TIINA M. KOMULAINEN, RONNY SANNERUD, Oslo and Akershus University College; BJARNE NORDSTEIEN and HAVÅRD NORDHUS, Statoil

|

| An advanced drilling and well simulator, which combines top-side and downhole simulation, is used for operator training at Statoil.9 |

|

According to a recent study by ARC Advisory group1, the real-time process optimization and training market will reach more than $1.5 billion in 2015. To ensure safe, stable growth in the industry, the experience and knowledge of retiring professionals have to be transferred to new operators in a fast, effective manner.

High-fidelity operator training simulators (OTS), including the main process model and stimulated or emulated distributed control system, have been used for more than 20 years in the oil and gas indusry.2 The high-fidelity OTS allows realistic, hands-on training of normal operations, start-ups and shutdowns, upsets and emergency situations without compromising the health and safety of the operators, the well integrity and the surrounding environment.1,3 OTS’s are typically also used for training before major technology upgrades, training of procedures, and for regular refresher courses on rare emergency events.

There are numerous benefits related to the simulator utilization, including safety improvements, shorter start-ups through process and DCS system testing, enhanced operator performance, trip and incidence avoidance, and knowledge transfer.4,8 Fiske has referred to an OTS study in the hydrocarbon processing industries, estimating a payback of about three months, due to reduced training costs, fewer environmental incidents, less damage to the equipment and increased plant availability. The OTS is often used for other purposes, such as to test the DCS system and process modifications by engineers, thus, improving the outcome of the OTS investments.

Cheltout, et al, report that the OTS maintenance is often a challenge for resource and expense allocation over the whole lifetime of the simulator.3 A continuous effort must be carried out to plan and budget updates to the OTS. Cheltout, et al, suggest that either the process engineers take major responsibility for the OTS or outsource the maintenance.

Considerable efforts have been made to improve the technical quality, additional functionalities and usability of the high-fidelity simulators.1,8,9 Online simulators using real-time process data have been suggested by various simulator suppliers.2,10 Use of a virtual reality simulator is well known from other fields, such as aviation and medicine; Virtual reality training simulators have been developed for both control room and outside operations.1,6,12 Abel encourages further development of high-fidelity, 3D virtual reality simulators to attract young people, embracing the latest technology for the oil and gas industry, and providing a more realistic training environment.

The simulator vendors have made less effort on how the OTS should be used for operator training, i.e. the pedagogical side of the simulator training and the design of the training sessions. Recently, however, the focus on simulator training technology has started to shift from the development of simulator software, including mathematical process modeling and graphical user interface, and the simulator room design (“look and feel”), to the training course setup, including training objectives, lesson plans, training exercises and evaluation criteria, as described by Glaser.5 An important part of an operator training course is teaching the team and supervision skills, as pointed out by Glaser and Sneesby.11 Sneesby estimates that the “soft benefits” of the OTS training might be more valuable in the long term than the immediate benefits of a faster start-up.

SURVEY BACKGROUND

An electronic questionnaire was sent to about 250 simulator users in the Norwegian oil and gas industry. The responses were collected during the period, October–December 2011. The questionnaire included 40 questions with predefined answer alternatives and a commentary field. The aim of the survey was to quantify the benefits of simulator training in the Norwegian oil and gas industry.

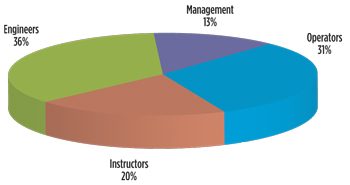

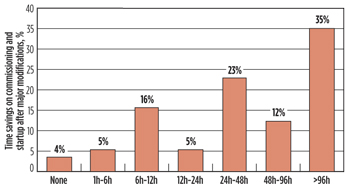

A total of 99 answers was received from 11 different companies, including Statoil, Shell, AddEnergy, ConocoPhillips, BP, Petrolink, Gaz de France, ExxonMobil, Marathon, Talisman, and Sørco. All the groups related to simulator training were represented in the study; including operators, instructors, process engineers, automation engineers, system engineers and management, Fig. 1. Most of the participants were experienced, and 75% had more than ten years of experience in the oil and gas industry.

|

| Fig. 1. Simulator user groups participating in the study |

|

SIMULATOR UTILIZATION

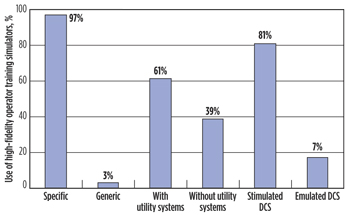

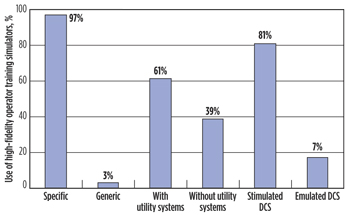

High-fidelity simulators are widely used in the Norwegian oil and gas industry. While most of the participants (97%) used a plant-specific simulator, only 3% of the participants used a generic process simulator. The plant-specific simulators typically included both simulated control systems (81%) and utility systems (61%), Fig. 2. Around 70% of the plants had one simulator for operator training, whereas 30% had two or more simulators available for operators. Most of the companies (89%) also facilitated OTS use for engineering purposes. At 45% of the plants, operators and engineers were sharing the OTS, whereas 44% had a separate OTS for engineers. The operator training simulators were thus used for various purposes, such as verification of process, equipment and DCS system changes (69%), verification of new DCS screens (57%), dynamic simulation studies, production optimization and debottlenecking (57%), pre-operational and operational support (53%), control strategy development (52%) and verification of new procedures (51%).

|

| Fig. 2. Use of high-fidelity operator training simulators in the Norwegian oil and gas industry |

|

KEYS TO SUCCESSFUL TRAINING

About 60% of the survey participants had been closely involved with simulator training, either in the planning phase, or as instructors or course participants. During the initial operator training period, the new operators used simulators, on average, nine days. A refresher course for the experienced operators is arranged, once or twice a year on average, but some have the opportunity to train before each offshore trip. The simulator course availability is limited, due to training center capacity and availability of the instructors.

The learning program was well presented—84% of the respondents were aware of the learning goals, and only 5% were not familiar with the simulator course objectives. The most popular teaching methods were training with different simulation scenarios (60%-72%), Powerpoint presentations (37%), simulation scenario demonstrations by the instructor (33%) and traditional classroom/theory exercises (20%). A usual selection of simulator course elements included start-up and shut-down operations (82%), system familiarization and work flow studies (70%), safety training (67%), emergency response management (65%), process upsets and hardware/software failures (60%) and operating procedures (60%). The evaluation was typically done continuously (65%) during the simulation exercises, with a focus on right response (58%), good team work (57%), wrong response (50%) and achieved learning goals (48%). Only one-third of the participants reported on written exams after the simulator course.

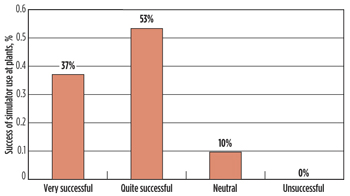

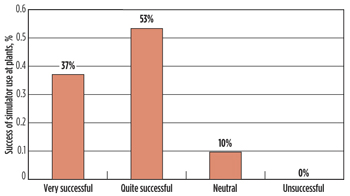

Over 90% of the participants evaluated the simulator use at their plant as very successful or successful, and none as failed/ unsuccessful, Fig. 3. The key factors to successful simulator training were skilled instructors, an up-to-date simulator model, and a proper simulator organization.

|

| Fig. 3. Success of the simulator use |

|

SIMULATOR MAINTENANCE

All the key factors to successful operator training are related to the simulator organization and maintenance. About two-thirds of the plants have more than one group that is responsible for the simulator maintenance. Most commonly, the instructors (47%), system engineers (45%) or the simulator vendor (27%) do the simulator updates after the process and DCS system changes. Only one-fourth of the participants were satisfied with how the maintenance responsibility is currently divided; many hoped that the management and the process engineers would engage more in the maintenance work.

Simulator models are updated after every major change (53%), depending on budget or annual evaluation (30%) or after every minor change (10%). Only 1% of the respondents indicated that the simulator has not been maintained in the past five years. The simulator model state, i.e. the initial condition, is updated once a week (7%), once a month (7%), four times a year (10%), twice a year (7%), once a year (17%), seldom (45%) or never (7%). Infrequent updates of the simulator model and the simulator state can cause large discrepancies between the real process and the simulator model, and cause problems in training. The operators can lose their confidence on the model, and the training of the current operational problems or the production changes can be impossible.

Problems with maintenance are related to prioritization in the simulator organization (67%), lack of qualified personal (37%), costs (28%), a large amount of work to be done during simulator maintenance (26%) and lack of procedures for updating (22%).

SIMULATOR TRAINING BENEFITS

The benefits of simulator training can be categorized into HSE improvements and economic benefits. According to the operators, the three most important benefits of OTS usage are:

-

Improves my understanding of the process and makes me more confident on operating the process safely (84%),

-

Improves my ability to handle process upsets (81%),

-

Makes me more confident and comfortable on my daily work (71%).

-

According to the instructors, engineers and managers, the three most important benefits of the OTS use are:

-

Faster production start-up (79%),

-

Reduced operational risk and enhanced facility integrity (72%),

-

High production performance (62%).

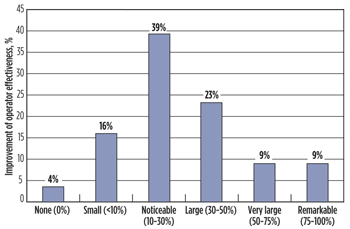

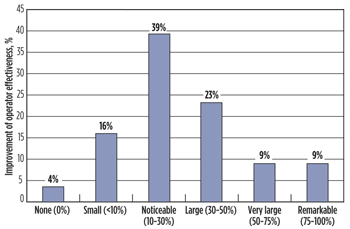

Over 80% of the participants estimate noticeable to remarkable improvement of operator effectiveness, due to simulator training in their facilities. The average estimate of operator effectiveness improvement was 31%, as shown in Fig. 4.

|

| Fig. 4. Improvement of operator effectiveness |

|

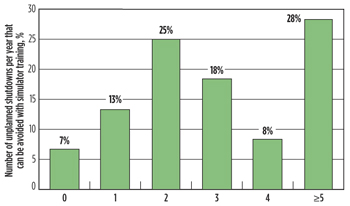

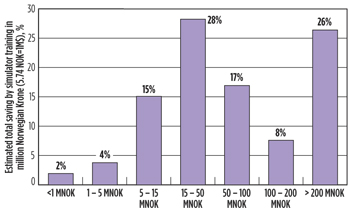

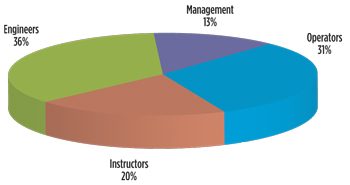

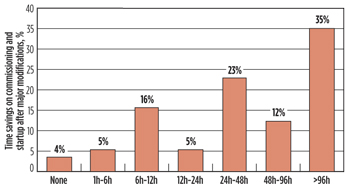

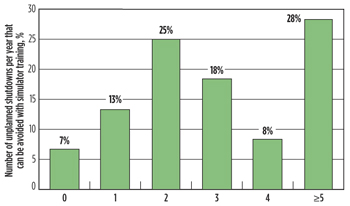

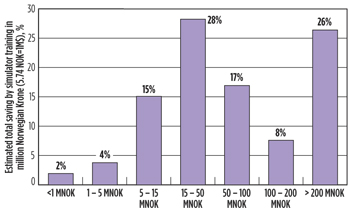

Due to simulator training, an average of 18 days can be saved on commissioning and start-up, and an average of 53 hours (2.2 days) on commissioning and start-up after major modifications, as indicated in Fig. 5. Operator training with the simulator also helps to prevent unnecessary downtime by reduction of unplanned shutdowns, on average three per year per plant, as shown in Fig. 6. Almost 80% of the participants estimated the savings, due to simulator training, to be over $2.6 million, and 26% of the participants considered the savings to be over $38.4 million. On average, the total savings were estimated to be $15.3 million, as presented in Fig. 7. Over half of the participants assess the payback time to be under six months, but the average payback estimate is 14 months. It is worth noting, that although the profitability estimates are not following normal distribution, the highest estimates are given by participants with different backgrounds. This might be due to more successful utilization of simulators on some platforms than others, and also across companies.

|

| Fig. 5. Time savings on commissioning and start-up after major modifications |

|

|

| Fig. 6. The number of unplanned shutdowns per year that can be avoided with simulator training |

|

|

| Fig. 7. Estimated total saving by simulator training (million Norwegian Krone, 5.74 NOK =$ 1) |

|

CONCLUSIONS

Operator training with simulators has been successful among the Norwegian oil and gas companies included in the survey. All the participating groups—operators, instructors, engineers and management—attributed remarkable benefits related to operator training. For the operators, the benefits come from repeated team training on rare events, process upsets and new procedures, which, in turn, increases confidence, enhances effectiveness and decreases work-related stress. For the plant and company, the benefits come from accelerated time to production start-up, reduced operational risk, enhanced facility integrity and increased production performance.

The average estimate of operator effectiveness improvement was 31%. Commissioning and start-up required less time, on average 18 days less for a new facility, and 2.2 days less for an existing plant after major modifications. Simulator training reduced unplanned shutdowns, on average three per year, per plant. On average, the total savings were estimated to be $15.3 million per plant, and payback time was under 14 months. The operator training simulators are used for various purposes other than training, thus increasing the value of the simulator investment.

To make the simulator training even more successful, special attention has to be paid to simulator maintenance, education of new instructors and further development of training materials. A combination of skilled instructors, up-to-date high-fidelity simulators and pedagogical course material are essential for ensuring the best possible training for the new and experienced operators in the oil and gas industry.

REFERENCES

1. Abel, J. , "Aging HPI workforce drives need for operator training systems.," Hydrocarbon Processing, November 2011, pp. 11-16.

2. McArdle, S.; D. Cameron and K. Meyer, "The life cycle simulator: From concept to commissioning... and beyond," paper presented at SPE Intelligent Energy Conference and Exhibition at Utrecht, March 23-25, 2010.

3. Cheltout, Z.; R. Coupier, and M. Valleur, "Capture the long-term benefits of operator training simulators," Hydrocarbon Processing, April 2007, pp111-116.

4. Fiske, T. , "Benefits of dynamic simulation for operator training," Hydrocarbon Processing, December 2007, pp 17-17.

5. Glaser, D. C., "Put training back into operator training simulators," Hydrocarbon Processing, September, 2011, pp 41-43.

6. Hodgson, R. and P. Hassard, "Advanced drilling simulators offer realistic models to reduce crews’ learning curve," Drilling Contractor, July-August 2006, pp 50-54.

7. "Process optimization to grow 9%," Hydrocarbon Processing, October 2011, p 7.

8. Lippin, J. , "Preserving knowledge: Keys to effective lifecycle management," Hydrocarbon Processing, December 2011, pp 63-66.

9. Risvik, B. , "Hands-on drilling and well control training using drilling simulator," Statoil/ Well Informed, 4: 3.

10. Seki, T. et al, "Innovative plant operations by using tracking simulator, " paper presented at the SICE Annual Conference, University Electro-Communications, Japan, Aug. 20-22, 2008.

11. Sneesby, M., "Operator training simulator: Myths and misgivings." Hydrocarbon Processing, October 2008, pp 125-127.

12. "Drilling simulator reduces unplanned events," World Oil, December 2005, pp R9-R10.

The authors

TIINA M. KOMULAINEN is an associate professor in automation at Oslo and Akershus University College. Dr. Komulainen earned MSc and PhD degrees in chemical engineering from the Helsinki University of Technology, Finland. Previously, she worked with dynamic process simulation of large-scale industrial oil and gas processes at Kongsberg Oil & Gas Technologies . Dr Komulainen has research interests in pedagogical use of simulators and in modeling of chemical processes.

RONNY SANNERUD is professor of vocational education and training at Oslo and Akershus University College. Professor Sannerud teaches masters-level courses in vocational education and training, and supervising masters–level students. His current field of research is work-based learning/work-place learning.

BJARNE NORDSTEIN is a graduate process technician with work experience in the oil industry since 2003. In recent years, he has worked with upgrading the dynamic process simulator for Statoil’s Kristin field. He runs courses and the training of new or experienced process technicians, who work offshore, by using high-fidelity simulators.

HÅVARD NORDHUS is automation advisor at the Statoil Research Centre. He earned an MSc degree from the NTNU Department of Cybernetics Engineering. He has more than 20 years of experience in dynamic simulation of industrial oil and gas processes at Statoil. |

|