Giga-cell simulation improves recovery from giant fields

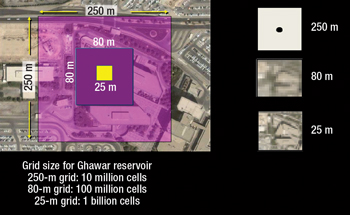

To demonstrate the benefits of its new high-resolution reservoir modeling software, Saudi Aramco used it to refine existing mega-cell models of the world’s biggest onshore and offshore oil fields.Ali H. Dogru, Saudi Aramco High-resolution geological models built using seismic, geological and engineering data are often upscaled to smaller-size flow models for reservoir simulation. It is well-known that reservoir heterogeneities play a very important role in reservoir behavior. Due to upscaling, these heterogeneities are lumped into average rock properties. Therefore, upscaled simulation models only provide average reservoir performance rather than actual. In general, vast amounts of seismic, geological and engineering data are available for the large reservoirs of the Middle East. If high-resolution seismic data were used, these geological models could be in the order of billions of cells. In practice, due to the limitations of reservoir simulators, these high-resolution models are upscaled to a few million cell flow models. Saudi Aramco is using a new parallel reservoir simulator, which runs geological models without or with minimal upscaling, to simulate these Middle Eastern reservoirs—some of the world’s largest with some of the longest production histories—using more than 1 billion cells in practical times. This technology provides highly detailed pictures of the activity inside the reservoirs, capturing the movement of fluids. INTRODUCTION Saudi Aramco uses reservoir simulation technology to manage its vast hydrocarbon reservoirs and had relied almost entirely on commercial simulators until 2000. The average number of grid blocks (cells) used for the black oil simulation studies in the 1980s was in the vicinity of 10,000, and it climbed to 150,000 by 2000. The average grid block size varied between 0.25 km and 1 km, with the vertical number of layers ranging from 10 to 15. These simulations were highly upscaled from the geological models, which contained several million cells and far more detail. In 2000, Saudi Aramco introduced a new, in-house parallel reservoir simulator that increased model size to more than 1 million cells.1 The Parallel Oil, Water and Gas Enhanced Reservoir Simulator (POWERS) provided an average grid cell size of less than 0.25 km, ranging down to about 0.08 km. The minimum number of vertical layers also increased from 10 to 100. These high-resolution models were used in relatively small fields, and demonstrated success locating bypassed oil and guiding engineers to drill in specified locations for increased recovery.2,3 Continuous improvement brought the simulator’s model size to about 30 million cells by 2008. NEED FOR HIGHER RESOLUTION This “mega-cell” reservoir simulation technology still lacked the capability to account for log-scale and seismic-scale heterogeneities. The ability to provide that level of resolution for some of the world’s largest reservoirs, like Ghawar Arab-D, would have major economic implications. However, it would require a much more powerful parallel reservoir simulator. Figure 1 illustrates the role of areal grid size in capturing reservoir heterogeneity. As shown, an areal square grid of 0.25 km (250 m) covers an area composed of two large office buildings, a parking lot, walkways, trees and a garden. This area is represented by a single “dot” when used as a grid block, as shown at the top right of the figure. In terms of reservoir simulation, this means that any rock heterogeneities within this block are indistinguishable. This grid size would require 10 million cells to simulate the entire Ghawar reservoir with 32 vertical layers.

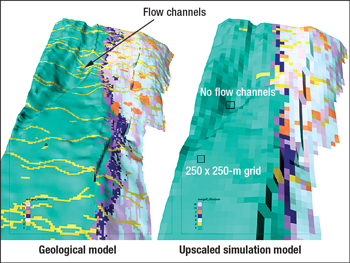

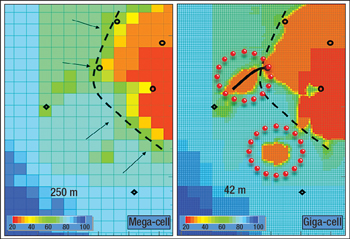

If the grid block size is reduced to 80 m, the grid will cover about two office buildings only. The corresponding image on the right shows that the same 250 x 250-m square now has significantly more information than the single dot provided by the 250-m grid size. The 80-m grid size would require 100 million cells to simulate the Ghawar reservoir with the same number of vertical layers. If the grid block size is further reduced to 25 m, which is seismic scale, the image becomes much clearer. Conceptually, this means that a 25-m simulation grid can capture more reservoir heterogeneity. This grid size would require 1 billion cells to simulate the entire reservoir. ADVANTAGES OF GIGA-CELL MODELING The next generation of Saudi Aramco’s in-house parallel simulator succeeded toward this end, and enabled the simulation of two giant reservoirs by an excess of 1 billion cells for the first time, covering 60 years of production history involving many producer and injector wells.3,4 These two reservoirs (Safaniya, the world’s largest offshore, and Ghawar, the world’s largest onshore) were simulated in seismic grid size (15–42 m) within practical simulation times (15–33 hr). The official user version of the billion-cell simulator, dubbed GigaPOWERS, was completed and launched in January 2010.3 The simulation time required continues to decrease with the use of new cluster computers, with a target to reduce it to 8 hr—an overnight run. Areal resolution. Once consequence of the loss of heterogeneity that occurs in upscaled models is that fluid movement between wells is largely misrepresented. Although well pressures, watercuts and gas-oil ratios (GORs) can be matched at wells with the upscaled models, distribution of oil and water within the reservoir (between the wells) cannot be. Flow channels in the geological model disappear in the upscaled model, so actual flow patterns in the reservoir cannot be simulated, Fig. 2.

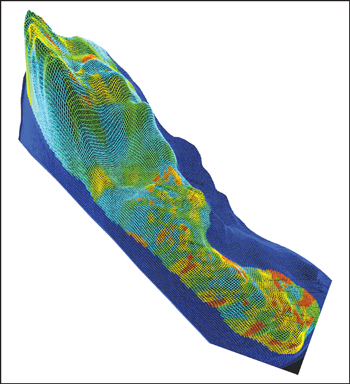

However, if the geological model can be simulated intact, using as many cells as required to maintain all data integrity, the resulting reservoir model would adequately capture fluid flow within the reservoir. Vertical resolution. High-resolution grid models should have a sufficient number of vertical layers to capture vertical heterogeneity. Ideally, log-scale layering on the order of 1 ft would capture all the vertical heterogeneity;2 however, this level of resolution increases computer time. As a compromise, proper upscaling can be applied to select layers while still capturing vertical heterogeneity. This is important in capturing water and gas fingers. Figure 3 shows a field case with near-log-scale vertical layering in an offshore carbonate reservoir with 30 years of production history. Water is represented by the blue coloring and oil by orange. Based on the well log information, the lower oil zone was covered by a thin water layer in the lower portion of the reservoir. Similarly, well logs had shown the existence of several thin water fingers in the eastern and western fronts.

In order to capture the well information and simulate the movement of water fingers in the reservoir, near-log-scale layering was needed. This layering yielded satisfactory history matching for the water arrival times and watercuts at the wells. Had thick layering using strong vertical upscaling been used, water arrival times and watercuts could only be matched by introducing nonphysical permeability multipliers and pseudo-relative permeability functions. In this example, rock relative permeability curves were used without any alterations, and only slight adjustments were made to the rock permeability, preserving the measured lab and field values. Numerical solution accuracy. An accurate numerical solution is important for calculating the movement of water and gas inside the reservoir. When large grid blocks are used, pressure fields in the reservoir cannot be accurately computed. This will affect the simulated fluid velocities, saturations and breakthrough times. Large blocks will smear the advancing fluid fronts, often predicting premature fluid breakthrough at the wells due to numerical dispersion.4 To match the water and gas arrivals at the wells, reservoir engineers often introduce pseudo-relative permeability functions and permeability modifiers. For example, using a 0.5-km grid, for a 1-km well spacing, only one grid block can be placed between the wells, so the pressure field calculated will be very approximate. If a 0.25-km grid is used, three cells can be placed between the wells. Giga-cell modeling capability allows the placement of 40 grid blocks between the wells with a grid block size of 25 m. Obviously, the accuracy of the pressure and saturation solution will be much greater in this case, allowing much more accurate calculation of water and gas breakthrough times. As an example, a 6 million-cell simulation (areal grid size of 82 m with 26 vertical layers) predicted gas breakthrough at a horizontal producing well after 14 years of production. Using the new giga-cell simulation capabilities, a new model was constructed from this model by refining the grid three times in all directions, for areal grid size of 27 m and 78 vertical layers, resulting in a 166 million-cell model, Fig. 4. The 166 million-cell model yielded two additional years of production before the well would reach its GOR limit and have to be shut in.

SAFANIYA AND GHAWAR SIMULATIONS To demonstrate the benefits of the new simulator’s fine gridding capabilities, the operator created a 1.004 billion-cell refined model of the Safaniya offshore oil field from the existing mega-cell model by refining the areal grid size to 15 m and the vertical grid size to 1 ft, Fig. 5. Simulating the reservoir effects of Safaniya’s 50 years of production history by hundreds of wells, run on a cluster of 4,000 Nehalem cores, took only 15 hr. Safaniya was modeled as an oil-water system.

For the Ghawar onshore oil field, a three-phase (gas-oil-water) model of 1.032 billion active cells was generated from the existing 10 million-cell model by refining grid size in the areal direction to 42 m. The reservoir had over 60 yr of production history with thousands of wells, and the run took 33 hr on the same computer cluster used for Safaniya. As one example of the benefits derived from giga-cell simulation in these reservoirs, Fig. 6 compares the predicted water and oil saturations for an area of Ghawar under a given production scenario using a mega-cell (left) and a giga-cell (right) model. The red coloring represents oil, and the blue represents water.

The mega-cell simulator shows that water will move much faster, sweeping a larger area, leaving no oil behind. The giga-cell simulation, however, shows remaining oil pockets behind the front. These oil pockets were hidden in the mega-cell model by the numerical dispersion effect. The trapped oil indicated by the giga-cell simulation could be produced by sidetracking the wells. Therefore, in this example, giga-cell simulation presented an opportunity to recover more hydrocarbons. VISUALIZATION AND INTERACTIVITY Building and analyzing such large models, containing such enormous amounts of data, presents its own challenges, which the company attempted to address in designing its giga-cell simulator.5–9 In addition to using the standard desktop computer mouse, a new approach in visualization using spatial (volume) computing has been introduced. Scientists can use their hands with a specialized detection glove to manipulate data sets on a large wall screen. Using this glove, objects such as a well image can be removed from the wall screen to smaller tabletop screens, manipulated and then returned to the wall screen in their original location within the model. Voice command capability is also useful in building and analyzing these large models—for example, to call up certain data onto the wall screen quickly and easily. Sound is used to aid reservoir engineers in real-time reservoir management. Reservoir engineers in the control center receive large amounts of data online as the simulator runs and history matches the data. Sound or text messages provided by the calibrated model can help translate this data into events taking place in the reservoir that might otherwise be missed by the engineer. For example, messages such as “Water finger approaching Well-X in 30 days” or “Abnormal pressure behavior in the east flank. Suggestion: Reduce injection rate by 20%” can help engineers make informed and timely decisions. NEXT STAGES After demonstrating the potential benefits of giga-cell models on two of the world’s largest oil reservoirs, the next step is to build new giga-cell models from the latest geological models. This is expected to provide significantly improved sweep maps, paving the way to achieve higher recovery targets from the giant fields. Simulator interactivity is being advanced with a goal of a continuously calibrated simulator that can make predictions about the reservoir dynamics, alert engineers and make recommendations on implementation. Ideally, the simulator would be able to issue messages such as “I suggest drilling two new wells in the western flank with GPS coordinates x, y, z to sustain the production targets.” Significantly more data will be available through online measurements and continuous monitoring. Voice recognition technologies are becoming better at understanding spoken commands in various languages. Better graphics technology will be available to render multibillion-cell images in real time. CPU technology will be complemented with graphical processing units (GPUs) to achieve this objective. ACKNOWLEDGMENT The author thanks Saudi Aramco’s management for supporting the development of the POWERS and GigaPOWERS technology. The author also thanks the members of the EXPEC ARC Computational Modeling Technology Team. Contributions by Jorge Pita, Nabil Al-Zamel, Usuf Middya, Larry Fung, Hemanth Kumar, Tareq Al-Shaalan, Tom Dreiman and Abdulaziz Al-Baiz are acknowledged, as well as Heather Bence for organizing and editing the text of this article. LITERATURE CITED 1 Dogru, A. H. et al., “A parallel reservoir simulator for large-scale reservoir simulation,” SPE Reservoir Evaluation & Engineering, 5, No. 1, February 2002, pp. 11–23.

|

- What's new in production (February 2024)

- U.S. operators reduce activity as crude prices plunge (February 2024)

- U.S. producing gas wells increase despite low prices (February 2024)

- U.S. oil and natural gas production hits record highs (February 2024)

- Dallas Fed: E&P activity essentially unchanged; optimism wanes as uncertainty jumps (January 2024)

- Enhancing preparedness: The critical role of well control system surveys (December 2023)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)