Intelligent well completions strategy increases thermal recovery in SAGD wells

Intelligent well technology and interval control valves were used to improve steam injection and production conformance in a thermal-enhanced oil recovery system in a northern Alberta SAGD well pair. A combination of zonal isolation, selective steam injection and monitoring can add substantial value to field developments, increasing energy efficiency and oil recovery.

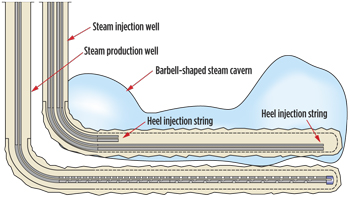

JOEL SHAW, Halliburton Bitumen is a thick, tar-like hydrocarbon that is often found in sandy formations. It is too viscous to flow in its natural state, so the steam-assisted gravity drainage (SAGD) system was developed to allow in-situ access to subsurface bitumen. SAGD involves drilling two parallel horizontal wells, one about 5 m above the other. The bitumen is too thick to flow initially, so there is a break-in period for both wells in which a work string is installed. Steam is either pumped down the string and back up the annulus or vice-versa, and the bitumen near the SAGD pair is heated. Once the immediate vicinity is sufficiently heated, production commences from the lower well and steam is injected into the upper well. As bitumen and water are produced from the lower production well, steam is injected into the upper production well, and a steam chamber forms.1 The steam chamber is actually an area of high-permeability sand from which the bitumen has already been extracted. Ideally, steam rises from the injection well evenly as a result of its low density and the high permeability of the steam chamber. The steam spreads horizontally as it rises and reaches the upper boundaries of the chamber. There, it condenses as the latent heat of condensation is passed into the tar-like bitumen. The bitumen’s viscosity is reduced as it is heated, and gravity pulls the fluids down to the production well, where it can be produced by conventional means. The steam chamber grows over time, as more and more bitumen is produced. ISSUES WITH TRADITIONAL SAGD SYSTEMS SAGD injection wells typically have been completed with dual strings in a slotted liner.2 One string ends at the heel, and the other ends at the toe. Steam can be injected independently into either of these strings, but only at two points—the heel and the toe. This can lead to a number of problems:

Current SAGD flow enhancements. In a homogenous formation, it would be ideal to inject steam over the entire length of the injector, and to produce condensed steam and bitumen evenly over the length of the producer. Devices have been designed to attempt this. While even steam injection is possible along the injection string, heterogeneity in the formation still causes uneven steam-chamber development, and changing the steam injection profile to react to the steam chamber is not simple. Outflow control devices (OCDs) or inflow control devices (ICDs) can be used to distribute the injection or production evenly across length of the well. These allow a predetermined amount of flow along the injection or production string at numerous points along the well. Unfortunately, these devices are either are un-adjustable or require a workover to change flow scenarios. They also create a pressure differential that can reduce the effectiveness of the steam. SOLUTIONS FOR SAGD SYSTEMS An ideal solution for an SAGD completion goes beyond the capabilities of a dual-zone completion, ICDs, or OCDs. It would:

Understanding the reservoir. Downhole pressure and temperature measurements, coupled with surface deformation measurements, are key components to understanding the shape and growth of the steam chamber as well as performance of the SAGD pair. These measurements can be used to infer a number of operational parameters of the formation and the well pair.

Control of injection and production. Controlling injection into, and production from, a formation requires two main components. The first provides selective communication from the string into discreet zones along the length of the completion. The second component provides compartmentalization between these zones.

ADVANTAGES OF ACTIVELY CONTROLLING SAGD A combination of tools to measure temperature and pressure, as well as control flow into and out of the formation, allows unprecedented management of SAGD systems. This includes improved knowledge of how the steam chamber is reacting and how well its growth is being controlled. Measurement and analysis of the steam chamber. In addition to traditional methods of estimating and qualifying the steam chamber, the ability to isolate zones allows better diagnostics and monitoring of the SAGD pair without need for workover.

Injection into specific zones. ICVs allow the injection profile to be changed repeatedly over the life of the well without intervention. Certain zones of the steam chamber can be temporarily or permanently closed if that area seems to be taking a disproportionate amount of steam or there is breakthrough. Using valves to shape the steam chamber. If the injectivity is not even across the length of the steam chamber, it can create a vicious cycle that gets worse over time. The section with greatest injectivity is typically an area with the largest effective diameter. Most of the steam will enter that section and cause the chamber to grow even more in that section. ICVs in the injection well can be used to break this cycle. The ICV in a high injectivity zone can be closed, while the adjacent valves are left open. Steam from the adjacent ICVs will rise and melt the bitumen above them. As this bitumen is produced, it will open up the steam chamber and increase the injectivity into the sections with the opened ICVs. Eventually, the injectivity between sections will be normalized, and normal injection can continue. In some scenarios, steam-chamber growth in certain directions has environmental or safety implications. For instance, if a SAGD field is near a water aquifer, it is important to keep steam from breaking through. Chamber growth can be controlled by closing the ICVs in sections that may break through to the aquifer. Elimination of breakthrough. An ICV can also be used in the producer to produce from specific zones of the completion. This method can be applied in situations when there is steam breakthrough directly from the injector to the producer. While an ICV can be shut on the injector to eliminate the breakthrough, it does not allow for further injection into that section of the steam chamber. Closing the corresponding ICV in the production well eliminates breakthrough while allowing steam injection into the corresponding zone. Increased injection pressure. Better control of individual zones improves production by allowing higher injection pressures. Selectively controlling injection points allows higher temperatures and pressures only where appropriate. It also allows for lower sub-cool and higher injection pressures without undue worry of breaking through to the producer.

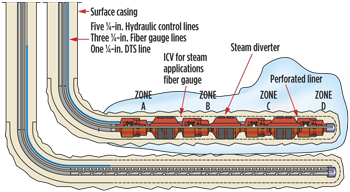

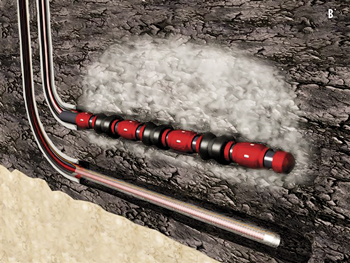

SOLUTION EXAMPLE A SAGD system in the Orion field of northern Alberta had been on line for a number of years.4 However, geological heterogeneity caused conformance issues. Technologies such as OCDs had been used in the field, but the formation’s lack of homogeneity would not allow for even chamber growth and bitumen production. The operator wanted to trial a surface-controllable ICV system to react to the unpredictability of the geology. They selected a candidate well based on a number of factors including established injector/producer communication, baseline performance data, and a producer that was equipped with DTS. The selected well pair had a history of sub-par oil production and SOR, so there was potential for improvement. Description of completion. The original dual tubing string completion was pulled from the injection well. The new completion is shown in Fig. 2. It consisted of:

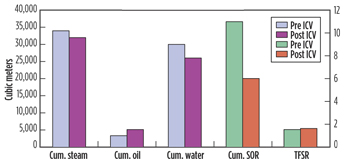

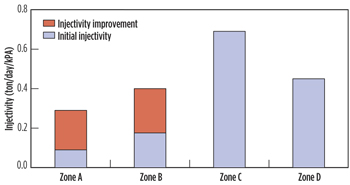

Torque and drag modeling was performed to ensure that the completion could be installed, and to ensure that the control lines would be intact once the completion was on bottom. Custom fluted centralizers were added at strategic locations in the tubing string to act as control-line protection. The steam diverters isolated the completion into four separate zones (Zones A-D) (Fig. 2), and the ICVs controlled the injection into each of those zones. The pressures in Zones B, C and D were measured using the fiber-optic gauges, while Zone A was measured at the surface through the annulus. DTS provided temperature reading in 1-m increments along the length of the injection and production string. The control lines were clamped at every tubing collar with dual-channel, heavy-duty line-protection clamps. Baseline analysis. Initial data were taken to calculate the injectivity and estimate the shape of the steam chamber. This was accomplished by injecting through each valve individually and watching in DTS. It was determined that Zones A and B exhibited poor injectivity, which indicated that the steam chamber had a shape similar to that represented in Fig. 2. The operator devised a steam-injection schedule to combat the poor performance of the steam chamber. This schedule was a monthly cycle that roughly consisted of three weeks injection into only Zones A and B, one week injection into all the zones, and one day shut in to take measurements. This injection schedule was designed to improve the injectivity and production from zones A and B, while maintaining Zones C and D. The desired effect was to increase the bitumen production without using excess steam and to improve the steam chamber conformance. Results. As published on the Alberta Energy Resource Conservation Board (ERCB),5 and shown in Figs. 3 and 4, there has been significant improvement in performance, when comparing the six months prior to the installation of the steam valve and the six months after its installation. In that time, the SAGD pair has exhibited a 45% improvement in SOR, and an almost 70% increase in bitumen production (Fig. 5). That represents an increase in bitumen from 3,000 cu m to 5,000 cu m, while the SOR has dropped from 11 to 6. This reduced the cumulative steam injected by 2,000 cu m. These numbers can be used to estimate the gain that has been realized by using the steam valve. Using $60/bbl for the price of bitumen, the increase in revenue can be calculated to be U.S. $1.5 million per year. The operator is now injecting solely into Zones A and B to further improve SOR and maximize production. The ICVs have proven to be highly reliable. They have each gone through approximately 50 to 60 full shifting cycles since their deployment in 2009. There have been no issues shifting the valves to date. Selective injection into specific zones has also allowed a temperature and pressure increase from 230°C to 260°C, and 2,700 to 4,700 kPa.

CONCLUSION The new completions strategy was successfully implemented in a SAGD steam-injection well and operated in temperatures up to 260°C. The mechanical reliability and integrity of the surface-controlled thermal interval-control valves and thermal feed-through diverters has been proven over the trial period. The fiber-optic monitoring systems have proven themselves to be valuable to the evaluation of the completion equipment and reservoir response. The baseline data gathered during the trial and close surveillance have improved the understanding of the well pair performance and its link to the geological heterogeneity. This has helped to identify the opportunities for conformance improvement and the building of a more uniform steam chamber. The completion is currently being used to modify the injection conformance in the well by injecting into one zone at the heel. The initial indications are of some warming of these zones, an improvement in injectivity, an improvement in SOR of 45%, and a 70% increase in bitumen production. This represents a U.S. $1.5 million/yr increase in production. LITERATURE CITED BIBLIOGRAPHY |

- Coiled tubing drilling’s role in the energy transition (March 2024)

- Using data to create new completion efficiencies (February 2024)

- Digital tool kit enhances real-time decision-making to improve drilling efficiency and performance (February 2024)

- E&P outside the U.S. maintains a disciplined pace (February 2024)

- Prices and governmental policies combine to stymie Canadian upstream growth (February 2024)

- U.S. operators reduce activity as crude prices plunge (February 2024)