|

ZILLUR RAHIM, HAMOUD AL-ANAZI and ADNAN AL-KANAAN, Saudi Aramco

|

| Saudi Aramco Gas Reservoir Management Division (GRMD) team members Alsana (left), Dr. Anazi, Dr. Kanaan (manager), Dr. Rahim and Sharif. |

|

The primary purpose of hydraulic fracturing is to enhance productivity. An unconventional gas reservoir will not produce unless long, conductive fractures are placed in the tight gas formation. A successful treatment will improve well production and sustainability; however, fracturing is never optimal, and the industry has been working on several fronts to obtain improved results. Some of these fronts include a complete change in the fluid system, such that the gel damage is reduced and the fluids pumped can be flowed back efficiently. The gel breaking agent is, therefore, an important ingredient, and the right amount and type are some of the key factors that help minimize proppant conductivity damage from gel residue. The proppant system and pump schedule have also been revised. These changes are intended to provide longer, more conductive fractures and reduce chances of premature screen-outs. This article focuses on best practices associated with gel and polymer systems, and the breaking agents. Examples from Saudi Arabia confirm the successes achieved through the identification of problems, and followed by remedial actions.

FRACTURE FLUIDS CHEMISTRY

Several major aspects need to be considered for the most appropriate fluid selection, to ensure good results after the fracture treatment. Most importantly, the fluid must be compatible with reservoir pressure-volume-temperature (PVT) properties, so that there remains no chance of creating formation damage. Other aspects to consider include:

- Control fluid loss and provide optimum fracture geometry.

- Have considerable viscosity to transport proppant at the designed concentration.

- Resist pressure and sheer degradation as the treatment progresses.

- Provide lower friction loss to reduce injection pressure.

- Include sufficient additives to control vital fluid properties, such as pH level and viscosity.

- Provide adequate, effective breaker systems to break the polymer gel, once treatment is complete and the fracture has closed.

- Provide higher regained permeability of the proppant pack.

Use of viscoelastic surfactant fluids (VES), a polymer-free, low surface tension system, is a good option in fracturing treatment. These fluids use surfactants with inorganic salts to create ordered structure, resulting in increased viscosity and elasticity.1 The two inherent shortcomings with other fluids, low viscosity at high temperatures, due to thermal thinning and lack of internal breaking mechanisms, are minimized in the new fluid formulation. These fluids are insensitive to salinity, compatible with N2 and CO2, and do not require clay control agents. The fluid does not form filter cake, therefore, there is no plugging of the formation, and the post-treatment retained permeability is high. Basically, VES uses surfactants in combination with inorganic salt to create ordered structures, which eventually results in increased viscosity and elasticity. The fluids tend to be shear‐degradable, but can transport proppant with lower loading, and without the comparable viscosity requirements of conventional fluids.

SHEAR AND TEMPERATURE TOLERANCE

While there is no single all-purpose-fit fluid, and every well must be evaluated for selecting the most appropriate fluid characteristics, the newer fluids, with fewer additives and a dual cross-linker (borate and zirconate) system, have achieved good results. Typically, the borate cross-linkers are shear-tolerant, but are affected by temperature. In contrast, the zirconate cross-linkers are temperature resistant, but shear-degradable. The dual cross-linker system, therefore, is considered to be an appropriate type of fluid to use.

GEL DAMAGE AND TRAPPED FLUIDS

The gel and the cross-linked fluids pumped during fracture treatment cannot be fully recovered during production. In different field studies, it has been found that 60% to 80% of the pumped fluids can be recovered over a long period of time. The amount of fluids recovered decreases, and the recovery time increases, in low-permeability, tight reservoirs. Palmer described a “check valve” effect, where the width of the fracture decreases after treatment and does not allow larger polymers to flow back.2 Also, during injection, the hydraulic gradient is higher and carries the polymers farther away. During the flowback, the hydraulic gradient is much lower and does not generate sufficient force for the fluids to be produced back; therefore, there is need to use polymer breakers to reduce the injected fluid viscosity, as low as possible. For conventional reservoirs, gel damage is compensated by the reservoir permeability and increased apparent wellbore radius due to hydraulic fracturing. In tight formations, and also in naturally fractured reservoirs (therefore in coalbed methane), gel damage is more severe.

BREAKERS

Using the appropriate type and volume of breakers is of prime importance. As much as gel is needed to create the fracture and carry the proppants, it also has to degrade and be produced back to leave a clean and high-conductivity propped fracture behind. Breakers are usually mixed with the fracturing fluid during pumping. Most breakers are typically acids, oxidizers or enzymes. The breakers include ammonium persulfate, ammonium sulfate, copper compounds and glycol. Breaker types include time-release, shear-release, or temperature-dependent.3 Based on a residue-after-break test, it was shown that enzyme breakers leave fewer residues than oxidative breakers used at the same temperature. Polymer degradation by enzymes continues for a much longer time; therefore, it has a cleaner effect on the gel residue after a fracture treatment.

SAUDI ARABIAN APPLICATIONS

Since the inception of hydraulic fracturing, many different types of fracturing fluids have been used in the sandstone gas formations of Saudi Arabia.4 The fluid volume size, gel loading, and additives have been customized to fit the needs of a particular field and reservoir. The fluid quality and type have also advanced during this time, and progressively, new fluid systems are being used.

|

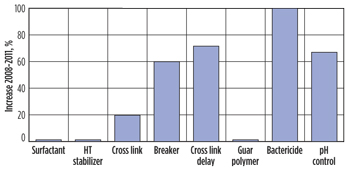

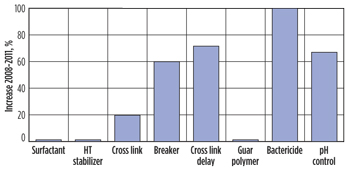

| Fig. 1. Change of additive quantity between 2008 and 2011. |

|

Figure 1 shows a comparison of basic fracture fluid additives used in 2008 and 2011, in a few of the Saudi Arabian wells. Other than some of the fluid chemistry being different, note how the quantity of some of the ingredients has increased over time. The pH control and bactericide are used to maintain the integrity of the fluids and provide compatibility with the formation. The cross-linker concentration is increased, to provide better proppant-carrying capacity at higher concentration, and generate larger fracture widths. The breaking agent, in particular, has increased by more than 60%, indicating the importance of ensuring a clean fracture after the treatment and a quick flowback of the degraded gel.

|

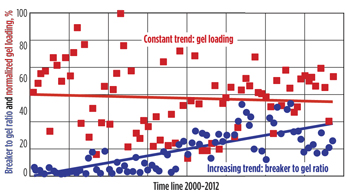

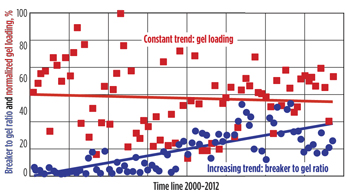

| Fig. 2. Breaker-to-gel ratio in gas wells between 2000 and 2012. |

|

Figure 2 illustrates the breaker-to-gel ratio used in the treatment of about 100 wells analyzed since 2000 (blue dots). It shows the trend of using increased breaker concentration. This change is due to the fact that a higher concentration of breaking agent is conducive to achieving cleaner fractures, and, thereby, higher productivity wells. The field results confirmed the benefits of using a higher breaker amount. Therefore, the trend continues. The gel loading did not change (Fig. 2, red dots), showing that the proppant transport and fracture dimensions were achieved, as per expectation. In fact, there are attempts to decrease the gel loading without compromising fracture quality, so as to incur less damage to the proppant and formation.

|

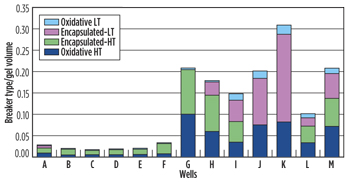

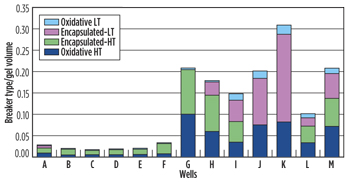

| Fig. 3. Breaker-to-gel ratio for different breaker types. |

|

Figure 3 presents the use of different breaker types and their respective quantities as a function of the total gel volume. The use of both oxidative and encapsulated breakers is necessary, along with their specific activation characteristics, to cover the range of temperature between the cooled-down fracture during the treatment and the reservoir temperature. Therefore, the proper mix of low- and high-temperature (LT and HT) breaking agents is essential, so that the breaking of gel initiates when the fracture closes, and is relatively cool, and continues for a prolonged period, as the fracture eventually attains reservoir temperature.

EXAMPLE WELLS

|

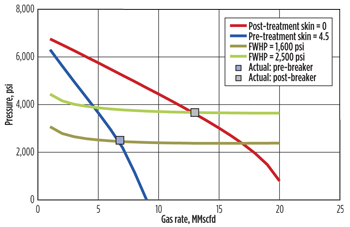

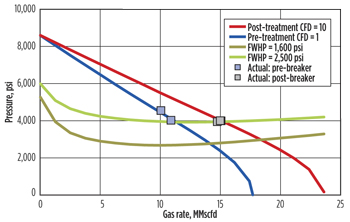

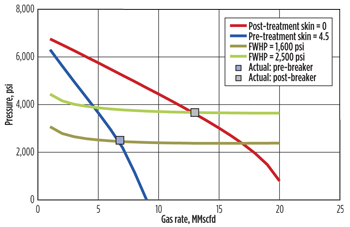

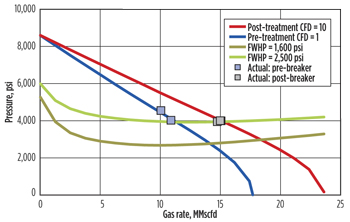

| Fig. 4. Before and after breaker treatment IPR, Well-A. |

|

|

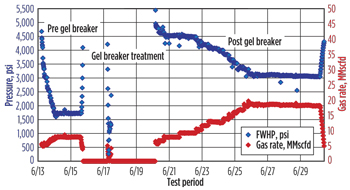

| Fig. 5 . Before and after breaker treatment IPR, Well-B. |

|

|

| Fig. 6. Saudi Aramco Gas Reservoir Management Division (GRMD) team members Alsana (left), Dr. Anazi, Dr. Kanaan (manager), Dr. Rahim and Sharif. |

|

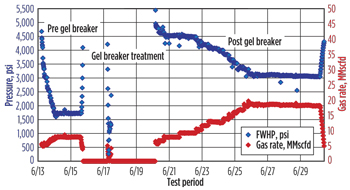

The effects of breaking down the gel are provided from two recent vertical wells, where additional breakers were pumped, after it was realized that the post-treatment production rates were not up to expectations, based on the reservoir development observed from openhole log data and the rates from some of the offset wells. The inflow performance curves from Well-A and Well-B, presented in Figs. 4 and 5, clearly show the improved rates from both wells, where the increase of absolute open flow (AOF) ratio ranged from 25% to over 100%. The improvement varies and depends on the initial treatment schedule, and what was pumped in terms of gel loading and breaker quality. The optimum procedure is to take into consideration all damage and cleanup possibilities, so as to optimize the fluids pumped during the treatment. That way, re-intervention in the well is avoided, saving time and additional expenditure. Consequently, post-frac production analysis must be conducted, and if there is a concern, appropriate measures should be taken. The production rate, before and after breaker treatments, for Well-B is illustrated in Fig. 6, where the well has stabilized at 18 MMscfd at a high flowing wellhead pressure after the treatment. The reservoir lithology, porosity and saturation of the two wells are comparable.

The polymer removal breaker treatment used in the two wells consisted of a high-temperature/high-concentration, water-soluble breaker system. The purpose was to efficiently break any residual gel in the proppant pack, and also leak off into the formation, and clean up the matrix during flowback. Among other components, a bacticide and pH buffer was added, along with corrosion inhibitor, to preserve fluid integrity and make it compatible with the reservoir, as well as the tubulars. Nitrogen was added to enhance flowback. In addition, methanol was pumped to treat any water blockage in the fracture and formation. Removal of water blockage should be considered, because it can significantly hinder gas flow.5

PROPPANT OPTIMIZATION

Good proppant selection is integral to successful hydraulic fracturing. Among the different types of proppants available, the major ones used in Saudi Aramco are the lightweight ceramics and intermediate/high density ceramics, among which some are resin-coated proppants (RCP). RCP is routinely used as a tail-end in the pumping treatment to prevent proppant flowback. This procedure has been working very well. The main criteria of proppant selection depend on the conductivity requirement at downhole conditions. The evaluation is usually done, based on the contrast between the flow capacity of the fracture and the reservoir, known as the dimensionless fracture conductivity.

Selection criteria are based on reservoir pressure and temperature, embedment, multiphase flow and crushing. Also, some very important aspects to take into account while selecting the proppant are the flow convergence effects, particularly in transverse fractures, non-Darcy flow, gel damage, non-optimal proppant concentration and placement, as well as reduced conductivity, due to fines migration and pressure cycling.

Maintaining a high-conductivity fracture is the preferred option to overcome many of the above-mentioned reasons that can reduce gas production rate. A proppant type that can show high conductivity at high stress in the laboratory can, in reality, fall short in maintaining that level of conductivity, due to non-Darcy effects or flow convergence.6 The non-Darcy flow permeability, which is the effective permeability kF, can be computed from the laminar flow equation by relating Darcy permeability kD with flow turbulence expressed by Reynold’s number NRE using the equation: kf = kD/(1 + NRe). Therefore, the higher the Reynold’s number (high flow rate), the lower the effective permeability. In the proppant fracturing jobs performed in Saudi Arabian gas, ensuring an effective conductivity of more than 2,000 md-ft is often required. Even though in the tight reservoirs, this number seems to be high, the higher conductivity helps maintain a long-term rate in reservoirs where condensate drop-out becomes a challenge.

|

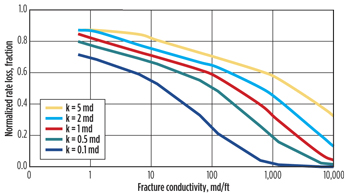

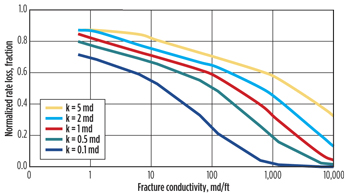

| Fig. 7. Normalized rate loss as function of fracture conductivity for different reservoir permeabilities. |

|

|

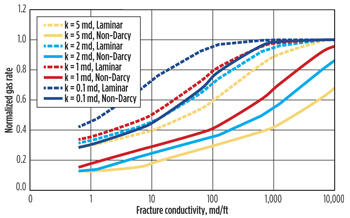

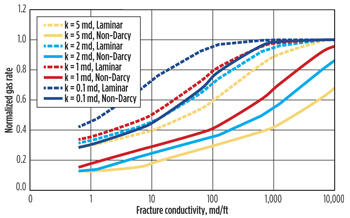

| Fig. 8. Normalized gas rate illustrating both Laminar and non-Darcy effects for different reservoir permeabilities. |

|

Some examples of non-Darcy-related rate loss for some specific reservoir properties in Saudi Arabian gas fields are provided in Figs. 7 and 8. The rate loss is significant in high-permeability wells, due to their high flowrates. For a fracture conductivity of 1,000 md-ft, the rate loss in a 1-md reservoir can be as much as 35%, whereas there will be no loss in a 0.1-md reservoir. Therefore, the selection of proppant type and concentration should be based on reservoir flow capacity. If proppant crushing and embedment conditions are met, high-permeability proppants are always preferred for pumping at high concentration to achieve significant propped fracture width at fracture closure.

CONCLUSIONS

Hydraulic fracturing is a an essential technology to improve gas production from tight gas reservoirs. Many times, the post-fracture expected rate is not achieved, even though the fracture treatment is pumped as designed. Often times this happens because of gel residue in the fracture and sub-optimal cleanup. Efficient polymer breaker treatment contributes to higher well productivity. Low polymer loading and/or adequate amount of breaker is necessary for a complete post-fracture cleanup. Key conclusions and recommendations include:

- Methanol, or similar surface tension reducing agents, should be used routinely to minimize water blockage effects.

- Additional pressure drop, due to non-Darcy flow or flow convergence occurring in transverse fracture geometry, may be significant and will contribute to low well productivity.

- Gas production rate is also adversely affected by the presence of condensate.

- Use of high-strength and high-conductivity proppant, without risking embedment or crushing, is essential for maintaining good connectivity between the well and the formation.

- High-proppant loading can be effective for providing sufficient propped fracture geometry and conductivity.

ACKNOWLEDGMENTS

The authors thank Saudi Aramco for its support and permission to publish this work.

REFERENCES

1. Gupta, S. “Unconventional fracturing fluids: What, where, and why,” Baker Hughes, Tomball, Texas, 2010

2. Palmer, I.D., R. T. Frayar, K. A. Tumino, et al, “Comparison between gel-fracture and water-fracture stimulations in Black Warrior basin,” SPE paper 23415, presented at the Coalbed Methane Symposium, Alabama, U.S.A., May 13-16, 1991.

3. Courtesy of Halliburton.

4. “2009-2012 gas program,” Gas reservoir management division internal documentation, Saudi Aramco.

5. Holditch, S.A., “Factors affecting water blocking and gas flow from hydraulically fractured gas wells,” SPE Journal of Technology, December 1979.

6. Gidley, J., “A method for correcting dimensionless fracture conductivity for non-Darcy flow effects,” SPE Production Engineering, November 1991.

|

The author

ZILLUR RAHIM is a petroleum engineering consultant with Saudi Aramco’s Gas Reservoir Management department (GRMD). Dr. Rahim heads the team responsible for stimulation design, application, and assessment for the non-associated gas reservoirs for GRMD. Prior to joining Saudi Aramco, he worked as a Senior Reservoir Engineer with Holditch & Associates, Inc., and later with Schlumberger Reservoir Technologies in College Station, Texas. Dr. Rahim received his BS degree from the Institut Algerien du Petrole, Boumerdes, Algeria, and M.S. and Ph.D. degrees from Texas A&M University, all in petroleum engineering.

ADNAN AL-KANAAN is the manager of Saudi Aramco’s GRMD, where he oversees three gas reservoir management divisions. Mr. Al-Kanaan graduated from King Fahad University of Petroleum & Minerals with a BS degree in chemical engineering. He was a senior process engineer with Saudi Shell Petrochemical Company and subsequently joined Saudi Aramco in 1997.

HAMOUD A. AL-ANAZI is the general supervisor of the North Ghawar gas reservoir management division Saudi Aramco GRMD. Dr. Al-Anazi oversees all work related to the development and management of gas fields such as Shedgum, Uthmaniyah, and Ain-Dar. He holds a BS degree in chemical engineering from King Fahad University of Petroleum, Saudi Arabia, and MS and PhD degrees in petroleum engineering from the University of Texas at Austin. |

|