Pramod Kulkarni, Editor

|

|

Gerald Schotman was appointed as Chief Technology Officer and Executive Vice President of Innovation and R&D at Shell in 2009. In that role, he is responsible for developing Shell’s overall technology strategy, as well as for the creation and deployment of new technologies for particular projects. He graduated as a civil engineer from Delft University of Technology in the Netherlands and joined Shell as a research engineer in 1985. He has held technical and commercial positions and worked on assignments in the UK, Brunei and Oman before becoming Vice President for Strategy within Shell Exploration and Production in 2006.

How do you foster innovation in a multinational oil and gas company that faces complex challenges from upstream E&P to downstream processing and transportation? Optimum solutions can no longer be developed within a narrow technology silo; rather, it is necessary to expose a particular problem to a large number of creative minds within the organization as well as bring in innovators from other spheres.

Shell has approached this goal through a new central organization called Projects and Technology (P&T) that integrates both upstream and downstream R&D. Within this organization, a Technology Solutions and Deployment group is responsible for applications engineering, and a Project Execution group is responsible for supplying everything from drilling rigs and production platforms to refining and petrochemical plants and for building transportation infrastructure such as pipelines and LNG tankers. Gerald Schotman, Shell’s chief technology officer, explained the goals and implementation of the new P&T organization in a recent interview with World Oil.

|

|

World Oil: Why the need for a new organization?

Gerald Schotman: Shell has been a company of technology firsts since 1892, when the first seagoing tanker brought a shipment of kerosene through the Suez Canal to markets in the east. Since then, we have helped develop 2D seismic in the 1920s, the Archie equation in the 1940s, 3D seismic in the 1980s and smart fields in the 2000s.

But now the industry faces new challenges, and we needed a new organization that is able to deliver fully integrated solutions using our proprietary technologies and technical capabilities and leveraging third-party products. The new organization was initiated in 2009 under the direction of CEO Peter Voser. Previously, many of these activities were spread across the entire Shell group.

Six pillars support P&T: R&D, technology solutions and deployment, project execution, well engineering, technical IT and engineering. We used to carry out R&D separately within the E&P, downstream and Gas & Power businesses. Now we have one R&D organization that can develop solutions that are fully integrated along our entire value chain. Similarly, we have brought Technology Solutions and Deployment as well as Project Execution into the P&T organization to allow standardization of design and equipment and to apply the best practices across the group. Now we can truly “design one, build many.”

WO: What will be the nature of technology development in P&T?

Schotman: Our technology portfolio will consist of developing core technologies by faster development and greater focus on replication, achieving technology firsts through big breakthroughs focusing on value, and high-risk, high-reward emerging technologies by focusing on longer term investments. We want to create an incubator for new ideas to develop game-changing technologies.

WO: What are distinct advantages of the new P&T organization?

Schotman: One advantage is that we’ll be able to leverage a technology developed in one area of the world for adoption in another part of the world. Our central R&D organization supports communication and idea exchanges to facilitate such interaction. We’ll also be able to take advantage of our global scale to achieve cost efficiencies in equipment sourcing and procurement as well as implement standardized solutions and best practices throughout the organization.

WO: How does combining upstream and downstream project execution help?

Schotman: We tend to have smaller projects in downstream that are associated with upgrades to refinery and petrochemical plants. Downstream megaprojects come typically in a four-year cycle. In upstream, however, we typically deal with megaprojects. Our goal with creating a single organization that delivers on both upstream and downstream projects is to leverage the downstream project groups’ skills into the smaller upstream projects, and apply megaproject capability where it has the greatest impact.

WO: What are the goals of the Innovation and R&D group?

Schotman: IR&D is charged with developing differentiating technologies with application within a two- to over 20-year time horizon. This includes the development of game-changer technologies needed to create new future businesses. On the other hand, a subgroup, such as Global Solutions Upstream, focuses on projects with less than a two-year time horizon. For instance, GSU implemented recently existing technology in Saleym, Western Siberia, to monitor and control 800 ESPs from one control center, thereby eliminating the need for our crews to drive long distances in sub-zero weather to manually turn a well on or off.

WO: What about improvements in well construction?

Schotman: Our Wells division, consisting of Well Engineering and Completions and Well Interventions, is already recognized as being top quartile. To sustain our standing, we have to accelerate the field implementation of R&D innovations. We’re already achieving significant improvements.

For example, we drilled wells in the Qatar North Field in record time for the Pearl gas-to-liquids project in less than 75 days and completed them in as little as 28 days, with an average of 45 days per well. We performed perforation, stimulation and cleanup tasks simultaneously to save about 20 rig days per well. Because the North Field is sour with prolific production rates, this simultaneous operation was a world first.

WO: How are you planning to bring in innovation from other technology companies?

Schotman: We feel there are a wide range of opportunities for collaboration within our industry, and with universities and even technology companies that are outside the oilfield realm. Our nine chief scientists have roles in joint industry projects.

For instance, we have a collaborative project underway with the Massachusetts Institute of Technology, which is not known for oilfield technology. Another collaborative project is with Hewlett-Packard in developing an extremely high-resolution seismic data acquisition system that will be a significant leap forward in seismic data quality (see sidebar). We never decline an opportunity to discuss technology and are open to shining a light on potential blindspots.

WO: What will be the role of Shell R&D laboratories throughout the world?

Schotman: We encourage collaboration throughout our R&D network, but certain of our laboratories will continue to have niche roles. For example, our Technology Center in Oman will continue to engage in enhanced oil recovery technologies. The Calgary research center will continue to focus on oil sands technology developments. The new technology center in India has a staff of 500 developing innovative technologies associated with managing emissions and carbon capture and sequestration.

WO: What is Shell doing in terms of technology for shale development?

Schotman: We’re in the process of developing differentiating technology to improve the identification of sweet spots in shales and improve production efficiency through advances in fracturing. We have already made advances in reducing well costs through our drilling optimization effort in the Pinedale Field in Wyoming.

WO: What is the one emerging technology that will make a major impact on oil and gas activity?

Schotman: One example that springs to mind is fiber optic technology. It has innumerable applications, ranging from acoustic sensing to temperature, pressure and fracture monitoring in real time. I don’t think we have seen the limits of this technology.

| |

|

SEEKING A PARADIGM SHIFT IN RESOLUTION

Dirk Smit, Shell’s VP of exploration technology and chief scientist for geophysics, feels that current exploration sensing technology can still lead to incorrect drilling target selections, resulting in dry holes. He says Shell is on the verge of a paradigm shift in exploration: “Similar to Moore’s law in computing, it is now possible to achieve an order-of-magnitude increase in sensing, resulting in better data quality at a lower cost.”

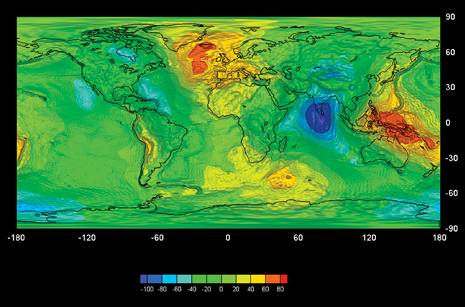

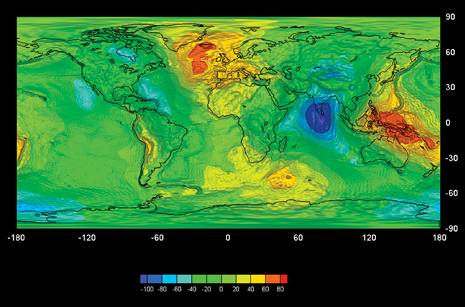

During a recent presentation in Houston, Smit showed a high-resolution gravity field map processed from data acquired by the European Space Agency’s Gravity Field and Steady-State Ocean Circulation Explorer (GOCE) satellite. Shell has developed map products using a combination of the GOCE gravity data with airborne data. These map products have resulted in the discovery of several new basins that had been previously overlooked due to resolution limitations.

Smit presented an interpreted gravity map that showed how the continents of Africa and South America fit together about 180 million years ago in a landform called West Gondwana. The continents started drifting apart about 130 million years ago. Fossilized plants and animals from the same geologic time period are found in both eastern South America and western Africa. Shell is among the oil and gas companies studying this common geologic heritage through high-resolution gravity and magnetic data for a better understanding of the basins and their hydrocarbon reservoirs.

Shell is also working on the development of a high-resolution reservoir internet of sensors with real-time interaction capability (see exploration column, page 15).

Shell is using high-resolution gravity mapping from data like this acquired by the European Space Agency’s GOCE satellite to investigate several sedimentary basins that were previously overlooked.

|

|

|