RENATO G. RAMOS, F. AGUILERA NAVEJA, GIOSWALD R. INCIARTE FERMIN, Pemex Exploration and Production; MARCO A. DOMINGUEZ, STEVEN M. ROSENBERG, Weatherford

Massive circulation loss and hole instability problems offshore Mexico were mitigated in a series of wells that incorporated liner drilling in their basis of design. Problems on two previous wells in the field had resulted in 55 days of nonproductive time (NPT) that cost an estimated $5.68 million. The drilling-with-liner (DWL) solution allowed the operator to reach the intended liner setting depths, eliminate contingency liners, and ultimately meet well construction objectives. Application of the technology over nine wells also allowed optimization of the liner drilling process for the specific application, including equipment selection, operations and results.

The key to success was the ability of liner drilling technology to isolate the loss and instability intervals. Lost circulation and wellbore instability problems, seen in conventionally drilled wells, were effectively mitigated with liner drilling. In addition, annular fluid management was enhanced by the narrow annular geometry created by liner drilling. Drilling operations were assisted by high torsional capacity and cyclic fatigue resistance achieved with a hydraulic liner system, as well as the effectiveness of drillable PDC casing bit technology in drilling the trouble sections.

EL ABRA CHALLENGE

|

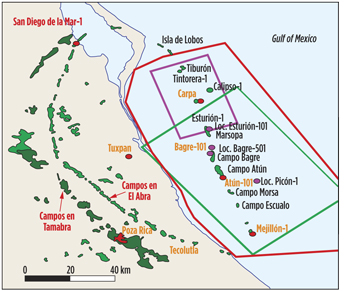

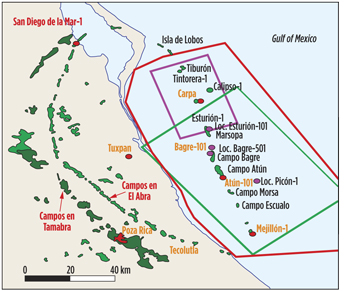

| Fig. 1. Pemex’s Carpa field is in the Gulf of Mexico offshore of northern Veracruz state. |

|

Pemex’s Carpa field is in the Golden Lane (Faja de Oro) area of the Gulf of Mexico offshore of northern Veracruz state, Fig. 1. The El Abra reservoir rock is a naturally fractured middle Cretaceous limestone capped by impervious Miocene shales. It was extensively eroded prior to Miocene age burial, and, as a result, the structural depth is very difficult to predict. This difficulty is compounded by the differential pressure between the overlying shale and the El Abra, which is the source of serious downhole problems, including severe lost circulation, stuck pipe, cave-ins and poor cement jobs.

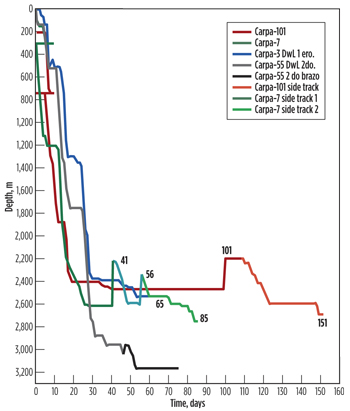

Two appraisal wells, the Carpa 101 and Carpa 7, experienced significant problems while drilling and required sidetracking to reach the El Abra. In the case of the Carpa 101, 7-in. casing was run and cemented at 7,865 ft. Drilling continued with a 5⅞-in. bit and 8.8-ppg mud. The top of the El Abra was reached at 7,960 ft, and drilling continued to 8,101 ft. A drillstem test (DST) was conducted, and no flow was observed.

A 5⅞-in. bit run to condition the hole met resistance at 7,875 ft, and the hole was reamed to total depth (TD) while fighting cave-ins and mud losses. A 3½-in. liner with inflatable packers was then run and set at 8,016 ft. No production was observed, and a 5⅞-in. sidetrack was initiated from the 7-in. casing at 7,209 ft. The sidetrack was drilled to 8,823 ft, and the well was successfully placed on production. In total, NPT drilling the El Abra accounted for 15 days and had an economic impact of $900,000.

In the Carpa 7 drilling operations, 13⅜-in. casing was run and cemented at 3,955 ft, and a 12¼-in. hole was drilled at 70° to 8,574 ft, using 10.3-ppg mud. At the top of the El Abra, total mud loss was experienced, and seawater was pumped to reestablish circulation. A trip into the hole met resistance, and several incidents of stuck pipe occurred until 8,085 ft, when the pipe got stuck again. Mud weight was increased to 10.7 ppg and the drill string was retrieved, but a fish was left in the hole. When the fish was recovered, a Tricone bit was run. It found resistance, particularly at the 8,091- to 8,144-ft interval. After several attempts to go deeper failed, a cement plug was set and a 12¼-in. sidetrack was drilled.

The sidetrack reached 8,515 ft—about 16 ft above the top of the El Abra formation. A short trip back to the casing shoe experienced 30,000-lb drag between 8,190 and 8,537 ft. Mud weight was increased slightly, and the bit was run to bottom. When attempting to pull out of the hole, 25,000-lb drag was experienced and a pressure build, followed by circulation loss, occurred. The pipe stuck and was eventually cut, leaving 154 ft of fish in the hole.

A cement plug was set above the fish, and a sidetrack was drilled. Because of the potential of circulation loss in the top of the El Abra and marl-related stability issues, the sidetrack was drilled to about 40 ft above the El Abra, and 9⅝-in. casing was run and cemented to 8,312 ft. An 8½-in. hole was drilled out of the 9⅝-in. casing shoe with a 8.7-lb mud to 8,528 ft at an inclination of 72°, where a 7-in. liner was set, and a 5⅞-in. hole was drilled to 9,020 ft TD.

NPT was also significant for the Carpa 7. The time spent fighting the El Abra accounted for 39.65 days and a fluid loss of 2,554 bbl, at a cost of $4.78 million. Experience drilling both wells made it clear that drilling the El Abra formation required finding a means of mitigating the circulation losses and instability that were causing so much NPT.

DWL EVALUATION

Alternative solutions were examined with several objectives in mind. Ultimately, the new approach had to minimize or eliminate NPT. Key goals included ensuring that the liner could be set as planned into the top of the El Abra, while isolating the overlying shale in a single hole section. In addition, it was important to achieve a competent cementing job that would eliminate the need for remedial cementing.

Offset well data were reviewed, including drilling, lithology, geological, bit records, and an analysis of NPT. The analysis found approximately 55 days of NPT were spent in the problem intervals of the Carpa 101 and Carpa 7 wells. Most of this was due to circulation losses, and the related hole instability encountered when attempting to identify the top of the El Abra.

Liner drilling offered several advantages that addressed the project objectives. The technique is effective in minimizing and eliminating lost circulation problems due, in part, to the smear effect, in which cuttings crushed in the narrow liner-wellbore annulus form an impermeable cake on the wellbore wall. The narrow annulus also results in higher fluid velocities that improve hole cleaning. Surge and swab problems related to pipe tripping are minimized, because the liner is drilled-in and cemented in a single trip. Once landed, the liner can be cemented almost immediately, which reduces or eliminates hole preparation.

To take full advantage of these capabilities, Weatherford’s DWL methods were incorporated in the well construction basis of design. The plans called for drilling the section into the top of the El Abra formation in two stages. A conventional directional drilling system, with continuous rotation, would be used to build a high-angle hole. After reaching a suitable depth determined by an on-site geologist, DWL would be used to drill the wellbore to the top of the El Abra, where the liner would be hung immediately and cemented in place.

EQUIPMENT SELECTION

|

| Fig. 2. Five-bladed PDC bits with 16-mm and 13-mm PDC cutters and tungsten carbide gauge protection helped achieve high-performance drilling with liner. |

|

Choice of equipment was critical to the success of the project, because of the long time that the liner and the liner hanging equipment would be exposed to the extreme loads and torques of the proposed DWL operation. Bit experience in the original wellbores led to the selection of 9⅝ × 12¼-in. and 7 × 8½-in., displaceable casing bits for the respective 9⅝-in. and 7-in. DWL operations. The five-bladed PDC bit designs, with respective 16-mm and 13-mm PDC cutters and tungsten carbide gauge protection, provided the appropriate cutting structure with the ability to perform in formations with unconfined compressive strengths up to 15,000 psi, Fig. 2. The gauge section design provided a back-reaming capability. The drillable bit is converted to a drillable casing shoe at TD, to enable drill-out with conventional PDC or roller cone drill bits. Drill-out is eased with drillable copper or ceramic nozzles that avoid the damage that conventional carbide nozzles can cause to the drill-out bit.

When TD is reached, a ball is dropped into the liner running string to block fluid flow through the drilling nozzles. The resulting hydraulic pressure shears pins and forces an inner piston downward. The piston displaces the bit’s steel blades and PDC cutting structure into the annulus, and exposes cementing-circulation ports. Once cementing is complete, the inner piston is drilled out, and the next hole section is drilled with the drill-out bit, without milling or additional trips.

A heavy-duty liner hanger system included a liner-top packer and tieback completion polished bore receptacle (PBR). These components were designed to suspend the liner load and seal the annulus after cementing operations, as well as to transmit the required torque and dynamic forces needed to drill the openhole section. A premium, hydraulic-set rotating liner hanger and top packer system, designed for deep, high-angle applications, were selected. The package provided the ability to support extended rotation periods and enable maximum workability during deployment.

Cementing equipment included a double-flapper float collar. It was strategically positioned in the shoe track to allow the passage of the 1¾-in. ball, dropped to activate the drill shoe displacement, and the 2⅛-in. OD ball to release the liner-setting tool. The float collar served two purposes: it acted as a mechanical well control barrier, similar to a drill pipe float valve in standard drilling operations; and it provided a one-way check valve system to retain the cement after placement. A landing collar located one joint above the float collar received the liner wiper plug at the end of the liner cement job.

DRILLING OPERATIONS

|

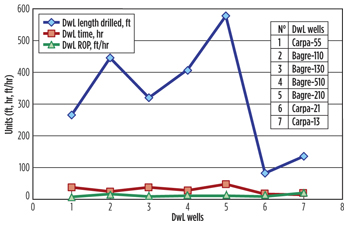

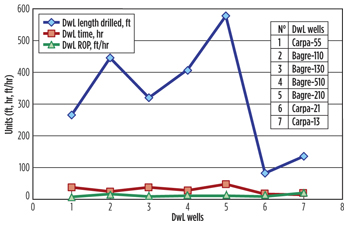

| Fig. 3. Ft/hr performance of the DWL wells. |

|

Nine wells were drilled in the Faja de Oro area using DWL technology—five in Carpa field and four in Bagre field, Fig.3. Standard drilling procedures were applied on each well to reach the geologist-selected point above the El Abra. At this point, the drillstring was pulled out of the hole (POOH), and drilling continued using DWL methods.

The first well, Carpa 3, was drilled with the objective of eliminating a contingency liner above the El Abra formation. A 12¼-in. vertical hole was drilled conventionally to 7,808 ft. The hole was conditioned, and the drill string was POOH. A 4,252-ft length of 9⅝-in., 53.5 lb/ft liner, equipped with a 12¼-in. casing bit, cementing float collar, and the 9⅝ × 13⅜-in. hydraulic liner hanger and compression-set packer, was run-in on drill pipe.

An additional 52 ft of 12¼-in. hole were drilled with the 9⅝-in. liner, cementing equipment was rigged up, and an activating ball was dropped and pumped to convert the casing bit and activate the liner hanger. The efforts failed, and eventually the bottomhole assembly (BHA) was POOH, and a full string of 9⅝-in. casing was run and cemented on bottom prior to drilling the El Abra.

In examining the liner drilling BHA, it was discovered that the flapper in the float collar had sheared off, and the activation ball was jammed, preventing the pressure build-up needed to convert the casing bit. While the issue was problematic, it was noteworthy that the DWL section was drilled without a problem.

With some modifications to procedures and equipment, a second well, Carpa 55, was drilled. The 12¼-in. hole was drilled conventionally to 9,452 ft at 75°. The drilling BHA was POOH, and 4,964 ft of 9⅝-in., 53.5-lb/ft liner were run in the well. As in the previous well, the assembly included a Defyer DPC casing bit, and hydraulic liner hanger system. A 9⅝ ×11⅞-in. centralizer was positioned 26 ft above the casing bit and, to help maintain hole angle, a 9⅝ × 12⅛-in centralizer was placed 22 ft higher in the hole.

An additional 266 ft of hole were drilled to 9,718 ft. The casing bit was successfully converted, and the liner hanger was set and the running tool released. The liner was then cemented in place, the packer set, excess cement above the packer was circulated out, and the drillstring was POOH. The DWL operations successfully stopped loss circulation problems.

The Bagre 110 was drilled, and 9⅝-in., 53.5-lb/ft casing was cemented at 4,265 ft. An 8½-in. hole was drilled conventionally to 8,776 ft. The well was reamed and conditioned, and 4,967 ft of 7-in., 29-lb/ft casing were run in the well. The string was equipped with a 7 × 8½-in. casing bit, and 7 × 9⅝-in. hydraulic liner system and compression set packer.

The liner was run in on drill pipe and reamed to bottom, and an additional 443 ft of 64–67°, 8½-in. hole were drilled with the 7-in. liner to a total depth of 9,219 ft. The setting ball was dropped to convert the bit and set the liner hanger, and the liner was cemented in place without incident. No instances of lost circulation were experienced.

Three additional Bagre wells (130, 510 and 210) were drilled in a similar manner to Bagre 110. A 7-in. liner was used to drill 322 to 577 ft of hole at angles from 72–75°. Setting depths ranged between 9,130 ft and 13,527 ft. The liners on each well were successfully set and cemented in place with negligible mud losses.

Significantly, Bagre 210 and 510 had extended-reach depths of 13,527 ft and 12,730 ft with a 75° angle, where the liner was landed. Mechanical friction-reducing tools were strategically positioned on the landing string, across the build section of the well. While torque was generally a little higher, no pack-offs or stall-outs were encountered.

For the next two wells, Carpa 13-H and 21-H, a 7-in. liner was drilled in, successfully hung off and cemented, and the liner packer was set. The hole angles were 73° and 75°. Both wells were drilled with little or no lost circulation.

On the Carpa 15-H, the 8½-in. hole was conventionally drilled to 8,854 ft. While running in hole with the 7-in. × 8½-in. DWL assembly, conditions required washing and reaming the liner in the existing 8½-in. hole. At 8,867 ft, MD, reaming parameters (flow, rotation and torque) were increased in an effort to ream the remaining open hole. An attempt to pick up the string only moved it 10 ft, presumably due to a tight hole, poor cleaning or hole collapse. Surface pressure was increased to 1,800 psi, which was higher than the liner hanger shear pin setting. It was determined that the hanger was activated, preventing weight from reaching the casing bit. Ultimately, the DWL string had to be pulled out of the well.

LINER DRILLING SOLUTIONS

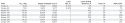

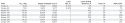

| Table 1. Forecast assumptions for liquids production in three key basins |

|

|

|

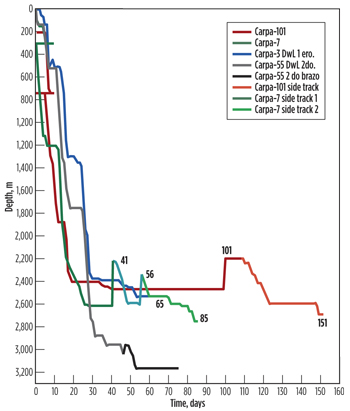

| Fig. 4. DWL achieved a drastic reduction in NPT and mud losses, and the elimination of contingency liners resulted in great improvements in drilling time. |

|

The principle of DWL technology worked very well in this difficult drilling environment. Apart from mechanical problems experienced on Carpa 3 and 15, the technology solved the problem of massive circulation and mud losses. It is noteworthy that the first well was drilled very conservatively with only 52 ft of new hole. As the operator became more comfortable with DWL, the lengths drilled increased to a maximum of 576 ft, Table 1. The use of DWL has resulted in a drastic reduction in NPT (Fig. 4)and mud losses in these wells, and the elimination of contingency liners resulted in great improvements in the economics of drilling and completing wells in the Faja de Oro’s El Abra formation.

|

The author

STEVE ROSENBERG is the global drilling reliability manager at Weatherford. Mr. Rosenberg has 25 years of experience in the oil and gas industry, previously holding drilling and production engineering positions with Diamond Offshore Team Solutions and Conoco. He holds BS degrees in petroleum engineering, from Mississippi State University, and biology, from St. Lawrence University in Canton, New York. |

|