|

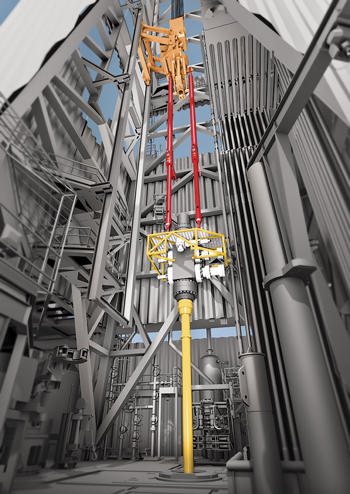

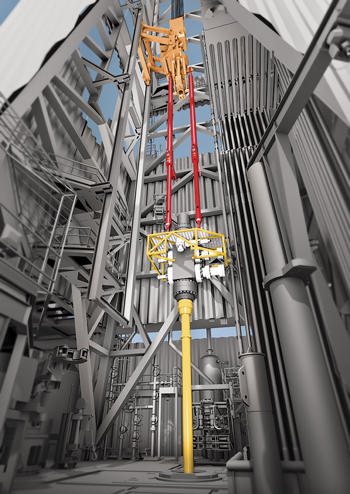

| The Weak Link Bail is designed to improve the safety of completions and workover operations worldwide. |

|

The catastrophic failure of a riser or landing string inside the marine riser of a floating mobile offshore drilling unit (MODU) is a real but not widely acknowledged hazard. However good their design, compensator systems are all subject to the risk of failure.

One potential significant failure is “lock-up,” where the work string effectively becomes rigidly attached to the blocks. If it is pinned to the seabed at the same time, then even a comparatively modest heave motion can transmit significant tensile forces to the landing string tubular, potentially causing tensile failure.

The resultant release of energy can result in major damage to equipment in the derrick and to significant dropped objects, including a top drive. Should this event occur when there are hydrocarbons present in the work string—for instance, during a well test or completion unloading operation—the risk of fire or explosion is obvious. This hazard can readily be categorized as a Major Accident Hazard (MAH) with the potential for many fatalities.

Cutting the risks. Compensator failures are not rare in our industry. If they occur during drilling activity, when the work string is not pinned to bottom, there are often no significant consequences, other than some down time while the system is repaired. Such events are not well catalogued, so it is difficult to quantify their frequency.

However, SPE paper 59216 catalogues three such events, which occurred during well test or completion operations in the North Sea during the 1990s, and which could have resulted in multiple fatalities and serious injuries. One of these events resulted in severe damage to derrick equipment. Most operators can cite some instance of direct or indirect experience where compensator failure has occurred, sometimes causing significant damage.

The reality is that compensators are not completely reliable, whether using an active heave drawworks system or the more traditional, passive heave compensator. There is a great deal of complexity in these systems, which rely on the expertise of those maintaining and operating them to function reliably.

Engineered solutions. To address the risk of compensator failure, James Fisher offers two engineered solutions, produced subject to the company’s usual design verification processes, and fully compliant with recognized industry codes.

The Weak Link Bail is a shearable set of telescopic bail arms, available since 2005, which has been deployed successfully in North Sea oil and gas operations, where there are several units in use. The bail arms are pinned in mid-stroke, so that, should a compensator lock-up occur, the pins shear at a selected value below the tensile strength of the work string. and the arms telescope out to compensate for heave stretch. The design of the system incorporates a reset feature so that the driller can readily regain control of the work string.

The Safety Slick Joint is an alternative solution that is well-suited to many well test applications. The safety slick joint installed below a subsea test tree incorporates a feature that allows work string movement, subject to a pre-defined shear load in the event of compensator lock-up. The device is deceptively simple, requiring no seals or sophisticated components, and will reliably prevent tensile failure of the landing string.

In addition to the above, James Fisher also recently announced its intention to offer an active secondary compensator system that will further improve safety. These simple, yet highly effective technologies represent proven solutions that help protect against the risk of excessive downtime, damage to high-value equipment and injury to the drilling workforce caused by compensator lock-up.

|

The author

RITA PAINTER is business development manager at James Fisher and Sons plc. She is a metallurgist, who has spent most of her career in the mechanical engineering industries, working in Latin America, the Caspian, India and Europe. R.Painter@James-Fisher.co.uk. |

|