DAVID A. GRAY, TAM International

New research suggests that methane contamination blamed on fracing is actually due to cement integrity issues that can be inexpensively controlled.

|

| Drilling operations in the Marcellus shale of Pennsylvania, Photo by Michelle Dodd, courtesy of Chesapeake Energy. |

|

Efforts in many cities, states and countries to ban hydraulic fracturing as an oil and gas production method have been driven in part by a few well-publicized reports of high methane content observed in drinking water near shale production operations. Although methane gas is not regulated in drinking water—not being considered harmful to drink—this gas is a concern because it can accumulate and potentially cause suffocation and/or explosions.

One recent study sampled drinking water in Pennsylvania and New York and reported nearly 17 times as much methane in drinking water sources within 0.6 mi (1 km) of newly drilled, completed and fractured shale gas wells compared with sources located more than 1 mi (1.6 km) away.1 Assuming that the testing was conducted in a valid process, these results would qualify as definitive information that linked drilling and completion of some shale gas wells to increased methane content in shallow aquifers. However, the same study reported that no chemicals used in hydraulic fracturing fluids were detected in drinking water samples. This suggests that, contrary to fracing opponents’ claims, the newly created fractures are not extending thousands of feet upward into the shallow freshwater aquifers.

A number of industry studies suggest that shallow gas migration, from formations far above the fracture-stimulated shale formation, may be responsible for the occasional aquifer contamination that has widely been blamed on fracing in shale oil and gas operations. The inexpensive addition of a mechanical device, specifically an inflatable or swellable casing annular packer, to control annular fluid movement after cement displacement can improve cement integrity and greatly reduce or eliminate the possibility of annular gas migration that could potentially enter drinking water formations, leak to the surface or create sustained casing pressure. This article presents examples of this application and argues that the use of casing annular packers should be evaluated and included in any well drilling program risk analysis.

CEMENT INTEGRITY

The typical oil or gas well is constructed by drilling through thousands of feet of rock and cementing in place multiple strings of casing. In shale wells, the vertical section generally terminates near the target reservoir, and the well path is then turned horizontally and penetrates thousands of feet into the shale formation. An additional casing string or liner is then run into the well and the horizontal segment is separated into multiple producing zones through various methods such as cement or packers. The space between different casing string sizes, or between the casing and the formation, is called the annulus. Cement is used to fill the annulus between different casing string sizes, for stability and to provide pressure barriers; the integrity of the cement is critical in controlling the pressure and the flow of the various fluids in the well.

Thousands of these types of wells have been safely drilled, completed and produced worldwide. Only a few specific geographic areas are experiencing the water aquifer contamination problem. An improved understanding of the regional geology can better define the potential sources of unwanted gas flow, and wellbore completion equipment can be designed to prevent contamination of drinking water aquifers.

Efforts to define the cause of elevated methane levels are still underway, but one problem that has plagued oil and gas drilling for some time is a lack of cement integrity. This loss of control can occur during the initial completion, during the high-pressure fracturing process or later in the life of the well due to corrosion or tectonic movement.

Gas migration through the annulus is generally considered a major contributing factor in the lack of cement integrity during initial completion. Numerous studies have been conducted and articles written as to the causes of this migration. Multiple solutions to prevent the occurrence have been presented.

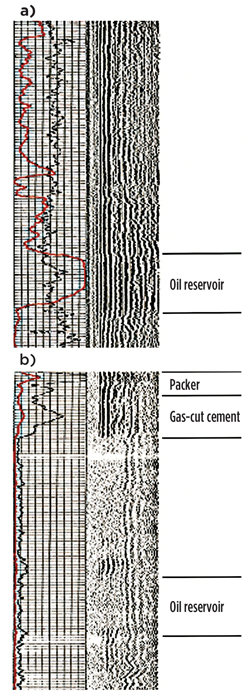

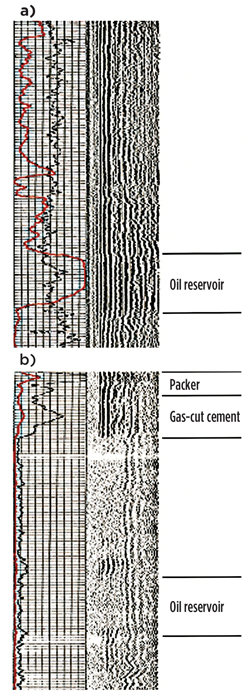

In one study designed to investigate the reasons for this initial gas migration, multiple pressure gauges were placed on the outside of casing and hardwired to the surface to allow monitoring of annular pressure at various depths in the well during critical operations—while circulating, while displacing cement and during the cement curing process.2 After displacing cement and bumping the plug, pressure in the annulus declined, Fig. 1a. In the cases where the annular pressure fell below formation pressure near the gauge, loss of hydraulic bond was observed during the completion phase, in many cases requiring costly repair before producing the well. If left untreated, this poorly bonded area would allow gas flow from higher-pressure zones to lower-pressure zones in the well.

|

| Fig. 1. Annular pressure vs. time a) for a conventional cement job and b) for a cement job with a casing annular packer added. |

|

Figure 1b shows the annular pressure response when a casing packer was run and an annular seal was achieved immediately after plug bump. In this case, the annular pressure below the casing annular seal declined rapidly to a level that was less than the nearby formation pressure. Gas flow was determined by neutron log analysis as an accumulated pocket underneath the annular seal. As the decline and flow occurred very early in the curing process, equilibrium pressure was achieved quickly at the formation face. This rapid pressure equalization provides a better environment for the development of high-quality cement, eliminating conditions for long-term gas flow or fluid loss. The objective was achieved: a cured cement column without flow channels.

CASING ANNULAR PACKERS

Solutions to controlling annular gas migration are available from many different service companies; to be effective, these solutions must be custom-engineered for the geological and environmental conditions present. Mechanical devices with elastomeric seals such as inflatable or swellable casing annular packers are commonly used. Chemical formulations used to improve cement properties can also be successful under certain well conditions.

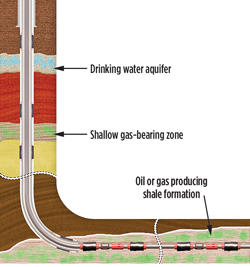

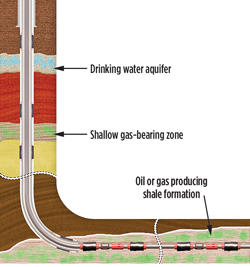

In several geographic areas of unconventional resource development, thin, shallow formations containing non-commercial levels of methane gas are encountered in the vertical well section, Fig. 2. These shallow formations are often considered a contributing factor to the occurrence of annular gas migration and/or the lack of cement integrity in the intermediate casing strings. In an unreported, recent study of wells in Pennsylvania’s Marcellus shale, seven of 10 wells exhibited poor cement integrity of intermediate casing. In the same development area, the operator elected to use casing packers as a method of controlling annular gas migration. With this method, the operator achieved a 100% success rate of maintaining cement integrity before and after drilling and completion.

|

| Fig. 2. Typical horizontal well diagram showing a shallow gas sand. |

|

In multiple wells where a full-length production casing has been run in the horizontal section, there are still indications that nearby drinking water sources contain higher methane levels than normal. This data further suggests that the methane source may be from the naturally occurring, thin formations in the vertical section of the well. If these formations contain methane, they have potential to flow into the well annulus and cause a loss of cement integrity of the intermediate casing. This seems to be a more plausible source for the surface methane than the horizontal drilling or fracing processes.

Methods offered by service companies to address annular gas migration vary from mechanical devices such as casing annular packers (inflatable, compression-set or swellable) to chemical additives for modification of cement slurries. Both methods are designed to achieve an annular seal immediately after the cement is displaced or to artificially maintain hydrostatic pressure that restricts upward movement of fluids (gas, oil or water) in the annulus that can destroy cement integrity.

The successful use of casing annular packers to control annular fluid migration has been well documented. The case studies demonstrate a near-100% success rate of eliminating annular fluid flow and improving cement integrity in surface, intermediate and production casing strings.

In 1986, an investigation was begun of poor cement integrity due to annular fluid migration, leading to the application of inflatable casing annular packers immediately after cement displacement and plug bump in shallow wells north of Houston.3 Eleven of 14 wells required cement repair prior to fracturing in wells constructed without casing annular packers. An additional 31 wells were drilled and cemented with a packer placed within 50 ft (15 m) of the formations containing gas. The study involved running cement bond logs and neutron logs for pre-frac analysis, and radioactively tagging the frac sand and running a gamma ray log after fracing. A success rate of 100% was achieved based on the criteria that no cement repair be required and that radioactively tagged frac sand never be detected out of the target reservoir.

In a typical cement bond log run on a well completed without a packer, very poor cement bonding is seen above the oil zone to be treated, Fig. 3a. Completions and hydraulic fracturing operations were undertaken without repairing the poor cement bond. Poor stimulation ratios were observed due to loss of frac fluids upward, alongside the casing. In contrast, a typical cement bond log on a well completed with a packer shows excellent bond quality above and below the packer with a disturbed region immediately below it, Fig. 3b. Analysis of the neutron log determined that the area contained a high level of gas.

|

| Fig. 3. Typical cement bond logs from wells constructed a) without and b) with a casing annular packer. |

|

In another case study, an E&P area in Indonesia had encountered severe annular gas flow problems for years. The problems ranged from less-severe sustained casing pressure to rig evacuations, blowouts and even multiple rig fires. Due to the severity of the problem, the operator adopted the use of a mechanical control method in 2001. Since then, more than 300 wells have been successfully drilled and completed, with minor annular flow problems in only three of the wells. All three of these problems were repaired with inexpensive and effective standard intervention programs. No annular flow was severe enough to require rig evacuation, and no blowouts were experienced.4

In two other areas (the Gulf of Mexico and the Gulf of Thailand) where operators experienced catastrophic annular flow problems, casing annular packers were added to the completion program, and now wells are successfully drilled and completed with no annular gas flow, sustained casing pressure or other problems.5,6

The recent introduction of casing packers constructed with swellable elastomers simplifies the completion process and has greatly improved cement integrity in a wide variety of wells. This device is now accepted as a reliable stand-alone zonal isolation method in horizontal sections to allow selective fracturing of individual zones.

ACKNOWLEDGMENTS

The author thanks C. O. “Doc” Stokley for his contribution to this article.

LITERATURE CITED

1. Lustgarten, A., “Scientific study links flammable drinking water to fracking,” ProPublica, May 9, 2011.

2. Cooke, Jr., C. E., Kluck, M. P. and R. Medrano, “Field measurements of annular pressure and temperature during cementing,” Journal of Petroleum Technology, 35, No. 8, August 1983, pp. 1429–1438.

3. TAM International, “Field study of annular gas migration,” brochure, 1986.

4. Brooks, R. Newberry, J. Cook, P. and F. Wendlinger, “Preventing annular gas flow in conjunction with 2 stage cementing,” SPE 116447 presented at the SPE Asia Pacific Oil and Gas Conference and Exhibition, Perth, Australia, Oct. 20–22, 2008.

5. Shiflet, N., Dion, M. O. and D. P. Flores, “A practical solution to control gas migration,” AADE-05-NTCE-71 presented at the American Association of Drilling Engineers National Technical Conference and Exhibition, Houston, April 5–7, 2005.

6. Tiraputra, P., et al., “Overcoming shallow-gas drilling difficulties in the Gulf of Thailand,” IADC/SPE 87179 presented at the IADC/SPE Drilling Conference, Dallas, Texas, March 2–4, 2004.

THE AUTHOR

|

|

DAVID A. GRAY joined TAM International in 2010, in the newly created position of Director for Global Business Development. His responsibilities include coordinating business development activities with major clients and business partners globally. He has more than 30 years of field operations and management experience within the oilfield services industry, including companies such as Halliburton and Weatherford. Mr. Gray holds an engineering degree from the University of Alabama and an MBA from the University of Texas at Austin.

|

|