BEATRÍZ VELEZ, WILLIAM CHARRY, ANKER DUARTE, JOHN RUBIANO, HERNANDO TRUJILLO and JOSE ALDEMAR TENGONO, Hocol; DARWIN FLOREZ, XIMENA GUERRERO, CLAUDIA NAVARRO and NICOLAS LOPEZ, Schlumberger

|

| Hocol (a subsidiary of Ecopetrol) rigs up to execute their next openhole gravel pack with ICDs, a technique now common in the Ocelote field in Colombia, where productivity and water encroachment control have been enhanced. |

|

Ocelote field in the Llanos foreland basin is Colombia’s most prolific hydrocarbon basin. A wildcat well in the field confirmed a monocline structure oriented in a northeast/southwest direction, developed in the footwall of the normal antithetic Guarrojo fault.

The main production interval is the Carbonera C7 formation, which produces 24° API oil. The formation has been interpreted initially as fluvial channel deposits associated with a broad shaly floodplain and highly unconsolidated sandstone.

In general terms, the Carbonera C7 formation consists of a monoclonal fault. The source rock is the Gacheta (Cretaceous), which is surrounded by black shales that are rich in organic matter.

Reservoir properties of the formation include a pressure of 1,643 psi and an average temperature of 173°F. Average porosity of the reservoir is 20%, and the average permeability fluctuates between 800 and 1,500 md. Water salinity is 100 to 150 ppm. The reservoir is fueled by a strong aquifer, and high water encroachment is expected within weeks of drilling a well.

COMPLETIONS METHODOLOGY

During development of Ocelote field, different technologies and techniques were used to address sand production issues within the Carbonera C7 formation.

The high heterogeneity of the formation sand, combined with the sand particle distribution, dictated that openhole gravel pack was the most favorable, effective technique for sand management in the field. Since implementation, no sand production has been experienced in any of the completed wells, and production potential has been exceeded in all the wells with lower drawdown applied. Once the sand control issues were addressed, Hocol decided to tackle the problems created by early water breakthrough and high water cut.

The reservoir has a full water drive producing mechanism that generates a fast increase in water production, which affects oil recovery and reduces well life. Most of the horizontal wells have shown a water cut of 90%, or more, in the first stages of production, providing an opportunity to develop a new completion approach that addressed sand control and water production, while also improving reservoir productivity by delaying water coning and breakthrough.

The entire completion architecture of the gravel-packed wells in Ocelote field included the openhole gravel pack assembly as its lower completion. In the upper completion section, an electrical submersible pump and a Y-manifold tool were implemented.

GRAVEL PACK DESIGN

The more extensive use and integration of simulators were crucial in optimizing and designing the best completion strategy for Ocelote field. The simulations provided a means for integrating the information from logs with reservoir parameters, such as permeability and pressure, in addition to a completion design that allowed for the evaluation of washout, severe doglegs in the openhole section and critical return rates.

The simulation’s critical parameters—fluid type, sand size, pumping rate, leak-off, return rate to surface and bottomhole assembly (BHA) hardware—showed how each parameter worked in different situations, and what the expected results could be in packing efficiency.

The simulator was integrated with the acquisition software in real time, and it was adjusted with the prior circulation test. For this application, the use of flowrate sensors in the return line was important to quantify the return rates, and to have a better approximation of the well status before and during the job.

A new tool string design was implemented earlier in the campaign, and new functionalities in the service tool were incorporated to prevent pre-setting, true swab prevention capabilities and wash-down capability. A new screen construction was also implemented.

The new gravel pack service tool selected maintains hydrostatic balance during all critical operations of the gravel pack. In addition, the tool provided washdown capabilities in positive tool positioning indication. The tool’s flow geometry was optimized to reduce the circulating pressure during the gravel pack, thus improving the likelihood of completing the gravel pack operation successfully. New, premium, sintered mesh screens were designed to optimize the number of base pipe perforations, the drainage layers, the design of the filtering media and high-flow shroud, to evenly distribute flowrates across the full area of the screen.

NEW ICD DESIGN

ICDs enable the balancing of flow across the entire horizontal section, to ensure even reservoir flow and a uniform production profile by applying adaptive flow restriction on high-flowrate zones. At the same time, low-production zones can be stimulated to mitigate early water conning, minimize water breakthrough tendency, achieve efficient areal draining, increase recoverable reserves and minimize the risk of bypassing reserves in the reservoir.

The benefits of horizontal gravel packs are achieved by integrating both techniques in one innovative, gravel-packed ICD completion. The new gravel-packed ICD string can be pulled out of hole, after completion if needed, to change nozzle distribution to suit reservoir changes.

Stand-alone screen (SAS) completions in the horizontal section were previously used in the field (Ocelote 3 and Ocelote 5). Because of sand particle distribution (uniformity coefficient and sorting coefficient) in Carbonera C7, these completions promptly suffered screen plugging that led to a low productivity index (PI).

It was necessary to gravel pack the wells, but achieving a successful, openhole gravel pack is dependent upon attaining a percentage of returns of no less than 90%, to establish sand dunes and alpha/beta waves. By incorporating a gravel pack and an ICD string, the expected results would reflect the best of both techniques.

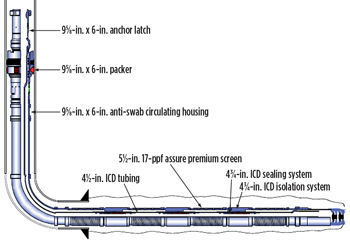

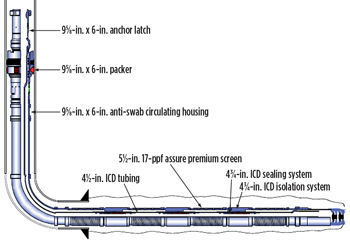

To perform gravel packing in the selected wells, a 5½-in., 17-ppf, 250-microns screen was selected to allow for placement of ICD tubing, with the ICD nozzles inside 4½-in. flush joints.

To compartmentalize the reservoir, a 4¾-in. inner diameter (ID) ICD isolation system was placed between the screens. In the internal string, a 4¾-in. outer diameter (OD) ICD sealing system was developed specially for this application.

Figure 1 shows the most common setup, which includes a series of short polished bore receptacles (PBR) run with the screens, to complement the internal sealing system and not compromise the gravel pack’s integrity. Figure 1 also shows the ICD nozzles incorporated inside the 4½-in. tubing and the seal assemblies that complement the internal isolation system.

|

| Fig. 1. Schematic of the 5½-in. gravel pack assembly, including the 4½-in. ICD internal tubing and internal isolation system. |

|

Four wells were selected as the pilots for new technology: Ocelote 32H, Ocelote 33H, Ocelote SW8H and Ocelote 103H.

The first use of the horizontal gravel-packed ICD technique was with Ocelote 33H, with 1,144 ft of horizontal section. The well was completed using a 5½-in. screen and three ICD isolation systems to compartmentalize the well.

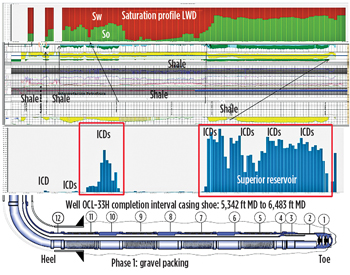

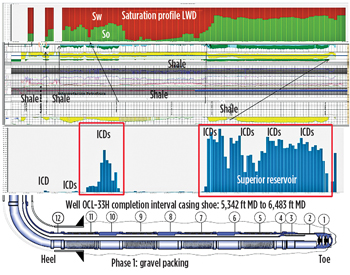

The gravel pack was completed with 100% packing efficiency. The localization of isolation systems was selected after calibrating logging-while-drilling (LWD) data and after-drilling petrophysical information, to maximize the selection and application of the ICDs with better productive potential, as shown in Fig. 2.

|

| Fig. 2. Gravel-packed ICD completion design matching saturation and permeability profiles for Ocelote 33H. |

|

Production scenarios for this well, and others that implemented the gravel-packed ICD setup, were simulated using ICD placement and simulation software based on fluid properties, rock properties and initial reservoir pressure to place the internal nozzle-based ICD string.

The nozzle-based ICD internal string was run in-hole two weeks after completing the well, and production began two days later.

The second selected well was Ocelote 32H with 1,100 ft of horizontal section. This well was completed with a 5½-in. screen and six ICD isolation systems placed to compartmentalize the well. The gravel pack was completed with 100% packing efficiency.

The placement of ICDs was done following the same procedure used in the first well. The nozzle-based ICD internal string was run in hole two weeks after the initial completion and production began two days later.

Similar procedures were carried out on the third well, the Ocelote SW8H, with 1,075 ft of horizontal section, and Ocelote 103H, with 813 ft of horizontal section.

PRODUCTION PERFORMANCE ANALYSIS

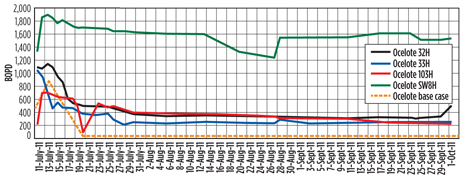

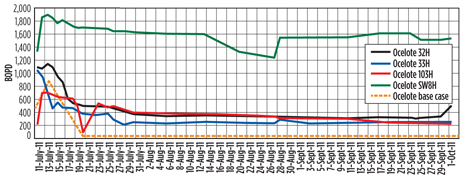

To evaluate the production performance of the selected wells, the production data were plotted and compared to identify any existing trends. Figure 3 shows the combined production curves from the four wells installed with graveled-packed ICDs, and the base-case well in the field.

|

| Fig. 3. Production curves for the Ocelote base-case well, and the four wells completed with gravel-packed ICD isolation systems. |

|

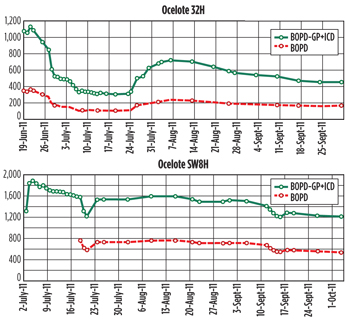

Based on the production curves, Ocelote SW8H and Ocelote 32H were chosen to simulate a scenario without ICDs, so that a comparison of production, with and without the gravel-packed ICDs, could be conducted.

To evaluate the true performance of the gravel-packed ICD, a scenario without ICD (only gravel pack) was also simulated, and the real production data were input into a hydraulic simulator, and then calibrated with the input of Pr, Kv, Kh, So, Sw. Additional reference data were taken from the Ocelote base-case well to validate the accuracy of the results. Uncertainty was low in well sedimentology, petrophysical properties and geological structures, while uncertainty about the accuracy of the fluid properties was high.

Variations in saturation values (So, Sw) to match the real production data provided a match point to simulate a scenario without ICD. The hydraulic simulator generated match points that were plotted as curves, by which real production and production without ICD could be compared.

The results showed an effective basic solids and water (BSW) reduction in both cases. For example, by Oct. 3, 2011, the real BSW in Ocelote SW8H was 32% with ICDs, and the BSW calculated without ICDs was 69%. In Ocelote 32H, by Oct. 1, 2011, the real BSW was 87%, and the BSW calculated without ICDs was 95%. All wells in the field, prior to the implementation of gravel-packed ICDs, were showing real BSW over 90% within the first 30 to 45 days after completion.

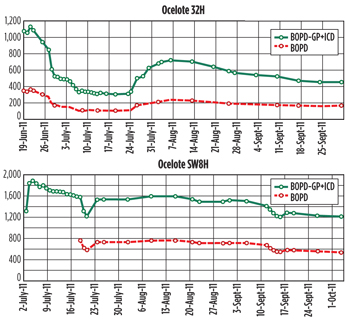

As regards oil production, the results show better performance with ICDs, Fig. 4. By Oct. 3, 2011, the oil production from Ocelote SW8H was 1,230 bopd, and the production calculated without the ICD was 547 bopd. Similarly, by Oct. 1, 2011, oil production from Ocelote 32H was 456 bopd. Without using ICDs, production for the well would have been 169 bopd.

|

| Fig. 4. Oil production comparison for Ocelote 32H and Ocelote SW8H. |

|

The results proved that the nozzle-based, gravel-packed ICDs worked properly and balanced the flow across the horizontal section. Additionally, results showed that the novel approach increased oil sweep in the reservoir, and reduced water breakthrough and conning effect, while delivering 100% gravel pack efficiency and sand-free production.

The design of the entire gravel pack completion allowed for the inner ICD string to be retrievable, providing the flexibility for reconfiguration of the nozzles and the spacing out of the ICDs.

This design improved the efficiency of the ICD completion and delivered even further productivity to individual wells or entire fields. In the case of Hocol, the plan was to retrieve, reconfigure and run the ICD strings again in the next stage of field development.

NEW PRODUCTION LOGGING APPROACH

In the Ocelote wells, the Schlumberger horizontal and deviated well production logging system that was used incorporated multiple spinners covering the entire cross-section of the pipe. The logging system measured fluid velocity at five points across the vertical diameter of the well.

Electrical and optical probes positioned in close proximity to the spinners gave an estimation of gas, water and oil hold-up. Additional challenges emerged, when well completions included screens, or when other types of flow in the annulus space were suspected (e.g. cement channeling or annular production flow). To obtain an accurate flow profile, uncertainties, such as variable hole ID and screen decentralization, had to be overcome.

It was, therefore, necessary to combine measurements that covered both the inside of the completion, and the annular space between the tubular and the formation. Such an approach was obtained by running the horizontal well production logging tool, combined with a reservoir saturation tool.

Two applications of the reservoir saturation tool were used in this case: a three-phase fluid holdup log from pulsed neutron measurements, and a water flow log. Unlike other applications, the tool was run centralized, and measurements of water velocity and phase holdup were obtained inside the wellbore (both annular and pipe) by the acquisition of station logs.

The general logging program for the wells included production logging tool passes with the well shut-in, and with the well flowing at a stabilized flowrate; water flow log stations for water velocity measurements; and continuous pass for acquisition of three-phase fluid holdup data.

A combination of the production logging and reservoir saturation tools was run in the four wells completed with gravel-packed ICDs in open holes. The internal ICD system was retrieved prior to the logging run. The same log was run in wells with an arrangement of ICDs, and through the upper completion.

Production rates for the wells in the campaign ranged from 2,800 to 3,500 bfpd, with a water cut between 92% and 96%. Produced oil had 23°-to-25° API gravity, and production water had salinity close to 200 ppm. In this environment, water holdup was measured with optical probes, using the previously described methodology.

CONCLUSIONS

In most of the cases, oil production was found to come from the toe of the wells in the B1 sand. Oil production was associated with a significant water cut from startup. Intervals of 100% water cut production were found along the horizontal section in the wells logged, also in the B1 sand.

Effective production length in the logged wells was reduced to the B1 sand portion. In some cases, this producing zone was found to be as low as 400 ft, out of 1,000 ft of total horizontal length. None of the wells logged showed any production contribution from along the horizontal section.

In terms of fluid production, the wells completed with the ICD system responded positively in terms of water cut reduction, which proved the system’s efficiency.

The project shows an effective integration of nozzle-based ICD technology with horizontal gravel-pack completions, to improve well productivity in applications where the SAS technique is not advisable.

An integrated sand management approach was an effective solution in the successful completion of the four wells in this project, resulting in 100% packing efficiency and installation of the nozzle-based ICD, with no quality, health, safety or environmental issues.

The group of depleted wells benefited when using the ICD, reducing BSW by 7% to 8%. The impact was greater in Ocelote SW8H, which experienced a 37% reduction of BSW.

The gravel-packed ICD completion showed benefits over horizontal openhole gravel-pack systems, in terms of BSW reduction and oil recovery, translating to improved field productivity and increased well longevity. These gravel-packed ICDs are the first true retrievable ICD system available for wells requiring inflow control and gravel packing.

|

The author

BEATRÍZ VELEZ COLMENARES is a development geologist with experience in basin evaluation studies, static model generation from 3D seismic interpretation and reservoir characterization integrating surface geology, well log, core, petrophysical, biostratigraphic, petrographic, seismic, production and pressure information and data; completions recommendations, development plans, risk assessment and classification perspective, effective reserve development and E&P cycle optimization. She graduated from the Universidad Industrial de Santander, Colombia, in 1999, and has been with the Hocol production team since 2006.

WILLIAM MAURICIO CHARRY is a production technology engineer for Hocol, working mainly on field development technology. He graduated with a petroleum engineering degree from the Surcolombiana University (USCO), Colombia, and has been part of Hocol since 2006.

ANKER DUARTE is working as a reservoir engineer at Ocelote field for Hocol, mainly executing the field development plan, overseeing the reservoir and continuously looking for opportunities to increase production using analytical and numerical models. He has a BS degree from the Universidad Industrial de Santander, Colombia, and has 10 years of experience in the petroleum industry.

JOHN RUBIANO is a petroleum engineer with 13 years of experience in the oil and gas industry. Mr. Rubiano is working with Hocol in Colombia as a completions and workover engineer, and sand control specialist.

HERNANDO TRUJILLO is a petroleum engineer with more than 23 years of experience working in the oil and gas industry. Mr. Trujillo is working with Hocol in Colombia as a senior operations engineer, and completion, workover and sand control specialist.

ALDEMAR TENGONO is a petroleum engineer with more than 17 years of experience working in the oil and gas industry. Mr. Tengono is working with Hocol in Colombia as a senior completion and workover engineer, and sand control and heavy oil specialist.

DARWIN FLOREZ has worked in the oil and gas industry for more than 13 years, all with Schlumberger. Mr. Florez is in sand control technical support for Colombia, working mainly on sand control tools, and complex lower and upper completion designs for different operators.

XIMENA GUERRERO is a petroleum engineer with nine years of experience in the reservoir engineering environment. Ms. Guerrero supports the completions segment in Schlumberger as reservoir domain champion in charge of developing, from the technical side, new and complex completions technologies. She has extensive experience in production logging, and pressure and fluids analysis.

CLAUDIA NAVARRO is Schlumberger’s fracturing technical engineer for northeastern Brazil, working mainly with fracturing and stimulation applications on land for tight and shale formations. Previously, she worked in Colombia as technical support for fracturing and sand control. She graduated with a petroleum engineering degree from the Universidad America, Colombia, and has been part of Schlumberger Well Services since 2004.

NICOLAS LOPEZ is the global business development manager for sand control, screens and ICDs at Schlumberger, based in Houston. He has more than 15 years of industry experience, including worldwide assignments in technical and management roles. Mr. Lopez has been involved in the design of completions and sand control projects around the world, and new technology innovation and commercialization of products at Schlumberger. He holds BS degrees from Texas A&M University, an MBA degree from the ITESM in Mexico, and an MS degree in petroleum engineering from Herriot Watt University.

|

|