STEP

Where does this all go? Will robots ever control every industrial process from end to end? Not any time soon. What will happen is likely to be more of an evolution than a revolution. The most ubiquitous and human of activities—such as driving—are being automated. It’s just a matter of time before other things that could once only be done by humans will be done by machines, directed by computers. That includes the drilling of oil wells.

From the dawn of the industrial age, many workers have instinctively recoiled when machines have been introduced to the workforce. Science fiction writers have spun many a story about dystopian nightmares around machines and technology. Despite initial fears or reservations, the digital evolution is about producing more oil and gas, and saving customers a little money.

Views reflected in this article are those of the author and are not necessarily held by the global EY organization, or its member firms. For more information, visit ey.com/digitaloil. ![]()

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)