|

DR. ROBERT ENICK, University of Pittsburgh; JAMES AMMER, National Energy Technology Laboratory; WILLIAM SCHULLER, URS Corporation

Over the past decades, the Department of Energy and its predecessor organizations supported a large number of laboratory and field research projects—including advanced reservoir characterization, mobility control and CO2-EOR flooding conformance—in an effort to improve the oil recovery process. DOE recently commissioned a CO2 mobility control and conformance control literature review to stimulate interest in developing advance technologies to overcome the geologic and process limitations of CO2-EOR. These limitations include poor sweep efficiency, unfavorable injectivity profiles, gravity override, high ratios of CO2 to oil produced, early breakthrough and viscous fingering.

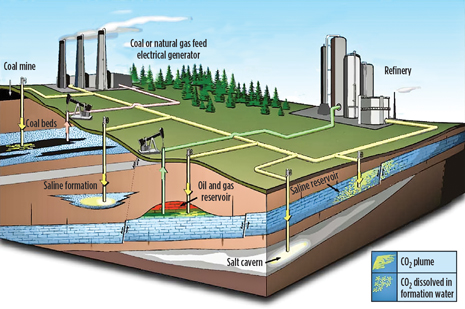

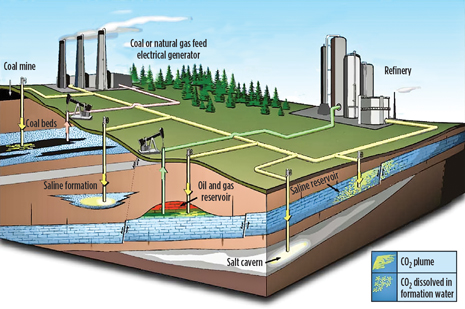

Carbon dioxide enhanced oil recovery has been used commercially to recover oil from geologic formations for over 40 years. Currently, CO2-EOR provides about 280,000 bopd, just over 5% of total U.S. crude oil production, Fig. 1. This percentage is likely to grow in upcoming years, due to high crude oil prices, availability of natural CO2, more in-field drilling, advances in drilling technologies, and the potential availability of large, anthropogenic CO2 sources, Fig. 2.

|

| Fig. 1. U.S. enhanced oil recovery with gases over past decades |

|

|

| Fig. 2. Schematic of CO2 from a thermoelectric power plant and refinery being sequestered in various geologic formations, including CO2-EOR in oil reservoirs |

|

A revised national resource screening assessment for CO2-EOR (July 2011) prepared for DOE by Advanced Resources International concluded:

-

Next generation CO2-EOR can provide 137 billion bbl of additional, technically recoverable domestic oil, with about half (67 billion bbl) economically recoverable at $85/bbl, Table 1.

| Table 1. Oil recovery and CO2 storage from “next generation” CO2-EOR technology |

|

-

This volume of economically recoverable oil is sufficient to support nearly 4 million bpd of domestic oil production (1.35 billion bbl per year for 50 years), reducing oil imports by one-third.

-

Federal and state treasuries, as well as the general U.S. economy, would be large beneficiaries. Total revenues to federal/state treasuries would equal $1.42 trillion, whereas total revenues in the form of wages and material purchases would equal $1.72 trillion.

-

Nearly 20 billion metric tons of CO2 would need to be purchased by CO2-EOR operators to recover the 67 billion bbl of economically recoverable oil. Of this, at least 18 billion metric tons would need to be anthropogenic CO2 captured from industrial sources.

Next-generation technologies include increasing CO2 injection volumes by 50% or more, drilling horizontal wells for injection or production, improving mobility ratio and flood conformance, extending the conditions under which miscibility between the oil and CO2 can be achieved, and applying advanced methods for monitoring flood performance.

Despite the well-established ability of CO2-EOR to recover oil, the process could be improved, if the high mobility of CO2 relative to reservoir oil and water can be effectively and economically reduced. The CO2-EOR industry continues to use water-alternating-with-gas (WAG) as the technology of choice to control CO2 mobility and/or mechanical techniques (e.g., cement, packers, well control, infield drilling and horizontal wells) to help control the CO2 flood conformance, Fig. 3. If the next generation CO2-EOR target of 67 billion bbl is to be realized, new solutions will be needed to recover significantly more oil than the 10–20% of the original oil-in-place associated with current flooding practices.

The premise of the literature review was to highlight prior results, thus providing a baseline understanding of the remaining challenges to and research efforts required for CO2-EOR technology advancement. The review highlighted a number of successes. For example:

-

In the lab, there has been considerable progress in (direct) thickening of CO2 to a level comparable to that of oil and brine for improved mobility control, but no field tests have yet been conducted.

-

Many lab-scale tests and over a dozen field tests involving water-soluble surfactants capable of stabilizing CO2-in-brine foams have been conducted, most aimed at attaining conformance control via the in-situ generation of stronger foams in thief zones.

-

The emergence of robust gel-based conformance techniques (near wellbore) may have led to a decline in the use of foams as a conformance control technique, especially in extremely high permeability flow paths such as vugs and fractures.

-

A large number of lab-scale studies, but only a few field-scale tests, were directed specifically at the design of in-depth (interwell) mobility control foams where in-situ generation of weaker foams was intended to suppress fingering and enhance the rate and cumulative amount of oil recovery.

-

Recently, CO2 foams generated with CO2-soluble nonionic surfactants were successfully tested in the lab and through an ongoing pilot test.

-

Lab-scale testing of foam stabilization with water-dispersible nanoparticles has been initiated in an attempt to circumvent issues, such as adsorption losses and chemical instability of the surfactant, associated with surfactant solutions flowing through a porous medium.

The results of 40 years of research and field testing clearly indicate that mobility and conformance control for CO2-EOR with thickeners, foams and gels can be technically and economically attainable for some fields. However, significantly more research needs to be conducted. The following technologies were recommended as primary candidates for further research:

CO2 viscosifiers (direct thickeners). An affordable CO2 thickener has been recognized as a game-changing technology for over 25 years, but has not yet been developed. Thickener design is a challenge, due to the very low CO2 solubility of high-molecular-weight polymers and smaller compounds that contain the chemical groups responsible for viscosity-enhancing intermolecular associations. An expensive (fluoroacrylate-styrene) copolymer has been shown to effectively thicken CO2, but the continued development of more economically viable CO2 thickeners is required before field tests will be conducted.

Near-wellbore conformance control with CO2 foams and gels. The improved performance of the gel technologies in blocking flow paths, enhanced gel robustness, and the ability to apply gel treatments in fractured or highly permeable open-flow-path formations has made gels the popular choice of many operators for CO2 flooding conformance control. However, a consensus exists that CO2 conformance control foams are less expensive and more readily reversible (via water injection, if desired) than any of the gel treatments. Given the ability of foams to be designed for conformance and/or mobility control, it may be prudent to combine the two technologies, where gels are employed, for conformance control, and CO2-in-brine foam (rather than WAG) is used for mobility control.

In-depth mobility control CO2 foams. Research results have demonstrated that surfactant-induced CO2 foams are an effective method for mobility control in CO2 foam flooding, but have potential weaknesses. Because the foam is by nature ultimately unstable, its long-term stability during a field application in oil-bearing zones is difficult to maintain. But CO2 mobility control via the alternating injection of aqueous surfactant solutions and brine has not been fully explored in pilot tests.

Foam generated by the alternating injection of CO2-surfactant solutions and brine ensures that the surfactant will be present (and the foam forms) where the CO2 flows. An ongoing field test indicates that the foam may provide some degree of conformance and mobility control. The use of liquid, non-ionic, CO2-soluble surfactants may be especially advantageous for operators who only employ continuous CO2 injection, and may reduce the size of the brine slugs for operators who choose a CO2 and brine injection scheme. Because the CO2-soluble surfactants are also water-soluble, the surfactant could conceivably be added to both the CO2 and brine slugs.

New nanoscience technologies may also provide an alternative to generation of stable CO2 foam. Nanoparticles readily disperse in water, and this dispersion readily flows through unconsolidated porous media. Using nanoparticles instead of surfactant to stabilize CO2 foam may overcome the long-term instability and surfactant adsorption loss issues that affect surfactant-based CO2-EOR processes.

DOE’s Office of Fossil Energy, through the National Energy Technology Laboratory (NETL), awarded a number of new research projects in 2010, seeking to further next-generation CO2 EOR to the point of pilot (small) scale testing. Three of these activities are related to mobility control in CO2 flooding; two are focused on nanoparticle technologies, and one on CO2-soluble surfactants. A fourth research activity is field-testing gels for conformance control.

Parts 2, 3 and 4 of this series will cover CO2 foams for mobility and conformance control, field tests of CO2 foams and conformance control gels, and CO2 additives--—direct thickeners, foam-stabilizing surfactant agents and nanoparticles.

REFERENCES

Koottungal, L, “2010 worldwide EOR survey,” Oil and Gas Journal, April 19, 2010, Vol. 108, No. 14, pp. 45–60.

Kuuskraa, V. A., T. Van Leeuwen, and M. Wallace, “Improving domestic energy security and lowering CO2 emissions with ‘next generation’ CO2-enhanced oil recovery (CO2-EOR),” DOE/NETL 2011/1504, June 20, 2011, pp. 1–113. Available at: www.netl.doe.gov/energy-analyses/refshelf/PubDetails.aspx?Action=View&Source=Main&PubId=391

Lindley, J., “Series of enhanced oil recovery, drilling and waterflood illustrations,” U.S. Bureau of Mines and succeeding organizations – Energy Research Development Administration and U.S. Department of Energy, Bartlesville, OK, ca. 1960.

|

AUTHORS

|

|

DR. ROBERT ENICK is the Bayer Research Professor of Chemical and Petroleum Engineering at the University of Pittsburgh, and has worked in various capacities with NETL scientists since 1987. He has developed numerous compounds designed to dissolve in CO2, including direct CO2 thickeners, for over 20 years. Enick led the team that designed the fluoroacrylate-styrene copolymer (polyFAST) direct thickener—the only compound identified to date capable of increasing CO2 viscosity by a factor of ~10 at a concentration of ~1wt% at minimum miscible pressure (MMP) conditions without the need for a co-solvent. In recent years he has identified numerous commercially available, non-ionic, CO2-soluble surfactants with the potential to form CO2-in-brine mobility control foams in-situ as CO2-surfactant solution is injected into the formation.

|

|

| JAMES AMMER is the Director of the Natural Gas & Oil Project Management Division at the National Energy Technology Laboratory, which manages external R&D projects funded through the Department of Energy’s Office of Fossil Energy Natural Gas and Oil Program. Previously he served as a project manager for 10 years, managing projects in drilling, stimulation, production optimization, natural fracture detection and prediction, and gas storage. Ammer also conducted reservoir engineering and simulation studies for over 10 years, including studies on CO2 flooding, gas migration analysis, horizontal drilling evaluation and gas storage efficiency. He received his BSc degree in Petroleum and Natural Gas Engineering from Pennsylvania State University in 1983. Ammer has been employed at NETL for over 27 years. |

|

| WILLIAM SCHULLER is a Senior Scientist with URS Corporation (Energy and Construction Services Division, Global Management and Operations Services Business Unit) providing technical support to DOE’s National Energy Technology Laboratory’s (NETL) Office of Research and Development. Additionally, he is the Oil and Gas Program Lead for Team KeyLogic (KeyLogic, Inc. and URS joint venture) providing project execution and integration services support to the Natural Gas and Oil Project Management Division at NETL. Schuller has a BS in Geology from West Virginia University and has over 35 years of oil and gas experience in reservoir characterization and production enhancement. |

|

|