GLENN ADCOCK, Sanchez Oil and Gas; and BEN WELLHOEFER, SAID DAHER and ERIC FRUGE, Halliburton

To economically develop unconventional resource plays, such as the Eagle Ford shale in South Texas, multiple, complex hydraulic fracturing stages must be executed in the horizontal section of the wellbore. Traditionally, a plug-and-perforate (P-n-P) process has been used. However, inherent difficulties in the process often limited completion cycle time and created barriers to economic delivery of the hydraulic fracturing treatment.

The Eagle Ford shale in Zavala County, Texas, is similar to many high-carbonate-content oil shale formations. As with other shale plays, the industry has preferred using cemented lateral sections as the primary means of fracture-stage isolation, coupled with the P-n-P horizontal completion technique. This article describes an alternate completion method—cemented multi-stage sleeves (CMSS), which recently improved efficiency and reduced completion cycle time. The process, procedures used and lessons learned from applying this technology are discussed.

EAGLE FORD SHALE

The industry has seen a surge in unconventional resource play discoveries, both in the U.S. and internationally. These reservoirs present significant opportunity for hydrocarbon production, but also include challenges to make production efforts economical. To be capable of economically producing unconventional reservoirs, wellbores are typically drilled horizontally through the target formation. Then, multiple hydraulic fractures must be created throughout the target zone to enable production. The ultimate goal is to maximize stimulated reservoir volume (SRV), thereby obtaining maximum production while minimizing the cost per barrel of oil equivalent (boe).

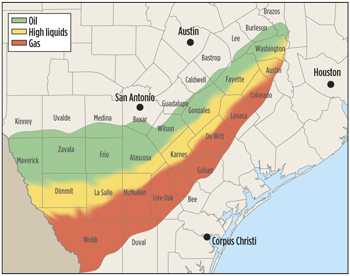

The Eagle Ford in Zavala County, Texas, is no different than the typical unconventional resource play and lies within the oil window of this shale play, which is similar to other oil-producing, high-limestone-content shale plays. This type of play necessitates placing proppant with adequate conductivity during the stimulation treatment to allow for oil production. The completion technique chosen must allow for placing larger-sized proppants to achieve the required conductivity.

Previously, the operator had developed wells in the oil window of the Eagle Ford shale in the same county. These wells were completed using the P-n-P technique; however, due to the nature of the P-n-P process, it presented barriers to efficiency. When the operator moved into a new field in the area, the decision was made to employ a new completion technique utilizing CMSS. This would allow for the evaluation of both techniques to determine if completion efficiencies could be gained while achieving the same completion goals.

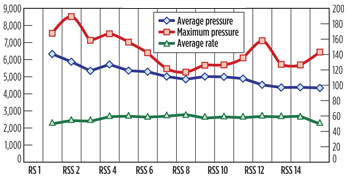

|

| Fig. 1. The Eagle Ford shale trend includes three windows—dry gas, high liquids and oil. |

|

|

| Fig. 2. The subject well in Zavala County, Texas, is in the Eagle Ford shale’s oil window. |

|

This article highlights the key well (location shown in Figs. 1 and 2) that successfully implemented the new completion, CMSS technique. The key well has been compared to averages from wells utilizing P-n-P to illustrate how the CMSS technique was able achieve the completion goals while drastically increasing completion efficiency.

THE CHALLENGE

A major challenge in unconventional reservoirs is developing more efficient integrated completion methods, to improve well economics and lower the cost per boe. This is particularly true when trying to balance well economics with production results (Ferguson, et al., 20121). This is due primarily to the current completion strategy, P-n-P, and the intervention that is necessary during the process to complete it during each fracture stage. While this process has improved over the last few decades with the advent of new technologies and processes, some downtime is always experienced. Additionally, oil shale reservoirs require enough formation to be stimulated to provide adequate production. Conductivity must also be high enough to enable this production.

Wellbores previously completed with the P-n-P technique in Fayette County took an average of five days. These wells contained 15 to 20 fracture stages, using a fracture design similar to the subject well. The challenge of reducing completion cycle time was seen as an opportunity to improve efficiency and well economics. However, production must not be sacrificed. CMSS was employed to evaluate whether the technique could achieve both goals. Additional challenges for the completion design were to:

- Provide adequate stimulation to the reservoir as evidenced by production.

Minimize completion time by improving efficiency.

- Mitigate completion risk from stuck frac plugs.

- Place proppant with adequate conductivity for liquid hydrocarbon production.

- Evaluate CMSS completion strategy and production results.

- Quantify lessons learned for continual improvement.

The purpose of this case study was to evaluate the CMSS technology compared to P-n-P, based primarily on three criteria, including: 1) reduction in total completion cycle time, 2) elimination of non-productive time (NPT) during the completion phase, and 3) achieving production comparable to offset wells.

COMPLETION STRATEGY

The case study well was to be drilled, for the operator, within the Eagle Ford shale play, but in a different field from previous wells. Even though this was a new area, CMSS technology was proposed for the 16-stage fracture completion, to improve efficiency. The CMSS would be run on a long string of production casing and cemented in place, in the same way as in P-n-P wellbores. A similar stimulation design would be used to provide the best comparison of completion efficiency to wellbores that had previously used P-n-P. Offset well production would also need to be considered, instead of using previous well production for analysis, due to the fact that this was a different county than in previous efforts.

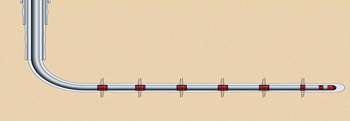

|

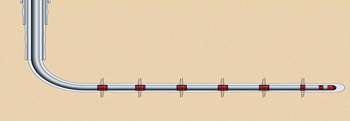

| Fig. 3. The opening of the CMSS and composite frac ball diverting fluid flow are illustrated. |

|

CMSS technology was selected, because it consists of multi-stage fracturing sleeves that are activated from the surface, thus removing the need for wireline intervention. CMSS uses a landing baffle and a composite frac ball, which are released remotely into the fluid stream at the wellhead. The composite frac ball travels in the fluid stream and seats itself on the corresponding landing baffle in the target CMSS. Increased pressure opens the CMSS, and the composite frac ball diverts fluid flow through ports in the outer casing of the sleeve and allows stimulation to occur, Fig. 3. The composite frac ball isolates the target CMSS from any stages that had been previously fractured.

In the subject well, graduated frac ball and baffle sizes were used, starting smallest at the toe of the wellbore, and continually increasing in size as distribution moved toward the heel. This allowed for numerous stages to be run in a single wellbore and all remotely actuated from surface. A hydraulically actuated toe sleeve was used to provide a flow path to pump the frac balls to the target sleeves, and to pump the first fracture stage. This tool works from absolute or total pressure (hydrostatic plus applied), and was shear-pinned-to-open based on the pressures that the tool would encounter during the cement job.

|

| Fig. 4. This example shows a CMSS completion cemented in place. |

|

The CMSS components were cemented in place using acid-soluble cement, which assisted with fracture creation efficiency, Fig. 4. The acid-soluble cement can be up to 90% dissolved by acid prior to the stimulation treatment, thereby reducing near-wellbore tortuosity. An optimized ball dropping procedure was also used that allowed for pressure indication of sleeve opening at the surface, reduced over-displacement of the previous fracture stages, and enabled placement of the acid adjacent to the sleeve ports just prior to opening of the target CMSS. Additionally, a flexible wiper dart system was used to allow effective removal of cement from the production casing during the cement job. These processes and tools assisted with the elimination of NPT during the completion cycle of the subject well.

WELL AND FRACTURE STIMULATION DESIGN

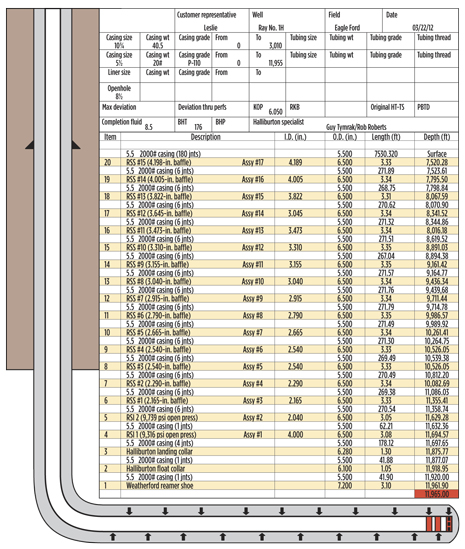

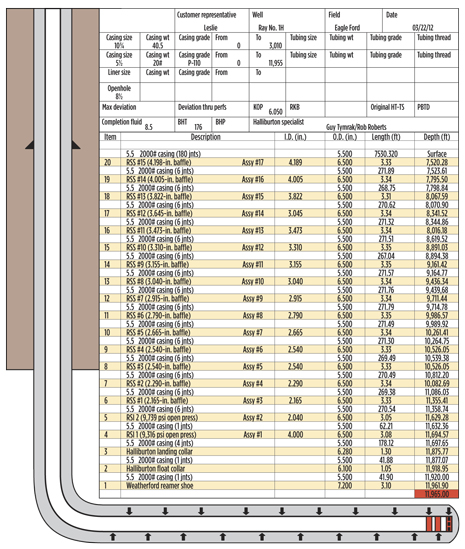

The subject well, which was similar to most Eagle Ford shale wells (Fig. 5), consisted of deep-set, 10¾-in. surface casing at 3,010 ft, MD, which was cemented back to surface with conventional cement slurry. The production casing string consisted of a long string of 5½-in. casing, with 16 CMSS sleeves at equal spacing, set at a depth of 11,965 ft, MD. The production string was cemented back to surface with conventional lead cement slurry and an acid-soluble tail cement slurry to isolate the lateral section, which totaled 5,913 ft. This was done inside an 8½-in. open hole section drilled from 3,010 ft, MD, to 11,965 ft, MD, below the surface casing string. A proprietary gelled cement inhibition fluid was used for displacement as insurance, in case of any residual cement.

|

| Fig. 5. Completion diagram provides details of CMSS components and their location in the subject well. |

|

The well was completed using 15 stages of CMSS to fracture stimulate the entire lateral section. Some 3.8 million lb of proppant with 2,901,000 gal of fluid were used to fracture stimulate the wellbore, averaging 54 bbl per minute (bpm). The 16-stage stimulation operation was completed in 24 hr with continuous pumping, compared to an average of three days for P-n-P stimulation and five days for previous wells in the county. As discussed below, the well’s production was comparable to that of offset wells, thus proving the technique viable for this type of oil shale formation.

|

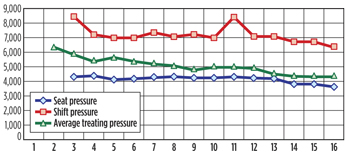

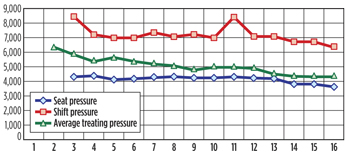

| Fig. 6. Frac ball landing, and shifting pressures that occurred during stimulation operations. |

|

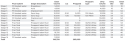

| Table 1. Treatment schedule for stages 1 through 4. |

|

|

| Table 2. Treatment schedule for stages 5 through 16. |

|

|

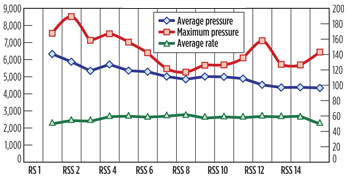

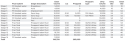

The stimulation design for the subject well called for 16 fracture stages to be pumped down the 5-½-in. production casing through the CMSS. The total treated interval was from 7,522 ft, MD, to 11,695 ft, MD. This was done with a conventional fluid system utilizing treated water and three different proppant types (100 Mesh, 30/50 Premium White, and 20/40 Premium White). Tables 1 and 2 illustrate the treatment schedule for the subject well. Also captured were sleeve shifting pressures, average treating pressures and amount of fluid over- or under-calculated displacement to land each composite frac ball. This information can be found in Table 3 and Fig. 6.

| Table 3. Planned frac ball landing details. |

|

.gif)

|

|

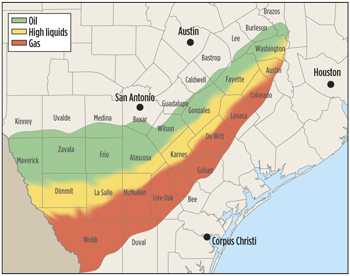

| Fig. 7. Stimulation pressures recorded for each stage. |

|

| Table 4. Times required for completion of each stage. |

|

|

A comparison of treating pressure used in fracturing the subject well is given in Fig. 7. This information shows the variability in the formation across the lateral section, as evidenced by the maximum recorded treating pressure. Table 4 catalogues the completion time for each of the stages on the subject well. The hydraulic sleeve at the toe of the wellbore was skipped and not fractured. The average pump time per stage was 1.6 hr for the CMSS, with an average of 240,000 lb of proppant being pumped per stage. Only 5.4 hr of time, on location, was spent in non-fracturing operations. This was due to pump maintenance and waiting to get additional materials to location. Total pumping time for the 15 fracture stages was 24.1 hr. This was an estimated 66% faster than the estimated time to complete a P-n-P job for the well.

PRODUCTION RESULTS

The subject well had the expected initial production after all of the CMSS stages were fracture stimulated, according to the stimulation design. For evaluation purposes, offset wells in the immediate area were examined and used to compare production results. Production levels from the subject well were compared to similarly designed wellbores in the immediate area, which allowed for the CMSS technique to be evaluated.

The subject well illustrates how the CMSS technology was employed to improve completion efficiency while eliminating NPT and still providing adequate well production. From the stimulation plots and completion time tables, it can be seen that CMSS drastically improved efficiency of the fracture stimulation delivery to the reservoir. Additionally, the processes assisted with reducing NPT, providing added efficiency increases. Efficiency gain was estimated at 66%, which is a two-day reduction in completion time over the previously employed P-n-P completion method.

Well economics were improved by lowering the cost per BOE, since production levels were maintained, and time on location was reduced. The comparison of production results of the subject well to offset wells showed that the goals were met, since production was equivalent. Overall, this evaluation proved CMSS technology was a significantly more efficient way to deliver the fracture stimulation treatment into the reservoir without affecting overall production. This reduced cost per BOE was due to direct savings from the improved completion cycle and decreased time spent delivering the well to production. The CMSS process has proven to be a viable alternative to P-n-P. It can be employed in the oil window of the Eagle Ford shale to maximize completion efficiency and reduce operator completion cost. Based on these findings, the operator has continued to use CMSS technology in additional Eagle Ford asset developments.

ACKNOWLEDGMENTS

1 Ferguson, K.; C. Thomas; B. Wellhoefer; S. Ingram, and M. Montes; “Cementing sleeve fracture completion in Eagle Ford shale will forever change the delivery of hydraulic fracturing,” SPE paper 158490, SPE Annual Technical Conference and Exhibition, San Antonio, Texas, Oct. 8–10, 2012.

REFERENCES

1 Ferguson, K.; C. Thomas; B. Wellhoefer; S. Ingram, and M. Montes; “Cementing sleeve fracture completion in Eagle Ford shale will forever change the delivery of hydraulic fracturing,” SPE paper 158490, SPE Annual Technical Conference and Exhibition, San Antonio, Texas, Oct. 8–10, 2012.

|

.gif)