ROBERT ENICK, University of Pittsburgh; JAMES AMMER and ALBERT YOST, National Energy Technology Laboratory; WILLIAM SCHULLER, URS Corporation

The previous segment in this series indicated that a multitude of promising lab-scale studies of CO2 foams for conformance and/or mobility control have been published. Thirteen field tests of CO2 foams occurred between the mid-1980s and mid-1990s. This decade-long experiment provided valuable insights into the technical strengths and weaknesses of CO2 foams for mobility and conformance control in sandstone and carbonate formations to recover additional oil. The majority of field tests involved the use of alternating slugs of aqueous surfactant solution and CO2 (surfactant-alternating-gas, or SAG). Although much of the lab-scale work on CO2 foams was related to mobility control, 11 of the 13 field trials were designed primarily to achieve near-wellbore conformance control due to many factors: shorter duration of the conformance control treatment, higher likelihood that the CO2 would mix thoroughly with the previously injected surfactant slug in high-permeability zones near the wellbore, possible deleterious effects of high oil saturation on foam stability during mobility control tests, and ability to generate strong near-wellbore foams by increasing the surfactant concentration.

Five of the conformance control CO2 foam tests were considered to be technical successes, one was a partial success, one was inconclusive, and four were unsuccessful. Both foam tests intended solely for mobility control yielded disappointing results.

Two successful conformance control field test results include:

• Chevron’s North Ward-Estes conformance control test [Chou et al.

1992], where foam formation reduced injectivity by 40-85% and

diverted CO2 from a high permeability zone. Carbon dioxide

production at the problematic producer was reduced while CO2

production increased at other offset producers. Incremental oil was

recovered, CO2 recycling was greatly reduced, and the CO2 foam

was more effective at reducing flow into the higher permeability zone

than the WAG process.

• A very short cycle SAG injection into Well 31 in Mobil’s Slaughter

Field, East Mallet Unit [Hoefner and Evans, 1995] reduced gas

injectivity. Injection profile logs indicated that fluids were completely

diverted from the top injector perforations, which included the thief

zone. Gas production was cut by as much as 50% in Well 98, and

the diminished gas flow continued for eight weeks after the SAG

process ended. Oil production in the entire pattern increased by

about 26%.

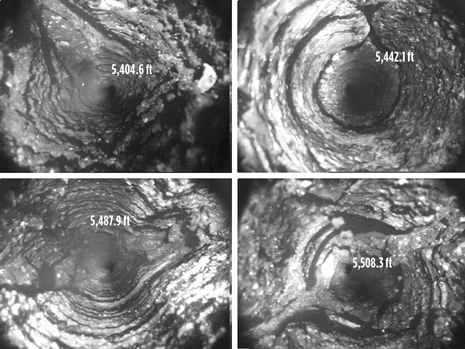

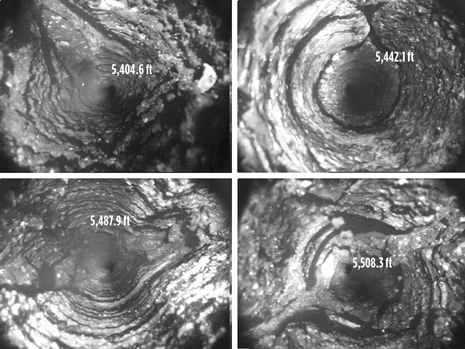

The lessons learned from the CO2 foam tests include a) CO2 foams used after traditional CO2 flooding could lead to the recovery of incremental oil; b) a sacrificial surfactant pad should be injected prior to SAG to minimize surfactant adsorption losses during SAG; c) formation damage was not problematic; d) water injection into the reservoir immediately after foam generation could lead to foam dissipation; e) SAG was easier to manage in the field and had fewer injectivity problems than co-injection; f) formations well suited for CO2 foams contained a single pay zone or thief zones that were not vertically isolated from oil-rich target zones; g) foams were not as effective in formations with natural or induced fracture networks; and h) foams were ineffective in highly heterogeneous formations characterized by void space conduits (VSCs) such as karsts, cavities, vugs, natural and induced fractures, and openings enhanced by dissolution during water- and CO2-flooding such as those shown in Fig. 1. With respect to the economics of these field tests, the price of oil was quite low ($15–$20 per barrel) when they were conducted. As a result, only three of the five technical successes were also deemed economic successes.

|

| Fig. 1. Downhole camera inspections of near wellbore reveal large void space features that are more conducive to treatment with gels than foams; Anton Irish field (from Smith et al. 2006) |

|

Carbon dioxide foams also faced stiff competition. Operators desiring mobility control considered in-depth SAG or WAG, while those desiring conformance control could choose strong near-wellbore CO2 foams or gels. Five techniques have been employed for introducing a gel into a formation prior to conformance control during a CO2 flood. A monomer solution can be injected that polymerizes in situ, yielding anything from a flowing or lipping gel to a full rigid ringing gel. The second gel type involves the injection of a monomer+crosslinker (typically trivalent ions that became available for crosslinking in situ by the passage of time and/or an increase in temperature) solution that both polymerizes and crosslinks in situ. The third type of gel, which was reported frequently, starts on the surface as a polymer+crosslinker solution that crosslinks in situ, yielding anything from a flowing and lipping gel to a rigid ringing gel. The fourth gel type was a CO2-foam gel composed of a viscous polymer solution (an aqueous polymer+crosslinker+surfactant solution) that produced gelled lamellae in situ. The fifth type of gel was associated with an aqueous dispersion of pre-formed particle gels (PPGs), which starts out on the surface as a dispersion of dehydrated crystalline particles of rigid ringing gel that has a high affinity for absorbing water into the complex gel matrix. Once the particles are re-hydrated in situ, they take the form of disaggregated chunks of rigid ringing gel that are not chemically bound to one another.

The monomer-based solutions have very low viscosity values (~1 cP), enabling them to flow readily into low and high permeability media prior to polymerizing and forming a gel. The polymer-crosslinker solution is much more viscous (20–100s cP, pre-crosslinking) and the molecules can be of extremely high MW (up to 18 million Dalton); therefore, polymer-crosslinker solutions effectively block high permeability thief zones and fractures rather than lower permeability oil-bearing zones. Because PPGs are typically composed of dehydrated particles that are a few millimeters in size, they can only penetrate and plug VSCs.

A dozen field tests of CO2 conformance control gels were reported between 1978 and 2010, with most occurring since the mid-1990s. The earliest gel was not resistant to the low pH of CO2 during flooding (a small amount of the CO2 that dissolves in brine forms carbonic acid and lowers the pH to ~3). Ten of the subsequent 11 conformance control gel projects were very successful, and it was fortunate that field testing was conducted when the price of oil was in the $20–$100 per barrel range.

Two noteworthy field tests of gels [Sydansk and Southwell, 2000] include:

• Amoco’s Wertz field, where 10 wells were treated with gels that

extended the economic life of the field by two years, enabling the

production of 35,000 to 140,000 bbl of oil per pattern.

• Eighty percent of the 49 wells treated with gels at Rangely-Weber

Sand Unit between 1994 and 1997 were considered successes. The

$2,060,500 investment yielded 685,000 incremental barrels of oil,

which resulted in a 365% rate of return and an 8-month payout period.

Lessons learned from carbon dioxide conformance control gel tests include a) the gel must be robust enough to handle the reservoir conditions of a CO2 flood—particularly low pH; b) gels are not readily reversible, thus gel solution preparation and injection operations must be conducted efficiently; c) gels can be placed in injection wells or production wells; d) CO2 may eventually find a flow path around a gel; e) carefully designed gels can yield very favorable results for many years; f) advances in monomer chemistry have yielded safer monomers; g) both monomer systems and lower MW polymer systems are capable of entering low permeability (< 100 mD perm) media, but h) only very high MW gels (> 6 million Dalton) and PPGs are capable of mitigating the extraordinarily high conductivity of void space conduits without damaging the lower permeability rock.

Rather than considering gels and CO2 foams as an “either/or” option, they should be considered based on their different attributes in various types of formations. Carbon dioxide foams are reversible and relatively inexpensive tools that are best suited for conformance control in non-fractured formations—especially those with a multiple thin intra-zonal thief zones or thief zones not vertically differentiated by shale layers from target zones. Carbon dioxide foams can also be designed for in-depth, long-term mobility control. Gels are more expensive and robust technologies designed for conformance control in more challenging reservoirs, especially those characterized by natural and induced fractures or VSCs. Therefore, it is critical to obtain as much information as possible about the formation prior to deciding on conformance or mobility control using CO2 foams and/or conformance control with gels.

The final, part 4 of this series will cover CO2 additives: direct thickeners, foam-stabilizing surfactants, and nanoparticles.

LITERATURE CITED

1. Chou, S.I.; Vasicek, S.L.; Pisio, D.L.; Jasek, D.E.; Goodgame, J.A.: “CO2 Foam Field Trial at North Ward-Estes,” SPE 24643, presented at the 67th SPE Annual Technical Conference and Exhibition, held in Washington, D.C., October 4–7, 1992.

2. Hoefner, M.L.; Evans, E.M.: “CO2 Foam: Results from Four Developmental Field Trials,” SPE Reservoir Engineering, November 1995, pp. 273–281.

3. Smith, D.D.; Giraud, M.J..; Kemp. C.C.; McBee, M.; Taitano, J.A.; Winfield, M.S.; Portwood, J.T.; and Everett, D.M.: “The Successful Evolution of Anton Irish Conformance Efforts,” SPE 103044, presented at the 2006 SPE Annual Technical Conference and Exhibition held in San Antonio, TX, September 24-27, 2006.

4. Sydansk, R.D.; Southwell, G.P.: “More than 12 Years of Experience with a Successful Conformance-Control Polymer Gel Technology,” SPE Production and Facilities, Vol. 15, No.4, November 2000, pp. 270–278.

|

The authors

|

|

ROBERT ENICK is the Bayer Research Professor of Chemical and Petroleum Engineering at the University of Pittsburgh, and has worked in various capacities with NETL scientists since 1987. He has developed numerous compounds designed to dissolve in CO2, including direct CO2 thickeners, for over 20 years. Dr. Enick led the team that designed the fluoroacrylate-styrene copolymer (polyFAST) direct thickener—the only compound identified to date capable of increasing CO2 viscosity by a factor of ~10 at a concentration of ~1wt% at minimum miscible pressure (MMP) conditions without the need for a co-solvent. In recent years he has identified numerous commercially available, non-ionic, CO2-soluble surfactants with the potential to form CO2-in-brine mobility control foams in-situ as CO2-surfactant solution is injected. |

|

|

JAMES AMMER is the director of the Natural Gas & Oil Project Management Division at the National Energy Technology Laboratory (NETL), which manages external R&D projects funded through the Department of Energy’s Office of Fossil Energy Natural Gas and Oil Program. Previously he served as a project manager for 10 years, managing projects in drilling, stimulation, production optimization, natural fracture detection and prediction, and gas storage. Ammer also conducted reservoir engineering and simulation studies for over 10 years, including studies on CO2 flooding, gas migration analysis, horizontal drilling evaluation and gas storage efficiency. He received his BSc degree in Petroleum and Natural Gas Engineering from Pennsylvania State University in 1983. Ammer has been employed at NETL for over 27 years. |

|

|

ALBERT YOST is technology manager for the Traditional Oil and Gas Program at the Department of Energy’s National Energy Technology Laboratory (NETL) in Morgantown, W.Va. He serves as oil and gas technical advisor to the director, Strategic Center for Oil and Gas at NETL, and also manages a multi-million-dollar portfolio of research projects focused on accelerating the recovery of domestic unconventional oil and natural gas resources, EOR, and mitigating environmental impact. Mr. Yost has more than 35 years of experience in management of federal research related to horizontal drilling and stimulation; EOR using CO2; natural gas storage, transmission, and distribution; and water-related environmental research. He has published more than 30 papers related to unconventional gas and EOR. He received a BS in petroleum engineering in 1975 and an MS in petroleum engineering in 1982 from West Virginia University. |

|

|

WILLIAM SCHULLER is a senior scientist with URS Corporation (Energy and Construction Services Division, Global Management and Operations Services Business Unit) providing technical support to DOE’s National Energy Technology Laboratory’s (NETL) Office of Research and Development. Additionally, he is the Oil and Gas Program Lead for Team KeyLogic (KeyLogic, Inc. and URS joint venture) providing project execution and integration services support to the Natural Gas and Oil Project Management Division at NETL. Schuller has a BS in Geology from West Virginia University and has over 35 years of oil and gas experience in reservoir characterization and production enhancement. |

|