RICHARD PRICE, Polarcus Limited

|

| Polarcus’ Arctic-ready seismic vessels acquired 9,000 sq km of 3D seismic data about 645 km north of the Arctic Circle during 2012. |

|

Exploration is now being conducted in many environmentally sensitive sea areas of the world, and increasingly in Arctic waters, where minimizing the environmental impact of any activity is a high priority. Since 2008, Polarcus has built and introduced eight specialized seismic vessels. In building these vessels, the company placed specific focus on technologies relevant to operating in the Arctic offshore areas, where many national and international oil and gas companies are turning their attention in the quest for additional hydrocarbon reserves. In these areas, sources of environmental impact are severely regulated by the national authorities that grant permits for offshore operations, and all elements of exploration operations must have required mitigation technologies and procedures in place to meet the permit requirements.

A notable feature of the Polarcus vessels is the radical X-Bow design, which improves efficiency, reduces fuel consumption, and minimizes vibrations and noise radiation. This design is combined with the high ice class designations, ICE-1A and ICE-1A*, from the DNV classification society. These designations are indicative of a ship’s ability to safely navigate and function effectively in ice-covered waterways, and involves vessel features, such as hull strength, propulsion system requirements and winterization components. The vessels can operate in first-year ice of up to one-meter thickness without the assistance of icebreakers; they are ice-reinforced with thicker ribs and skin plates; have de-icing and ice-preventing systems at critical tanks and pipelines, and their propellers, gears and thrusters can withstand operations in ice.

Operational planning for Arctic projects must allow for the seismic vessel to navigate safely through certain ice conditions, such as transiting into an ice-prone area to deploy equipment when ice conditions permit, staying in the immediate vicinity of a survey area if ice moves in and out of the area, and staying as long as possible in an area before having to transit out in anticipation of closing ice conditions. These situations can only be addressed using a vessel with an ICE-1A classification or better, and they can have a significant impact on optimizing project performance and minimizing the time spent on location to complete the project.

EMISSIONS MITIGATION

In pristine Arctic environments, the mitigation of emissions from vessels takes on added importance. Polarcus vessels are equipped with specialized systems, which limit fluid, gaseous, solid and acoustic emissions to air and water. The technologies are particularly focused on minimizing emissions of nitrogen, carbon and sulfur oxides into the atmosphere, reducing noise and vibrations radiated into the water, the treatment of bilge water to achieve extremely high purity standards, and the elimination of any organisms in the ship’s ballast water before discharge, all of which are critical vessel features for Arctic operations. The vessels are also constructed with double hulls, a feature that significantly increases safety for operations in ice-prone areas, and eliminates the accidental discharge of fluids into the environment, should hull penetration occur.

To verify the emissions mitigation program implemented on the vessels, Polarcus worked with DNV to pioneer their Triple-ETM program (Environmental and Energy Efficiency), a voluntary environmental performance rating scheme for all ships. The program involves assessment of the environmental management practices, fuel efficiency, energy efficiency through design, and the monitoring and documentation schemes in use on the vessel. This assessment is followed by DNV verification of all performance factors and the declaration of the resulting Triple-E rating. Polarcus’ ICE-class vessels deployed in the Arctic have achieved compliance with the highest DNV rating, Level 1.

ENHANCED OPERATING PROCEDURES

The extreme and unique ambient climatic conditions, which occur north of the Arctic Circle, are such that operating procedures must be modified for activities in Arctic waters. The procedures must be aligned with specialized practices to ensure the safety and protection of people, equipment and all aspects of the environment in which the operation is carried out. In the case of seismic operations in Arctic waters, specific maritime, seismic and operational procedures must be developed and integrated into a practical management framework. To ensure safe passage through sea ice and safe operations in all open Arctic water conditions, Polarcus implemented a management plan based on a comprehensive suite of Arctic Operating Procedures, covering every operational aspect, including vessel-related practices, seismic activities and personnel management. These procedures were assessed, reviewed and qualified by the DNV as representing best practice for Arctic operations, in compliance with the highest standards in place today.

ARCTIC SEISMIC PROGRAMS

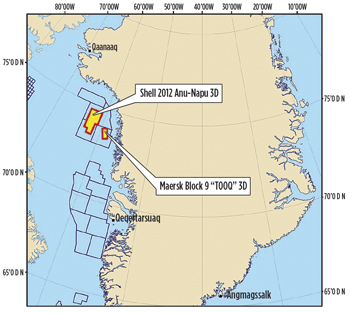

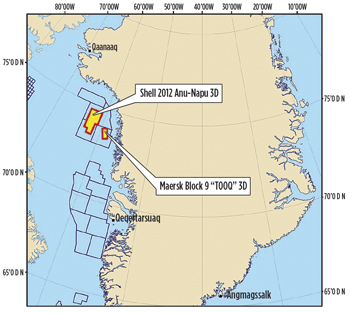

Polarcus received awards from two major oil companies for 3D seismic acquisition projects offshore Greenland for the 2012 summer period, Fig. 1. Although the Arctic operational capabilities of the Polarcus vessels, and the DNV certification of the company’s Arctic procedures, were of fundamental importance in raising the confidence level that the projects could be completed safely, efficiently and with minimal environmental impact within the short acquisition window, the extreme environmental conditions, existing within the Arctic Circle mandate that many specific operational criteria must be managed at a very high level. One of the most critical elements is ice management, requiring a comprehensive Ice Management plan.

|

| Fig. 1. During 2012, Polarcus conducted 3D surveys north of the Arctic Circle for Shell and Maersk offshore the west coast of Greenland. |

|

The two awarded projects totaled approximately 10,000 sq km in size, some 645 km north of the Arctic Circle off the west coast of Greenland, in an area covered by seasonal sea ice and subject to glacier calving in the summer season. Of all northern icebergs, 85% originate from the more than 100 glaciers of West Greenland, and between 10,000 and 15,000 icebergs are calved each year in the area, where the surveys are located.

Three of Polarcus’ high ICE Class vessels were utilized to acquire the seismic data, commencing operations in late July and completing the work two-and-half months later, in mid-October. During this period, the area was, to a greater or lesser extent, always affected by ice, comprising bergs, bergy bits and growlers. An Ice Management plan was of paramount importance to operational safety and efficiency. The detection of ice in all its forms in the survey area, the prediction of its movement, and the identification and tracking of ice that may pose a hazard to the 3D streamer spread, or that may cause an interruption to a survey line in progress, is a critical aspect of the management of a towed-streamer 3D operation in Arctic waters.

Ice Management planning implemented by Polarcus involved the integration of data from numerous remote information sources, such as daily ice reports from governmental agencies, commercial satellite imagery, and ice prediction services. Supplementing these data, and of paramount importance in the plan, were the active ice monitoring functions implemented on each vessel in the operation, including enhanced ice detection radar systems, one or more human specialist ice observers on the support vessels, and at least two ice “navigators” on each of the seismic vessels. The ice navigators were responsible for coordinating the Ice Management plan, and collating the ice forecasts and observational information from all active sources into a single ice management information system. This system allowed decisions to be made on ice hazards in the area, tracking of ice movements, predictions of areas of clear water, where survey lines could proceed with minimized ice risk, and forecasting of ice developments that may become severe enough to warrant the retrieval of the seismic spread. The Ice Management plan and the ice management philosophy implemented, of avoidance rather than interaction with ice, contributed significantly to the successful completion of the projects. No ice-related incidents were recorded, and high seismic production was achieved over the two-and-half month period of the operation.

Mammal impact mitigation. In addition to the ice monitoring, which was actively carried out on each vessel, another monitoring program for marine mammal impact mitigation was also in place throughout the duration of the project. Each seismic vessel was staffed with marine mammal observers, carrying out visual sweeps for the presence of marine life in the vicinity of the operations, and was also equipped with passive acoustic monitoring systems to detect any mammal vocalizations in the surrounding waters. With operating permit restrictions based around migration times, and seismic operations excluded from protected zones and reserves, these measures ensured that little to no impact occurred to marine life during the project, and no environmental impact incidents were recorded.

Logistics management. The remote location of the project area, combined with the extreme ambient climatic conditions, meant that logistics management was a critical element of the project plan. To ensure that a successful logistics framework could be established and maintained, a local shore base was set up in one of the settlements close to the survey area to provide a project office and hub from which all operational logistics could be managed. The impact of a logistics hub being located in a remote settlement could be very dramatic, and so the Polarcus and client shore representatives worked from this base, maintaining active and sustained communication with local community leaders before, during and after completion of the projects. As such, the community was engaged in the project in a positive way, and local businesses were supported, while rigorous journey management was employed to ensure that the operational footprint was minimized.

Logistical challenges included the management and control of 12 vessels and over 300 personnel, the provision of fuel, food, spare parts and consumables, and the preparation of emergency response procedures to address any incidents that may occur. Limited commercial transport was available in the project area, and therefore, specialized transport was arranged, including shuttle tankers to provide fuel and helicopters for crew changes and Medevac support. However, as helicopter availability could not be guaranteed; flying operations are often disrupted, due to poor weather conditions; and crew changes involving over hundred or more individuals were scheduled to take place every five to six weeks; the preferred mode of transport from the shore to the survey area was by one of the support vessels.

Onboard medical care. The difficulty and complexity of moving personnel to and from the survey operations highlights the issue of medical care onboard the vessels and the provision for medical evacuation should the need arise. In remote locations, it may take two or more days to transport a sick or injured person from an offshore vessel to the nearest onshore medical facility. In Arctic conditions, the delay may be even longer. Therefore, for remote Arctic operations, the Polarcus vessels are equipped to treat a wide range of immediate medical situations onboard.

For the Greenland projects, each seismic vessel had onboard a qualified doctor and a qualified medic, and the ships’ hospital facilities were upgraded and equipped to United Nations World Health Organization (WHO) Tier 2 standards. This compliance ensured that the onboard facilities were capable of not only providing immediate illness treatment, and first aid and injury stabilization, but also of taking X-rays and carrying out CRT scanning and dental intervention. In addition, telemedicine capabilities were implemented so that, if necessary, the onboard doctor could transmit diagnostic information to an onshore medical facility for further advice and direction. Should a Medevac situation have developed, it would either have been carried out using a support vessel, or a helicopter could have been mobilized and would have been utilized if there were conducive flying conditions. However, during the two-and-half months’ duration of the project, no recordable health or medical incidents occurred, and no Medevac was required.

SURVEY SUCCESS

The 2012 Arctic seismic program carried out by Polarcus successfully acquired over 9,000 sq km of high-quality seismic data over a 75-day period. Despite the complexity and challenges of conducting marine 3D seismic operations in ice-prone Arctic waters, zero recordable incidents were experienced, with no significant harm to personnel, marine life, vessels or equipment. Furthermore, the operational impact on the Arctic environment was minimized as a result of Polarcus’ decision to incorporate an environmental impact mitigation agenda into its core business strategy.

The author

RICHARD PRICE is vice president, Marketing & Business Development, North and South America, for Polarcus, based in Houston. Mr. Price graduated in 1973 with a BS degree in geology/geophysics and oceanography from the University of Wales in Swansea, UK. He has over 39 years of experience in marine seismic data acquisition. |

|