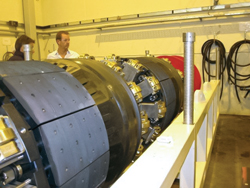

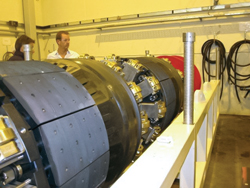

TDW Offshore Services AS has designed and built a customized 48-in. SmartPlug pipeline pressure isolation tool to facilitate maintenance of Nord Stream AG’s twin pipeline system. Weighing approximately 12 tons, it is the largest SmartPlug tool ever produced.

Nord Stream retained TDW to assist in developing contingency solutions for pipelay, pressure testing and planned future maintenance of the Nord Stream gas pipelines. Upon completion, the two 48-in pipelines will extend about 1,220 km from Vyborg, Russia through the Baltic Sea to Lubmin near Greifswald, Germany. TDW carried out a series of pre-engineering studies before finalizing the design. The SmartPlug tool was designed, built and rigorously tested by TDW at its global headquarters in Stavanger. The new 48-in. SmartPlug tool will be used to safely isolate pipeline pressure during scheduled pipeline maintenance and potential valve change-outs. It is currently Type Approved by Det Norske Veritas for a maximum operating pressure of 199 bar.

“The tool design is based on our proven 42-in. SmartPlug design,” said Larry Ryan, director of operations for TDW Offshore Services. “However, the exceptionally large diameter of the pipeline meant that Nord Stream required a tool that was 30% larger. The new SmartPlug tool is not only exceptionally large, but is also capable of isolation at extremely high pressures.”

|

| The industry’s largest 48-in. SmartPlug pipeline pressure isolation tool was custom built for Nord Stream’s twin pipeline system from Russia to Germany. |

|

The SmartPlug pipeline pressure isolation method is designed to provide significant value to owners and operators of pipeline systems. It makes it possible to safely isolate the area targeted for work from hydrocarbons without bleeding down the entire work zone, which is costly and time-consuming. In the case of Nord Stream, there are no mid-line valves available for use, so the entire pipeline would have had to be depressurized, taking a significant amount of time. Given the minimal amount of gas released while isolating a work area, the new SmartPlug tool offers more than economic benefits. It is also very effective in minimizing impact on the environment.

TDW Offshore Services is a subsidiary of T.D. Williamson, which provides pipeline equipment and services worldwide. T.D. Williamson offers a comprehensive portfolio of safe integrity pipeline system solutions for onshore and offshore applications, including hot tapping and plugging, pipeline cleaning, integrity inspection, pigging and non-tethered plugging pig technology for any pressurized piping system.

Nord Stream AG plans to provide a transport capacity of about 55 Bcm/year upon completion of the second natural gas pipeline in the last quarter of 2012. Russian OAO Gazprom holds a 51% stake in the joint venture. The German companies BASF SE/Wintershall Holding GmbH and E.ON Ruhrgas AG hold 15.5% each, and the Dutch gas infrastructure company N.V. Nederlandse Gasunie and the French energy company GDF S.A. each hold a 9% stake.

|