Gas detection on the Terra Nova FPSO

Terra Nova oil field is on the Grand Banks, 217 mi east-southeast of the city of St. John’s in the Canadian province of Newfoundland and Labrador, and is the second-largest producing oil field in eastern Canada. The total recoverable oil reserves in the field are estimated by the Canada-Newfoundland and Labrador Offshore Petroleum Board (C-NLOPB) to be 419 MMbbl. The owners of Terra Nova field are: Suncor Energy, operator (37.675%); Exxon Mobil (19%); Statoil (15%); Husky Energy (13%); Murphy Oil (10.475%); Mosbacher Operating Ltd. (3.85%); and Chevron Canada (1%).

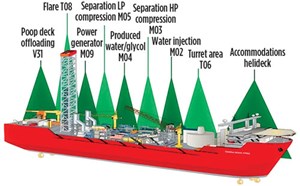

Production from the field began in early 2002, through the use of an FPSO vessel. This was the first development in North America to use FPSO technology. One of the largest FPSO vessels ever built, the Terra Nova is 958 ft long and 149 ft wide, holds 960,000 bbl of oil, and accommodates up to 120 personnel while producing.

GAS DETECTION HISTORY

The original Terra Nova gas detection system was designed to utilize a combination of point detectors and line-of-sight (LOS) detectors, based on infrared (IR) technology, with the bulk of coverage being provided by the LOS type. Since the facility first started production in 2002, there have been ongoing issues with the reliability of the LOS detectors. The most significant issue has been performance during adverse weather conditions. During periods of fog or snow, many detectors would report a blocked beam fault condition and, depending on the situation, some would falsely detect gas.

As a result, Suncor would frequently be forced to assign technicians to clean the lenses and return the units to service. Simultaneously, operational staff would also place inhibitors on many detectors to prevent inadvertent plant trips. In any zone, once a threshold of 50% of detectors requiring inhibitors had been crossed, temporary portable detectors were deployed, and the number of personnel would increase in the affected areas to monitor for gas releases.

By 2010, parts of Terra Nova field were beginning to produce hydrogen sulfide (H2S) in the well fluids. As toxic gases were not expected in the original design, the fixed gas detection system did not incorporate dedicated H2S detection, and a multi-disciplinary team was assembled to assess, and upgrade, the overall gas detection system. The team involved personnel from safety, risk analysis, operations, instrumentation and controls engineering. Based on the need to upgrade the gas detection system to detect H2S and the LOS detector performance issues, several projects were initiated.

The first initiative was to build a gas dispersion model for the Terra Nova FPSO and use this analysis to complete a comprehensive gas detection evaluation and optimization study. In parallel, Suncor began to investigate and trial various gas detection technologies that could address the problems with the existing system, and detect both flammable and toxic gas releases.

EVALUATION OF GAS DETECTION SYSTEM

Detailed analysis, based on computational fluid dynamics (CFD) modeling, was performed for the Terra Nova FPSO by GexCon. The overall objective of the analysis was to test and optimize system performance, and suggest improvements for the existing system and detector layout. The process included:

- Accurately representing ventilation conditions across all process modules

- Simulating a range of realistic gas leak cases and explosions to establish dangerous cloud sizes for each module

- Suggesting, and benchmarking, a range of detector designs and layouts for each module

- Arriving at a recommended optimum system for each module, accounting for limitations on number and type of detectors, input/output limitations, and voting schemes

- Ensuring sufficient performance for both toxic and hydrocarbon gas detection.

In aggregate, more than 1,400 gas leak scenarios were simulated and used in the evaluation, optimization, detector selection and overall design of the upgrade to the gas detection system.

The CFD model FLACS was chosen in the present study, because it allows:

- Simulation of the relevant toxic and flammable gaseous releases

- Modeling of the detailed geometry within the facility

- Simulation of both natural and forced ventilation within the facility

- Evaluation of gas concentration measured by line and point detectors

- Evaluation of danger potential for the dispersion cloud

- Ability to perform parametric sensitivity and optimization studies.

The geometry of the Terra Nova FPSO was based on a computer-aided design (CAD) model, as shown in Fig. 1. The quantitative evaluation of the GDS in the process modules was based on testing the performance for a large set of realistic gas leak scenarios. This means that ventilation conditions and gas leak properties had to be modeled as accurately as possible. The local ventilation conditions were critical in understanding the formation and migration of flammable or toxic gas clouds. The ventilation conditions were determined by the wind speed and direction; the heading of the FPSO; large-scale effects from modules and buildings, upwind and downwind of the area of interest; as well as smaller-scale effects from buildings, walls, equipment and piping inside the area of

interest itself.

SELECTING THE RIGHT TECHNOLOGY

Since it commenced operation in 2002, the Terra Nova FPSO has relied primarily on LOS detection. Therefore, Suncor’s preferred option was to determine if LOS technology existed that could replace its existing detectors and provide coverage for both flammable and toxic gas leaks. This would minimize structural modifications required to mount new units, avoid having to run new cables and trays, thereby minimizing construction time and cost. An extensive search eventually led the Suncor team to lab test, field trial and ultimately select the Enhanced Laser Diode Spectroscopy (ELDS) technology. This technology, developed by Senscient, had the capability of combining toxic and flammable gas detection in a single LOS detector while significantly improving the performance and reliability of the FPSO’s overall gas detection system.

In February 2011, a trial ELDS unit was acquired and subjected to qualification testing at the Terra Nova onshore distributed control system (DCS) simulator. Over a period of two weeks, stringent performance tests were conducted on the device, under four conditions that were known to generate problems for the existing IR detectors:

- Simulated fog, using water mist

- Direct water spray on the device lenses

- Plastic of various types placed in the beam path

- Snow placed over the lens (approximately 1 in. thick).

The test results showed no issue with performance for all four conditions.

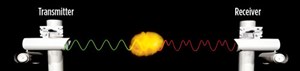

Using a transmitter-receiver configuration, ELDS systems detect and measure gas concentrations at specific target gas absorption wavelengths over distances of up to 655 ft, Figs. 2 and 3. The transmitter uses highly reliable, solid-state, laser diode sources, similar to those used in telecommunications applications to generate a laser beam. The receiver measures absorbance changes when a combustible or toxic gas passes through the laser beam. One of the key techniques that enables ELDS to detect a small fractional absorbance, and eliminate a false alarm, is harmonic fingerprinting. A harmonic fingerprint is a specific set of harmonic components introduced by target gas absorption, where the relative amplitudes and phases of the components are known and specific to the target gas absorption line that is being scanned.

Using a small, retained sample of target gas inside the transmitter, the temperature and wavelength modulation currents applied to the transmitter’s laser diodes are actively controlled to lock the lasers, such that absorption by target gas produces specific harmonic fingerprints. The relative amplitudes and phases are so unique that only absorption by the specified target gas produces a signal with the desired harmonic fingerprint. Noise absorption by atmospheric gases, and coherent interference effects, never produce signals with the harmonic fingerprint, enabling an ELDS-based gas detector to eliminate false alarms. In addition to maintaining a harmonic fingerprint lock, the gas reference cell enables remote, on-command, electronic functional testing of the gas detector, either locally or from the control room under any condition.

In the test, the transmitter simulated a predefined quantity of target gas by directing the laser beam through the reference cell. ELDS units are programmed to conduct a validity test every 24 hr. The results of detector functionality testing are gathered and logged automatically. The presence of a gas reference cell is an innovation that improves reliability and reduces maintenance, which eliminates the need for technicians to carry cylinders of hazardous gases through the FPSO to test gas detectors.

IMPLEMENTATION OF THE RETROFIT AND UPGRADE

Once onshore testing was done, a dual, methane-H2S ELDS detector was installed in May 2011, replacing an issue-prone IR LOS device. The distance between the transmitter (Tx) and receiver (Rx) for this installation was approximately 112 ft. During a trial period that lasted approximately 24 months, the ELDS detector performed very well, with zero spurious trips. The only issue identified was a loose mounting bracket that resulted in misalignment. Following the successful offshore trial, a decision was made by Suncor to replace all existing IR LOS gas detectors on the Terra Nova FPSO with the ELDS technology. In aggregate, 141 IR LOS detectors were slated for replacement. A recommendation from the study by GexCon added another 17 ELDS detectors to provide for additional coverage. Therefore, the overall retrofit and upgrade plan called for the decommissioning of 141 IR LOS detectors and the installation of 158 ELDS detectors.

Retrofitting the FPSO, while it was on location, in full operation, required significant planning. A thorough work package was developed which provided a plan for the decommissioning of the existing IR detectors, installation of the new ELDS detectors, and training of personnel. Change out of the LOS detectors commenced in 2013. As of July 2014, 78 of 158 ELDS detectors were installed, with the remaining devices scheduled to be changed through the remainder of 2014 and into 2015.

RESULTS AND DISCUSSION

The performance of the upgraded system has been exceptional. Prior to the upgrade, the FPSO experienced three to five plant trips, more than 100,000 fault indications, and 20 to 25 unrevealed failures per year. Statistics from the FPSO data historian, maintenance management system, and lost production tracking register were analyzed to quantify this performance.

IMPACT ON SAFETY PERFORMANCE

A review of the maintenance management system showed that there was an average 21 unrevealed gas detector failures per year from 2009 to 2013. The signal that these IR devices were sending to the control system indicated full health. However, they failed to respond to a function check. The ELDS detectors address this problem by completing a daily diagnostic check and signaling a fault, if there is an issue. As of Dec. 31, 2014, the FPSO had not recorded a single unrevealed failure with the laser-based gas detectors. Start-up and shutdown of a facility introduce risks that are not present when a plant is in steady-state operations. By reducing the number of spurious trips, the time spent in start-up or shutdown modes is reduced, thereby decreasing the risk to

the facility.

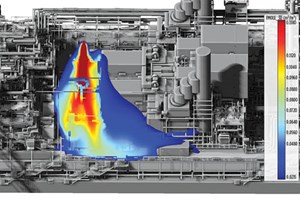

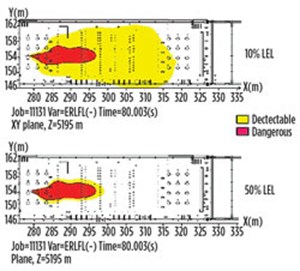

The laser-based sensors installed on the FPSO have a minimum detection threshold that is much lower than the older IR-based detectors. Instead of a hydrocarbon detection threshold of 1 LELm/2.5 LELm (low/high alarm), the laser-based detectors can be set to a threshold of 0.2 LELm/1 LELm (low/high alarm), without experiencing any drifting and related spurious alarms. The effect of this five-fold increase in sensitivity is that the detectable volume of any gas cloud is larger. Figure 5 shows two plots of the same simulated gas leak. The red zone is flammable gas, whereas the yellow zone represents detectable volume with a sensitivity of 10% LEL and 50% LEL, respectively for the top and bottom plots. Increasing the sensitivity of detectors increases the detectable volume and makes it more likely that any given detector will be exposed to detectable gas before the flammable volume reaches a dangerous size, Fig. 4. Furthermore, the H2S content on the FPSO means even small leaks can be hazardous, thus, increased sensitivity is an important tool to ensure

worker safety.

A comprehensive dispersion analysis based on worst-case H2S concentrations in the production stream was performed for the entire FPSO. This study revealed that hazardous levels of H2S could occur in the port half of module M04, the area of the process facility where regeneration of glycol and treatment of gas and produced water takes place. For other areas of the FPSO, results obtained from the gas dispersion modeling demonstrated that the H2S concentrations were low, and, thus, detection was adequately ensured via the optimized hydrocarbon GDS. Consequently, a dedicated H2S detection system was developed and installed in the M04 module with laser-based LOS devices. The installed system satisfied the performance criteria for H2S detection.

IMPACT ON MAINTENANCE AND OPERATIONS

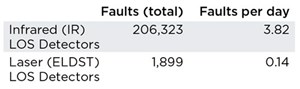

A review of performance data from the FPSO data historian shows dramatic improvement over the IR devices in spurious trip avoidance. The key metric reviewed was the number of faults / blocked beam indications. Performance data were reviewed from January to December 2011 for the IR-based detectors, as the FPSO was off-station, for maintenance, for portions of 2012 and 2013. Data from June 2013 to June 2014 were used to capture the performance of detectors that had been changed to laser-based systems. As the number of devices and time in service for the two groups is not equal, a metric of fault rates per detector day is used for comparison purposes (total faults/sum of days in service). A summary of the data is provided in Table 1.

It should be noted that in both cases, there were a large number of faults attributed to detectors chattering in and out of a fault condition. The table above includes all faults, regardless of the cause. In the case of the laser-based detectors, 1,561 of the 1,899 faults were attributed to two detectors that had alignment issues over several days before being corrected. Outside of these two detectors, the fault rate per detector was approximately 0.025 faults per detector, per day, and the vast majority were due to alignment issues. For the IR detectors, one device accounted for nearly half of the faults. This IR device had a failed source that resulted in a chattering fault for a six-month period while waiting on parts for replacement. Overall, the fault rate, not counting the problem detector, was significantly higher for IR than for ELDS, with 1.1 faults per detector day, with the majority due to weather, dirty optics and alignment.

With such a significant decrease in the number of faults, the requirement for technician response and troubleshooting has been reduced drastically. From 2009 to 2013, an average 234 maintenance work orders per year was generated, relating to IR LOS detectors being in fault. Note that this number does not include the significant number of maintenance call-outs during conditions of limited visibility (rain, fog, mist and snow) to clean detectors, as these calls are not tracked. From June 2013 to July 2014, there were only 13 maintenance work orders created, relating to issues with laser-based devices.

IMPACT ON PRODUCTION

Historically, the FPSO has experienced three to four production trips per year, due to false gas detection. These trips have resulted in production deferments of approximately 50,000–100,000 bbl/yr. During a trip initiated by gas detection, emergency shutdown valves are closed quickly, equipment is tripped, and gas inventory is sent to the flare system. Shutting down the plant in this manner has potentially damaging effects on plant equipment, such as generators and gas compressors. The FPSO experienced damage to process equipment during emergency shutdowns several times prior to the installation of the laser-based gas detectors, resulting in prolonged outages and significant repair costs. Conversely, there has not been a single instance of false gas detection with the laser-based technology.

CONCLUSION

The advent of sour gas in the production fluid stream, and detector failures, were the catalysts for an extensive overhaul and upgrade of the gas detection system on the Terra Nova FPSO. This vessel is a remote facility with limited egress. Therefore, any hazardous gas release in the facility requires complete production shutdown, blow-down of available inventory and isolation of electrical equipment that is not Zone 1-rated. In particular, false alarms from gas detectors were resulting in prolonged outages, damage to process equipment, and production deferments of approximately 50,000–100,000 bbl/yr.

In 2010, a multi-disciplinary team was assembled to assess and upgrade the FPSO’s overall gas detection system. The team involved personnel from safety, risk analysis, operations, instrumentation and controls engineering. A detailed facility analysis, based on computational fluid dynamics modeling, was performed. In aggregate, more than 1,400 gas leak scenarios were simulated and used in the evaluation, detector selection process, optimization and overall design of the upgrade to the gas detection system. Laser-based technology was selected to replace infrared gas detection technology after extensive testing in both onshore and offshore environments.

Analysis of data from the Terra Nova data historian, maintenance management system and lost production tracking register demonstrate that Terra Nova was able to:

- Eliminate false alarms

- Increase gas leak detection coverage

- Receive earlier warning for preventative and remedial action

- Reduce maintenance requirements and exposure of operations personnel to hazardous locations and gases

- Improve the reliability of the FPSO’s overall gas detection system.

Implementation of advanced, laser-based, gas detection technology can result in a significant improvement in safety, reliability and process uptime in industrial facilities where the threat of a toxic or flammable gas leak exists. ![]()

REFERENCES

- Barua, R., A. Brattateig, Z. Bath and E. Sharpe. “Case Study: Laser-based gas detection technology and dispersion modeling used to eliminate false alarms and improve safety performance on Terra Nova FPSO”, 17th Annual Symposium, Mary Kay O’Connor Process Safety Center, Hilton Conference Center, College Station, Texas.

- What's new in production (February 2024)

- Prices and governmental policies combine to stymie Canadian upstream growth (February 2024)

- U.S. operators reduce activity as crude prices plunge (February 2024)

- U.S. producing gas wells increase despite low prices (February 2024)

- U.S. drilling: More of the same expected (February 2024)

- U.S. oil and natural gas production hits record highs (February 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)