|

Aberdeen-based Churchill Drilling Tools, focused on delivering innovative systems for the drilling and completion sectors, achieved a 100% reliability target for its Smart Dart system in 2011, which enabled it to ramp-up production. The company will invest £500,000 (US $909,000) to expand production offering and workforce at its Crombie Road facility over the next two years.

Central to the company’s expansion is its Smart Dart activation technology and its flagship product—DAV (dart-activated valve) MX. The system uses darts, not balls, because they are quicker to set, more reliable, simpler to use, more versatile, HPHT-resistant, and usable at high angles. A range of Smart Darts control the opening of the DAV MX valve. The Smart Dart connections feature dual-shear systems, sealing and multi-point latching. The MX (mechanical extrusion) system is based on shear pins situated inside the darts.

Smart Darts are the key to unlocking the potential of a simple CircSub to deliver reliable and versatile bypass on demand. Whatever the drilling application, whether planned or contingency, the DAV MX system provides rapid and reliable switching to the optimal flow path configuration.

|

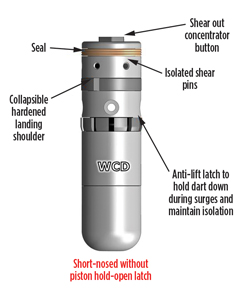

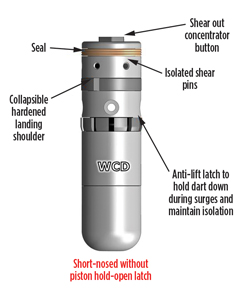

| Components of the WCD Smart Dart |

|

|

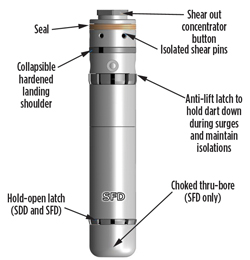

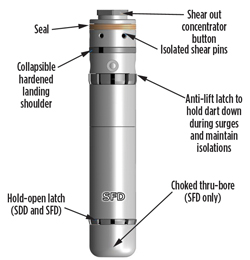

| Components of the SFD Smart Dart |

|

PROCEDURE

The DAV MX valve assembly is normally placed in the BHA below the drill pipe. Until required, it remains dormant and closed. A Smart Dart is pumped into the valve, seating in the piston and depressing the spring to open the ports in the required mode. The valve is universal and accepts any of the darts supplied. After circulating is complete, a universal closing dart is pumped to shear out the Smart Dart and close the valve. Below the valve is a catcher sub which stores the used darts in a central core. Around the core is a large inner annulus that allows flow around the darts so that drilling can resume after cycling.There are multiple dart options and the valve accepts any of the darts in any order. Each dart is used just once; multiple darts are necessary for multiple cycles.

DART TYPES

Each tool comes with a range of Smart Darts. The different darts configure the valve in different flow paths according to the application.

The Standard Diverter Dart (SDD) is the dart of choice for most drilling applications.

When pumped into place, the SDD holds the ports open and blocks off the through-bore to the BHA below. When the pumps are off, the ports of the valve remain open. With the versatility of offering multiple applications, the SDD is also a time saver for tripping dry to surface and or jetting BOPs. It also prevents lost-circulation material (LCM) from contaminating the BHA.

Unique latching of the Split Flow Dart (SFD) ensures that the valve remains held open at all flow rates and pressures, so it can be used at depth and near surface as it is immune to varying hydraulics with no need for tool pre-configuration. Like the SDD, the SFD holds the valve open with pumps off. Unlike the SDD, the SFD has a choked bore, which allows pressure and flow to and from the bit. For some applications full-pressure relief is preferable, particularly when moving in and out of hole. In addition, the knowledge that there is flow to bit can give better hole cleaning performance. The ability to keep the BHA cool whilst agitating flow by spinning the pipe, maximizes hole-cleaning whilst and safeguards expensive jewelry.

The Well Control Dart (WCD) latches down and seals, so that there is no flow path into the drill string from either the bit or the annulus. It allows the valve to withstand external pressure and then commence bypass when the pumps are on. It will give 100% bypass of the BHA when pumping, but with pumps off, the ports will shut out the annulus with the dart remaining securely latched and sealed onto its seat.

A Universal Closing Dart (UCD) is used to shear out any of the Smart Darts. The closing dart hits the concentrator button to close the valve quickly and easily.

|

| Smart Darts have become a reliable option for switching a variety of drilling and completion functions. |

|

RELIABLE PERFORMANCE

The DAV MX dart-activated valve achieved 100% reliability last year and is a major development in drilling bottomhole assemblies. Using the tool, the bypass process becomes more efficient and effective. It is up to four times faster than the traditional technique involving extruding balls.

“Throughout 2011, the DAV MX retained its pressure integrity, opened with every opening dart and closed with every closing dart. This is a major achievement in a drilling environment,” said Andy Churchill. “It is always tempting at the beginning of the product life-cycle to go into full-scale production after just a few successful runs; however, our customers drill in many different environments.”

“To support these product lines we have recruited in all areas of the business—from supply chain management, right through to customer service—which has taken our staff up to 20 in Aberdeen. It’s important to us that our equipment offers performance and reliability in any well, whatever the length, angle, depth, pressure or temperature, so we have invested a lot of resources in research and development and in monitoring tool performance. The results speak for themselves.”

The company is further developing its global servicing infrastructure while supplying downhole drilling valves in Europe, North America, and the Far East. It is also extending its portfolio into additional markets. Co-director Mike Churchill explained, “The team has been able to identify other applications for this dart technology and then convert them into new formats, including float and pressure testing equipment. We are very excited with the results so far and have already had a successful run in Norway in the pressure testing category and we expect to be launching further new lines in 2012.”

With more than a decade of hydraulic design experience, Churchill Drilling Tools has produced a range of patented performance and safety improvement technologies, used by more than 50 operators worldwide.

|