NELL LUKOSAVICH, Senior Editor

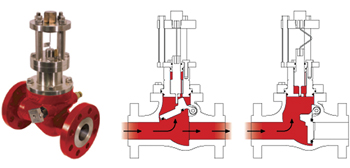

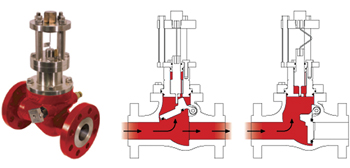

Inline modified check valve

Flowing pressure acting on the unbalanced stem area puts an axial force on the pin. At set point, the pin buckles, and the valve closes for a bubble-tight seal. Rupture Pin Technology’s Model "JA" isolates pressure to prevent downstream damage. It is environmentally friendly by eliminating air and ground pollution common with conventional relief valves.

Rupture Pin Technology has also introduced its Frac Valve, which is designed for use instead of shear pin or spring reset valves, where greater accuracy and reliability are needed. This state-of-the-art, frac fluid relief valve is engineered for relief settings up to 15,000 psi. It reaches open position in milliseconds.

www.rupturepin.com

Digital valve controller with PROFIBUS PA

Emerson has extended the Fisher FIELDVUE digital valve controller family with the addition of the FIELDVUE DVC6200p PROFIBUS PA digital positioner. This digital valve controller is built on Fisher’s linkage-less, non-contact sensor technology. For throttling control applications, the FIELDVUE DVC6200p offers an analog output function block, while a digital output function block is available for on/off applications. Utilizing PROFIBUS PA, the DVC6200p provides alerts, trends and diagnostics to allow for process visibility and control not previously available in a PROFIBUS PA digital valve controller. A quick setup and calibration, including performance tuning, can be performed locally. For more extensive parameterization, PROFIBUS configuration tools can be used. The DVC6200p supports enhanced device description files that allow for quick and easy configuration. The digital valve controller is certified to Profile 3.02 for PROFIBUS PA devices by the PROFIBUS Nutzerorganization a.V (PNO). CSA, IEC Ex, and FM approvals are available now for the DVC6200p.

www.FIELDVUE.com

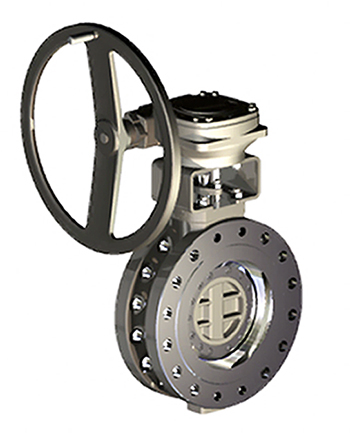

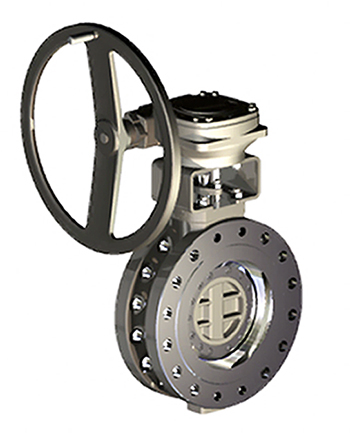

Triple offset shutoff valve for critical applications

Cameron has expanded its valve portfolio to include the NEWCO TOV. This triple offset valve is engineered to include a self-centering disc for bubble-tight shutoff, a sealed bearing design, a standard Stellite body seat, and positive stem retention. The valve is designed to reduce drag on the seat significantly, minimizing wear and increasing valve life. The valve is engineered for reliable performance in upstream production, storage and transmission, petrochemical and chemical, and steam and steam distribution applications.

www.newcotov.com

Hydraulic pump actuates valves without emissions

Oklahoma-based Kimray Inc. used nearly 65 years of industry experience to develop the patent-pending Kimray Electro-Hydraulic Actuator. Using a high-efficiency hydraulic pump, users can actuate valves completely without emissions. By pairing the Electro-Hydraulic Actuator with a small solar panel, the solution becomes self-contained and energy-independent. The EHA (Electro-Hydraulic Actuator) can be used with any Kimray high-pressure control valve actuator or other linear actuated valve, although actuation times may vary. For all versions of the actuator, hydraulic oil is shuttled from the area on top of the diaphragm to the area underneath the diaphragm through a manifold. For a Pressure Opening (PO) valve, the volume on the top of the diaphragm acts as a storage space for hydraulic oil at atmospheric pressure. The volume underneath the diaphragm is pressurized to actuate the valve open. An oil reservoir is attached to the top of the valve actuator to allow for hydraulic oil input and visual measurement of the hydraulic oil level. The EHA can be used with either a PO valve or a Pressure to Close (PC) valve.

When a signal is received through the control circuit to open a PO valve, the pump is activated, and begins to move and pressurize the hydraulic oil out of the top of the diaphragm space, through the pump and into the volume underneath the diaphragm. The valve actuator begins to open the valve. For the Discrete (ON/OFF) version (Valve Actuator), the pump continues with pressure being monitored by the pressure transducer until the maximum set point is reached. At that point, the pump is deactivated, and the valve remains open.

When a signal is received through the control circuit to close a PO valve, the solenoid valve is open and begins to allow for the movement and de-pressurization of the hydraulic oil out from underneath the diaphragm through the solenoid valve and into the volume above the diaphragm. The valve will stay in position until a signal is received through the control circuit. Depending on solenoid valve selection, the valve will return to normal state or remain in place. When ordered with the fail-in-place option, the valve will remain in place in the event of power failure. When ordered with the fail-safe option, the valve will close or open for PO and PC valves, respectively, in the event of power loss.

www.kimray.com

Surface safety valve

Schlumberger’s surface safety valve (SSV) is a hydraulically actuated fail-safe gate valve for testing oil and gas wells with high flowrates (>1,280 m3/d [>8,000 bbl/d] or >850,000 m3/d [30,000,000 ft3/d]), high pressures (>34,475 Pa [>5,000 psi]), or the presence of H2S. The SSV is used to quickly shut in the well, upstream of the choke manifold in the event of overpressure, failure, a leak in downstream equipment, or any other well emergency requiring an immediate shut-in.

The SSV is remotely operated by an emergency shutdown device (ESD), which can be triggered automatically by high- or low-pressure pilot actuators. If an emergency occurs, this feature reduces the possibility of personnel injuries.

A number of SSV models are available for different well conditions (pressures, temperatures and flowrates) and with various connections, such as Grayloc or API-6A flanges. All SSV models have interchangeable crossover connections and are protected by a compact, removable lifting frame.

The SSV uses a proven metal-to-metal, double-sealing design for harsh environment operations and complies with all applicable environmental requirements. All SSVs are manufactured under Type Approval or Design Verification Review and provided with a Certificate of Conformity and full quality file.

www.slb.com

Pressure relief valve with wireless position monitor

The Farris SmartPRV, from Curtiss-Wright Flow Control Company’s Farris Engineering business unit, is a 2600 Series Pressure Relief Valve (PRV) equipped with a Fisher 4320 wireless position monitor. With the new wireless technology, PRVs can be monitored in real time, providing immediate feedback during an overpressure event. Areas of the plant that had previously been difficult or impossible to track using traditional wired products can now be monitored effectively. The valve can help identify production and profitability losses, reduce emission fines and associated administrative costs, and improve plant safety and environmental performance.

www.farris.cwfc.com

Multi-turn electric valve actuator for flow control

Rotork has introduced the third generation of its IQ range of intelligent, non-intrusive, heavy-duty electric valve actuators. The Rotork IQ3 multi-turn actuators are designed to provide new levels of functionality and asset management. Advanced features include operational, data logging, and ease-of-access capabilities, such as a large, dual-screen, wide-angle local display that provides real-time asset management data and a new secure Bluetooth hand-setting tool for convenient set-up, configuration, commissioning, and real-time data access. Several mechanical enhancements include separately-removable thrust bases across the entire range, which allow the actuators to be safely removed from the valve without altering valve position. Rotork IQ3 multi-turn electric valve actuators are designed for rugged, challenging environments, and for a range of flow control applications in various industries. The valve actuators can be used for virtually any type of valve, either by direct attachment or in combination with secondary gearboxes.

www.iqactuator.com

|