|

| All three lower-completion intervals in the well were stimulated successfully with the MST system, one of the deepest, multi-zone sand-control completions in the industry. |

|

The Lower Tertiary play in the Gulf of Mexico (GOM) is a proving ground for E&P technologies capable of withstanding harsh HPHT conditions. The vast ultra-deepwater play is an oil-bearing reservoir with 1,200-ft gross sand thickness. At water depths ranging from 8,200 ft to 8,900 ft, the reservoir depths are greater than 26,000 ft TVD, with reservoir temperatures greater than 250°F and pressures exceeding 19,000 psi. The formation is composed of stacked thin beds of sand and fine-grained siltstone intervals that have, effectively, no vertical permeability and an occasional cap of thick salt/sediment layers. The region also provides an opportunity to achieve industry firsts by applying advanced technologies at record depths.

Since the start of production from its Lower-Tertiary Cascade and Chinook (C&C) fields in 2012, Petrobras has relied consistently on advanced technology applications. Located in the Walker Ridge area, 180 mi off the Louisiana coast, the fields are tied to the GOM’s first floating production, storage and offloading (FPSO) vessel. These fields represent the outer limits of ultra-deepwater development, Fig. 1.

|

| Fig. 1. Petrobras’ Cascade and Chinook fields are at the outer limits of the current developments in the deepwater Lower Tertiary trend. |

|

By the end of 2013, Petrobras completed five wells (three wells in Cascade and two in Chinook), each of them producing from two separate pay intervals—an upper interval known as Wilcox 1 and a lower interval called Wilcox 2. While these wells have been producing as expected, their completion designs have not afforded Petrobras the opportunity to accurately measure the production contribution from each individual interval. The operator has relied on the use of tracers to qualitatively measure production from all of the zones, and on multiphase flowmeters at the wellhead to monitor the total, commingled production from each well.

This limitation, and the need for more quantitative measurements of each interval’s flow characteristics, prompted Petrobras’ reservoir group to call for the development of an intelligent well completion. Such a system, the first of its kind in the Lower Tertiary, would allow for a more quantitative understanding of each pay interval’s contribution to the overall production, while providing greater zonal control.

COMPREHENSIVE COLLABORATION

Petrobras selected the new Cascade 6 well as its candidate for the first intelligent well system (IWS), and tapped Baker Hughes to develop the necessary completion technologies. The well, a subsea completion with an 8,211-ft water depth and total well depth of approximately 27,000 ft, required a comprehensive completion package specifically tailored to the challenges encountered in producing from the two zones. Both companies had collaborated successfully on the previous completions in the C&C project, and built on that collaboration to develop the IWS for Cascade 6.

The collaboration began with upfront planning meetings, in which representatives from each company discussed the production and operational goals for the well. This team then jointly developed the final completion design that would meet Petrobras’ goals and minimize the need for complex, costly and invasive interventions. Petrobras carried this collaborative team philosophy throughout the project. Rather than make decisions behind closed doors and then give Baker Hughes direction, both companies discussed each phase of the well completion development and design. Similarly, the completion equipment design, manufacturing and quality processes were a collaborative effort. This open process of information sharing and decision-making helped streamline development and planning, and minimized the risk of any unforeseen surprises that might delay the project.

FINAL DESIGN WITH MANY FIRSTS

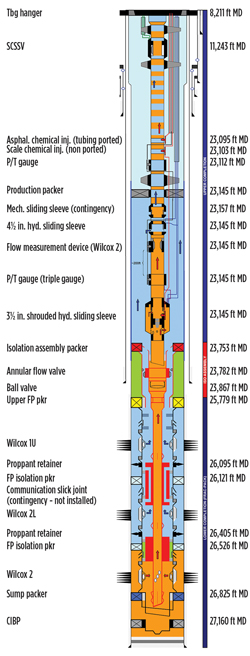

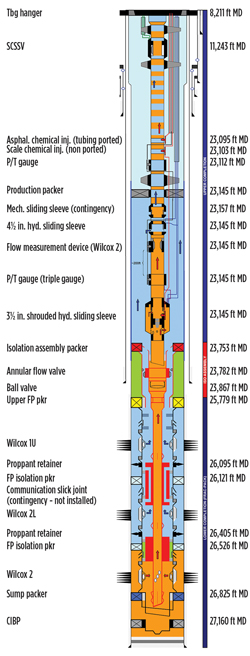

The final design for the Cascade 6 well consisted of an upper and lower completion, which would isolate the upper pay zones (two hydraulically fractured intervals from the Wilcox 1 interval) from the lower zone (one hydraulically fractured interval from the Wilcox 2) and allow for selective production from each zone, if required, Fig. 2.

|

| Fig. 2. Completion schematic showing the upper and lower portions. |

|

The major components in the upper completion include:

- Seven downhole pressure/temperature gauges, which besides monitoring the downhole temperature and the pressure of the production intervals, are used to infer the water cut (fluid density) and the flowrate from Wilcox 2 with a Venturi flowmeter. The gauges also provide information to assist casing pressure (Annulus A) verification throughout the production life of the well.

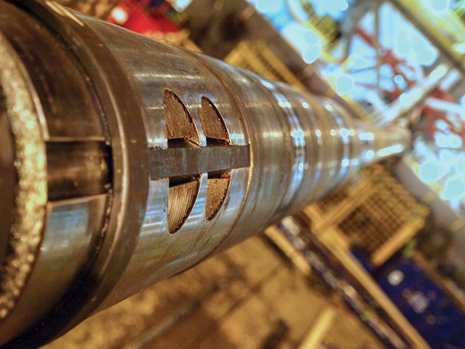

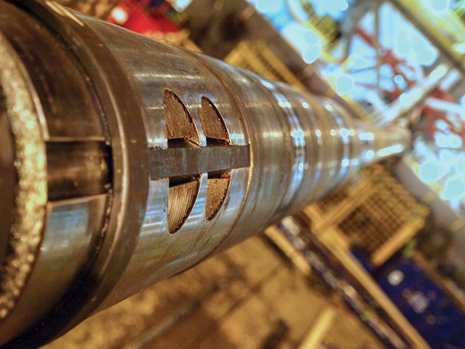

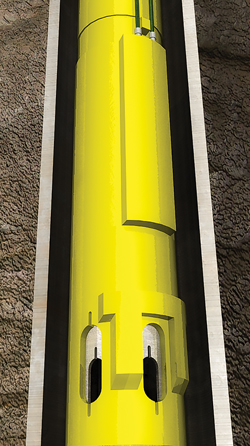

- A 4½-in. hydraulic sliding sleeve (DHFC downhole flow control valve), rated to 12,000 psi differential pressure and used to control production from Wilcox 1, Fig. 3. This is the highest pressure-rated system of its kind designed and installed, to date, by Baker Hughes.

|

| Fig. 3. The system’s hydraulic sliding sleeve valves are rated to 12,000 psi. |

|

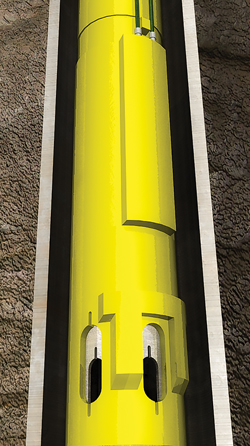

- A 3½-in. shrouded hydraulic sliding sleeve (DHFC valve), also rated to 12,000 psi differential pressure and used to control production from Wilcox 2.

- Two separate chemical injection systems, one for paraffin inhibitor and one for scale inhibitor. The paraffin injection system injects treatment chemicals above the retrievable production packer, while the scale inhibitor injection system includes a line that carries scale inhibitor into the shroud of the 3½-in. DHFC valve. This unique design allows scale inhibitor treatment into the tubing for both zones through only one chemical injection valve, regardless of the position of the hydraulic sliding sleeves.

- A feed-through packer with six ¼-in. control line feed-through ports.

- Three flat packs that contain three ¼-in. hydraulic control lines for the DHFCs, two ¼-in. hydraulic control lines for the safety valve, two ⅜-in. lines for chemical injection and one ¼-in. TEC line for the gauges.

- A Venturi flowmeter to measure production from the Wilcox 2 zone. While Venturi meters have been deployed in other subsea assemblies, this marked the deepest installation to date. The use of this flowmeter answered the operator’s need to more accurately estimate the production contribution from each zone. With the Wilcox 2 production measured with the Venturi device and the total commingled output available from the multiphase flowmeter at the wellhead, the production from Wilcox 1 can be calculated with ease.

- A next-generation Neptune EP safety valve, which includes design upgrades for improved operational efficiency and reliability. This marked the first Baker Hughes installation of this upgraded Neptune valve design.

- The TORRENT multi-zone, single-trip (MST) system to stimulate the three zones (two in Wilcox 1, one in Wilcox 2) as an alternative to a conventional stack frac-pack operation. Petrobras had experience using the MST on previous C&C wells, but this well represented the first deployment of the MST system with an intelligent well system (IWS) completion and also the first time that the same service tools were used throughout the hydraulic fracturing operations.

Baker Hughes also provided a re-closeable annular flow valve with a 50-ft tieback receptacle, which is part of the isolation assembly and was used as a mechanical barrier throughout the upper completion deployment and commissioning operations.

PUTTING CONTINGENCIES IN PLACE

Given the well’s depth and high upfront capital expense, coupled with the objective to design and construct a completion to withstand production for 20 years or longer, Petrobras developed an enhanced well design to minimize the risk of equipment failure and interventions. To that end, both companies worked together to include multiple contingencies into the design, that would keep production flowing from each zone, if the primary equipment would fail.

Such contingencies include the capability to install one single-scale inhibitor injection point, to be able to treat the entire production string down to the lowest hydraulic sliding sleeve, even in the event that the valve is shifted closed. Among other flow assurance concerns, the scale inhibitor is designed to avoid buildup along the moving parts of the hydraulic sliding sleeves that might prevent their normal operation. This was considered a much more cost-effective measure, compared to installing a second scale inhibitor injection point (one below each valve), with implications not only to the well design (additional ⅜-in. control line), but also to the subsea tree system.

A 4½-in. mechanical sliding sleeve was installed above the 4½-in. DHFC valve (upper) as another contingency. The sliding sleeve is kept in the closed position during normal well operations. If the upper DHFC valve should fail (e.g., in case a plug in the control line prevents its normal hydraulic operation or any attempt to mechanically override it), then the mechanical sliding sleeve can be opened to allow production from Wilcox 1 to reach the surface. Conversely, if the 4½-in. DHFC valve is stuck open and production from Wilcox 1 needs to be shut off, a fit-for-purpose separation sleeve could be installed to straddle the DHFC ports, effectively shutting off production from Wilcox 1, while allowing continued production from Wilcox 2.

Contingencies also exist, in the event that production from Wilcox 2 needs to be shut off. If the 3½-in. shrouded DHFC valve (which controls Wilcox 2 flow) cannot be closed hydraulically or mechanically, the valve includes a sealbore nipple profile above its ports. A plug can be installed in this nipple profile to shut off production from Wilcox 2. In the event that the shrouded valve is stuck in the closed position, production from Wilcox 2 can be restored by pulling the plug used to divert the flow into the shroud housing. With the plug removed, Wilcox 2 production flows straight up the tubing, rather than perforating the sliding sleeve.

PRE-PLANNING PAYS OFF

One of the keys to success on both the upper and lower completions, and ultimately, the entire installation, was the significant amount of planning, collaboration and preparation that took place from the completion design conceptual phase, through the procedure elaboration and peer review meetings. This involved not only Petrobras and Baker Hughes, but all the main contractors, to plan the equipment make-ups prior to going offshore and final deployment. To minimize rig time, subassemblies were built on land, function-tested and then shipped offshore.

For example, the MST subassemblies were made up and spaced out to match the perforation intervals provided by Petrobras. Once the perforations were finalized, they were laid out with the MST system to ensure a proper space-out, using Baker Hughes’ real-time tool position, visualization and design software. Because the MST system uses multiple shifters, it was also verified in the design software that shifting one sleeve did not inadvertently shift another sleeve. Once the space-out was set, Baker Hughes technicians built the equipment, and loaded it to go offshore.

The upper completion was planned, and the equipment was built to minimize rig time. This was accomplished by building up subassemblies and pre-installing the majority of the hydraulic lines prior to going offshore. The lines were passed through the feed-through packer, routed and terminated throughout the subassembly. These were tested onshore and shipped ready to run downhole.

The onshore testing protocol included numerous pressure and communication tests on each sub-assembly to ensure reliable operation prior to moving offshore. Twenty full hydro-tests were performed on the individual sub-assemblies, and 46 strip chart tests were conducted on the fittings for the control lines routed through the sub-assemblies, Fig. 4. Petrobras representatives were present for all tests, and witnessed, first-hand, the operation and testing protocol.

|

| Fig. 4. Make-up of the intelligent well system assembly in preparation for hydro testing. |

|

The preplanning process onshore provided a valuable lesson in the importance of making up and testing the sub-assemblies as early as possible. The completion team uncovered some configuration issues during make-up that required minor modifications to the equipment. Because these issues were identified well before the IWS was shipped to the rig, the changes were conducted in a methodical manner, without impacting the operation schedule.

Once the sub-assemblies arrived offshore, a joint Baker Hughes-Petrobras team, along with other key contractors, worked together to prepare the sub-assemblies and deploy them downhole. This deployment was highly efficient and safe, thanks largely to the fact that the same joint team had worked together on previous completions. The familiarity of the deployment crew benefitted all of the rig operations, from picking up tools to testing and deployment.

Due to the importance of this IWS completion, and the fact that it had never been installed at these depths and pressures, the operator allowed for as much time as required to test the sliding sleeves. The information from these tests will be used in the future as a baseline to evaluate the shifting of the sleeves.

SUCCESSFUL RESULTS

|

| Fig. 5. The TORRENT multi-zone single-trip (MST) system was used to stimulate the Wilcox 1 and Wilcox 2 formations. |

|

All three lower-completion intervals in the well were stimulated successfully with the MST system, one of the deepest, multi-zone sand-control completions in the industry, by pumping more than 1 million lb of proppant across all three zones in one trip, Fig. 5. The entire stimulation job was completed in nine days, a savings of 12 days of rig time. The IWS upper completion installation for Cascade 6 was run in 12 days, which is three to four days under what could be expected. The well has been on production since early-January 2014 without an incident. The IWS completion that was created and successfully installed for Petrobras can now be used as a base model for other IWS systems going forward. Petrobras is now planning to use this same IWS design for its next well, Chinook 6.

REFERENCES

- Haddad, Z., M. B. Smith and F. D. De Moraes, “Designing multistage frac packs in the Lower Tertiary formation—Cascade and Chinook project,” SPE Drilling & Completions, Vol. 27, No. 1, 2012, pp 50-64, based on SPE paper 140498.

- Haddad, Z., N. B. Smith, F. D. De Moraes and O. Moreira, “The design and execution of frac jobs in the ultra-deepwater Lower Tertiary Wilcox formation,” SPE paper 147237, presented at the SPE Annual Technical Conference and Exhibition, Denver, Colo., USA, Oct. 30–Nov. 2, 2011.

- Moraes, F.D., O. Moreira, S. Ogier, Z. Haddad and J. Shipley, “Well completion operations in Cascade and Chinook fields—ultra deepwater challenges in the Gulf of Mexico,” IBP paper 3310, presented at the Rio Oil & Gas Expo and Conference, Rio de Janeiro, Brazil, Sept. 13-16, 2010.

- Ogier, K.S., Z. Haddad, O. Moreira, F. D. De Moraes and J. Shipley, “The world’s deepest frac-pack completions using a single-trip multi-zone system: A Gulf of Mexico case study in the Lower Tertiary formation,” SPE paper 147313, presented at the SPE Annual Technical Conference and Exhibition, New Orleans, La., Oct. 30–Nov. 2, 2013.

|