The P-63 Floating Production Storage and Offloading (FPSO) vessel, developed specifically to work in Brazil’s offshore Papa Terra oil field, is unique in that it will be the first FPSO vessel to utilize gas-fueled engines to produce more than 100 MW of power. The contract to supply the three main power modules to achieve this demanding output was awarded to Wärtsilä. This also includes commissioning, start-up and operational supervision.

|

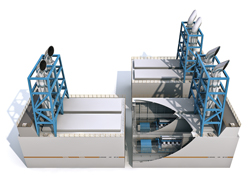

| Fig. 1. The P-63 FPSO will be equipped with three main power modules, each of which includes two Wärtsilä 50DF dual-fuel engines, alternators and auxiliary equipment. Photo courtesy of Wärtsilä. |

|

Wärtsilä 50DF dual-fuel engines were selected as the most suitable solution for the application, with each power module including two 18-cylinder 50DF engines in V-configuration. The alternators and auxiliary equipment are also installed within the modules, Fig. 1.

The full 100% load tests of the engines for the P-63 FPSO were completed successfully at the Cosco shipyard in Dalian, China, where conversion work to the vessel was carried out.

Wärtsilä’s dual-fuel technology was chosen because of its ability to allow various types of fuel to be used. In this case, the engines can utilize treated well gas and treated crude, as well as MDO (marine diesel oil). It means that the FPSO needs virtually no fuel from the mainland, thereby reducing operational costs. Furthermore, by running on gas, emissions of CO2 will be significantly lower than those from conventional technologies. It is estimated that carbon emissions will decrease by as much as 93,000 t/year.

Because of the extreme water depth, and the high viscosity and low API of the crude, this offshore project is one of the most complex subsea developments ever executed in Brazil. It requires the state-of-the-art technology used to be proven, reliable and well-supported to ensure the project’s long-term success. So Wärtsilä’s integrated turnkey power solution had to meet all these criteria, while, at the same time, achieving the breakthrough performance level of providing more than 100 MW of installed gas engine power.

|

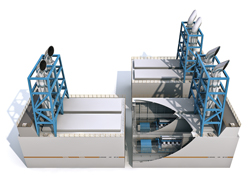

| Fig. 1. The P-63 FPSO is designed to operate for 25 years without going to drydock, making highly reliable engines essential. Photo courtesy of Wärtsilä/Juha Nurmi. |

|

The converted FPSO was delivered by the Cosco Dalian yard on Nov. 15, 2012. The vessel is designed to operate for 25 years without going to drydock, hence the need for reliability and efficiency in all the installations onboard, especially the power modules, Fig. 2. At present, it is in Rio Grande, Brazil, where finalization work is being carried out.

IMPROVED PERFORMANCE

Wärtsilä has been at the forefront in developing dual-fuel engine technology. The technology behind its range of four-stroke, dual-fuel engines—the Wärtsilä 50DF, Wärtsilä 34DF and Wärtsilä 20DF—emphasizes high efficiency and low exhaust emissions. The Wärtsilä 50DF engine is one of the company’s most successful products. It has been used in marine applications since 2006, when dual-fuel propulsion was introduced. Its efficiency can exceed 48%, which is probably a record at this time.

The essential concept of dual-fuel technology is to provide a means of utilizing natural gas as fuel, while retaining the ability to switch to liquid fuels, as needed. This switch between fuel types can be made automatically and without loss of operating power. By applying modern electronic combustion control, Wärtsilä has paved the way for improved performance and greater reliability of gas engines, combining different technologies to produce a new, viable solution. It is this flexibility in fuel choice, coupled with the environmental benefits of using gas as fuel, which is crucial to the operating profile of the P-63.

Development work on the DF technology continues, and future benefits can be clearly identified. For example, when incorporated into the design of the ship’s power system, the use of dual-fuel generating sets eliminates the need for additional essential gensets. Furthermore, for newbuild FPSOs or LNG carriers, all power generation equipment can be kept within the hull, thereby reducing costs and freeing up topside space.

To date, Wärtsilä has sold more than 700 of its dual-fuel engines and has accumulated well over 7 million running hours of experience with this technology.

Papa Terra development pushes ahead

Papa Terra heavy crude oil field, off the coast of Rio de Janeiro, Brazil, is estimated to contain between 700 MM and 1.0 billion boe and, as such, is a hugely important resource. However, since being discovered in 2003, its development has been hindered by the extreme water depth, and by the high viscosity and low API of the crude. In fact, the field lay dormant for two years because of these factors.

Now things are moving ahead, thanks largely to a field development concept that involves a P-61 tension-leg wellhead platform coupled to a new P-63 FPSO vessel. The contract for the P-63 FPSO was signed in January 2010 between Norway-based BW Offshore and its consortium partner, Brazilian industrial group QUIP, and the Papa Terra BV Joint Venture partners, Petrobras and Chevron.

The 323,000-dwt ultra-large crude carrier (ULCC) BW Nisa, built in 1983, has been converted for the P-63 project. BW Offshore has been responsible for the marine scope of the conversion, including the hull, offloading systems and mooring equipment. QUIP provided the topside facilities to process approximately 140,000 bpd of crude oil, 35 MMcfgd and 325,000 bpd of produced water. Facilities to inject some 340,000 bpd of seawater have also been included. QUIP and BW Offshore will jointly operate the FPSO for a period of three years, with a gradual handover to Petrobras.

|

The author

JEROEN VAN KEEP is business development manager, Offshore, at Wärtsilä. He is responsible for new projects in the offshore market, including diesel engines, power generation and distribution, automation and propulsion. He has co-authored papers on thruster condition monitoring, vessel automation systems and optimizing power generation.

|

|