New resin-coated 100 mesh sand reduces proppant flowback, enhances safety

Over the last several years, E&P companies throughout North America have sought innovative ways to optimize well performance and lower their cost per boe. They also strive to meet government regulations and company guidelines to protect worker health and safety. Operators have adjusted many completion designs by shifting to slickwater fluid systems and increasing proppant intensity per lateral foot. Large volumes of small-grained, uncoated frac sand (such as 100 mesh) are used in slickwater systems, to stimulate reservoir microfractures and extend propped fracture length. Due to the small particle size of 100 mesh sand, there may be a significant amount of dust produced when the uncoated proppant is transferred on location and pumped downhole.

Revised government restrictions affecting hydraulic fracturing will severely impact the completion designs of companies using 100 mesh and other mesh sizes of uncoated sand. Not only can uncoated sand increase the amount of respirable silica dust on a wellsite, it also can increase the risks of proppant flowback and fines generation that negatively impact the well’s production.

RESPIRABLE SILICA DUST REGULATIONS

The U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA) published its final rule for occupational exposure to crystalline silica. This rule improves previous exposure limits and establishes a new permissible exposure limit (PEL), calculated as an 8-hr, time-weighted average of 50 micrograms of respirable crystalline silica per cubic meter of air (50 µg/m3). OSHA also requires other provisions for employee protection, such as preferred methods for controlling exposure, respiratory protection, medical surveillance, hazard communication and recordkeeping.1

OSHA requires that companies follow the hierarchy of controls (relying primarily on engineering controls and work practices) to meet the established ruling. The agency believes that primary reliance on respirators to protect workers is generally inadequate when feasible engineering and work practice controls are available. These new regulations are in alignment with existing North American exposure limits. The Canadian government agencies in the provinces of British Columbia, Alberta, Manitoba, Newfoundland/Labrador, Nova Scotia and Prince Edward Island have an existing PEL of 25 µg/m3, which is half of the newly updated OSHA PEL. The Canadian provinces of Ontario, Quebec and New Brunswick have an existing PEL of 100 µg/m3. The Canadian province of Saskatchewan has an existing PEL of 50 µg/m3.2

SOLUTION

One of the engineering controls presented is dust suppression. As a means of controlling respirable crystalline silica dust using stabilization, dust suppression holds down dust particles by physical or chemical means. Resin-coated proppants (RCP) fall into this category of engineering controls to reduce respirable crystalline silica dust.

All of Hexion’s resin-coated proppants show improved dust control compared to uncoated frac sand, but a new solution is needed for 100 mesh frac sand, which can represent the worst-case dust scenario among sand sizes used in hydraulic fracturing. Hexion’s kRT 100 proppant (Fig. 1) is a curable, resin-coated, 100 mesh sand (RCS 100) that is proven to reduce the amount of proppant flowback and respirable silica to levels below the new OSHA and existing Canadian PELs.

FIELD DATA

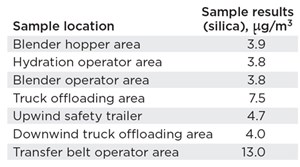

In October 2015, Hexion partnered with a major operator to reduce dust exposure to employees on location. The well in La Salle County, Texas, was a horizontal well that used 9.7 million lb of proppant, 100% of which was RCS 100. To measure respirable silica dust, a third-party industrial hygiene company placed dust measurement devices in various locations—blender operator area, blender hopper area, transfer belt operator area, truck offloading area, hydration operator area—downwind of the truck offloading area, and upwind of the safety trailer area. The measurements were taken during the first two stages of the job. The study showed that there were no instances of the silica dust exceeding the new OSHA or existing Canadian requirements, Table 1. In addition to reducing the exposure to respirable silica dust below the limits set by OSHA for wellsites, an E&P company stated that the curable, resin-coated 100 mesh sand successfully reduced proppant flowback.

LABORATORY DATA

The innovative resin system used in RCS 100 was developed by combining resin chemistry expertise, manufacturing capabilities, and more than 30 years of experience in designing resin-coated proppant. As demonstrated by the field testing, this product reduces dust to below the OSHA and Canadian dust limits, while simultaneously delivering the added performance benefits of proppant consolidation and proppant

flowback reduction.

To prevent pump cavitation, RCS 100 was designed to exhibit excellent wettability. The lack of air entrapment and wettability can be seen in Fig. 2. The ultra-fine respirable dust present in uncoated 100 mesh sand also can be seen. In this simple test, uncoated 100 mesh sand and RCS 100 were loaded at 2 lb/gal in fresh water and agitated for the same amount of time. The two containers were allowed to settle for 2 hr and 50 min., with photos taken at 30 sec, 1 min., 20 min., 1 hr, and 2 hr and 50 min. After 30 sec, the lack of dust in RCS 100 was readily apparent. By comparison, after 2 hr and 50 min., the uncoated 100 mesh sand was still cloudy with suspended ultra-fine respirable dust.

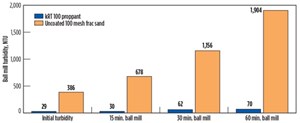

Additional dust can be generated when proppant is transported to its final destination, due to mechanical abrasion. Ball mill tests were conducted to simulate the effects of mechanical abrasion associated with product transfer, such as trucking, rail, belt travel and pneumatic transfer. Proppant in the ball mill was subjected to a force of 30-40 lb/grain of sand over a prescribed period of time. A turbidity test was then conducted to measure the dust generation caused by ball milling. After 60 min. of ball milling, RCS 100 remained well below the American Petroleum Institute (API) turbidity requirement of 250 NTU, Fig. 3. Prior to ball mill testing, the initial turbidity of uncoated 100 mesh sand exceeded the API turbidity requirement of 250 NTU. During the ball mill testing, the turbidity of the uncoated 100 mesh sand nearly tripled after 30 min. After 60 min. of ball milling, the turbidity of the uncoated 100 mesh sand was nearly five times the initial turbidity.

While dust control is one benefit of the new resin-coated 100 mesh proppant, the primary benefit of using curable, resin-coated proppants is to enhance the performance of the consolidated proppant pack in the formation. Curable, resin-coated proppants significantly reduce proppant flowback, compared to uncoated sand and ceramics. The coating’s ability to form grain-to-grain bonds helps distribute stress throughout the proppant pack, and reduces the effects of point loading on each individual grain of substrate. The resin coating encapsulates fines that can be generated due to closure stress.

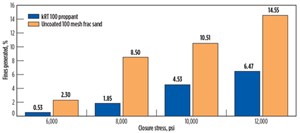

Proppant fines generated downhole can lead to reduced fracture flow capacity and decreased production.3 Wet, hot crush testing was conducted to simulate downhole conditions and measure the fines generated. In this test, proppant was loaded into a crush cell at 2 lb/ft2 with 2% KCl water. The cell was then placed under 1,000-psi closure pressure at 200°F for 24 hr. After 24 hr, standard crush tests were performed, following API procedures at various closure stresses, Fig. 4. At 12,000 psi, uncoated 100 mesh sand created 125% more fines than RCS 100.

Unconfined compressive strength (UCS) testing is a method to determine the ability of a proppant to form a consolidated proppant pack. A proppant that can form a consolidated proppant pack through grain-to-grain bonding will reduce proppant flowback and minimize embedment. RCS 100 consolidated into a solid proppant core, unlike uncoated 100 mesh sand, which does not consolidate, Fig. 5.

SUMMARY

RCS 100 allows operators to continue stimulating microfractures while remaining compliant with new OSHA dust regulations. In addition to reducing dust generation for a safer work environment, RCS 100 users can expect to see improved production, compared to uncoated 100 mesh sand, since proppant failure (crushing) and proppant flowback can be reduced. RCS 100 provides all of the benefits of traditional, curable, resin-coated sand, such as proppant flowback control, reduced proppant fines and decreased embedment, compared to uncoated 100 mesh sand. By providing these benefits, kRT 100 resin-coated proppant helps operators maximize well production. ![]()

REFERENCES

- “OSHA’s final rule to protect workers from exposure to respirable crystalline silica,” https://www.osha.gov/silica/, March 2016.

- “Mitigating crystalline silica exposure in the work place,” The Petroleum Services Association of Canada, https://www.psac.ca/leadership/health-safety/mitigating-crystalline-silica-exposure-in-hydraulic-fracturing/, 2016.

- Coulter, G. R. and R. D. Wells, “The advantages of high proppant concentration in fracture stimulation,” SPE paper 10.2118/3298-PA, June 1972.