Part 3 of 3: Many drilling hazards can be mitigated or avoided using casing or liner drilling, managed pressure drilling or solid expandable liner technologies.

David Pritchard, Successful Energy Practices International; Patrick L. York, Scott Beattie and Don Hannegan, Weatherford

Managing drilling hazards requires understanding how the incorporation of mitigating practices and technologies into the well design can improve the risk profile and add value. To achieve this understanding, risk assessment must be applied to the mitigating practices and technologies under consideration. From a drilling hazard management (DHM) perspective, adding value means improving both the risk profile and the cost-benefit balance of the overall operation from a risk-adjusted perspective. Any new mitigant must decrease the likelihood of the risk event occurring, and the risk-adjusted cost should be financially beneficial to the overall operation. It is therefore important to understand how technologies can improve the ability to mitigate and manage risk and can improve the ultimate value of a well.

APPLYING FIT-FOR-PROBLEM TECHNOLOGY

The many and varied technologies available to assist in drilling complex wells are often underutilized. In light of the workloads imposed on today’s drilling engineers and well supervisors, it has been easy to apply familiar tools that have generally worked in previous well situations rather than investigate and apply the most fit-for-problem technology. Conversely, applying technology for technology’s sake is seldom the best approach; often, implementing good drilling practices may be the best solution to the current challenge.

As highlighted in the two previous installments of this article series, the most prudent approach involves two steps: first, identify well objectives that are specific, measurable, achievable, relevant and timely, or SMART; second, develop a thorough understanding of the uncertainties and risk mitigants.

Studies conducted over the past decade have shown that about 50% of drilling hazards resulting in nonproductive time (NPT) can be either avoided or mitigated using good drilling practices such as “well listening.”1 Most of the other half of drilling hazards can be mitigated or avoided through the use of drilling with casing (DWC)/drilling with liner (DWL), managed pressure drilling (MPD) or solid expandable technologies. These technologies are only a few of many in the drilling professional’s tool box, and none should be considered a panacea.

Because multiple resources exist that detail the workings of these technologies,2–4 this article provides only a brief review of how they work, then focuses on how DWC/DWL, MPD or solid expandable systems can be applied to a real example to substantially reduce well risk and cost in a set of complex wells within a very complex reservoir.

Drilling with casing/liner. DWC or DWL can be deployed to reduce risk in many hole sections or casing sizes and is a relatively simple, safe and inexpensive insurance when drilling through trouble zones.

With DWC, the casing string is used as the drillstring instead of drill pipe. Since the 1950s, it has been common in some areas of the world to drill in the final tubing string and cement in place with the drill bit still attached. Modern DWC started in the early 1990s and differs from previous applications in that it is not limited to the final string. To date, this technology has been used in about 2,000 applications. With the exception of a few experimental wells, casing has been used to drill specific sections of the wellbore rather than the entire hole.

Reducing drilling flat time. A key benefit of DWC is time reduction. The time associated with tripping pipe and running casing, including much of the circulation time involved, is removed. Connection time savings alone are about 12%, assuming 3.5 min. for 90-ft drill pipe and 5 min. for 40-ft casing with an on-bottom rate of penetration (ROP) of 50 m/hr. At 100-m/hr ROP, the savings increase to 18%.5

DWC also eliminates other NPT involved in operations such as reaming, circulating high-viscosity pills and conductor cleanout runs. Other potential savings result from the reduced incidence of unscheduled events like hole collapse when using DWC. Typical total time savings from DWC range from 30% to 50% of the time from section spud to leakoff test, Fig. 1.

|

|

Fig. 1. An example illustrating flat time reduction due to DWC.

|

|

Getting casing to bottom. DWC eliminates the tripping of drillstrings and conventional casing-running operations, as well as the resultant deterioration of time-dependent formations. The fact that the casing is always on bottom ensures that where the drillable casing bit reaches is where it can be cased.

Eliminating problems related to tripping. Tripping the drillstring may result in many other problems such as surge-and-swab effect, lost circulation, key-seating, borehole stability problems and well control incidents. Elimination of pipe tripping prevents the occurrence of these problems.

Drilling depleted zone and overcoming lost circulation. Lost circulation is a frequent occurrence in mature fields and areas with weak formations. It is a contributing factor to another serious problem that plagues drillers: stuck pipe.3

It might appear that DWC would increase this risk because the casing could get stuck before reaching the planned casing point. One would also expect lost circulation to be a potential problem with DWC because the smaller annular clearance between the casing and borehole wall increases the frictional pressure losses, thus increasing the ECD. In fact, the results indicate that DWC significantly reduces lost circulation. The exact mechanism that provides this benefit is subject to debate, but there is strong evidence that it results from the smearing of drilled cuttings and mud solids into the borehole wall, creating a plastering effect that mechanically builds an impermeable filter cake.6

Many case histories, published papers and documented results demonstrate the reduction of lost circulation and enhanced well control, and—with no recorded stuck pipe incidents—there is a compelling argument for DWC. But whether DWC should be the first choice for drilling trouble zones is another question.

Enhancing borehole quality. The inherent stiffness of the casing string in the wellbore produces a less tortuous hole, providing a smoother wellbore and reducing the risk of key-seating and mechanical sticking. The stiff assembly is also less prone to vibrations, reducing the mechanical impact damage on the borehole wall. Drillstring vibrations have been attributed to borehole stability problems and oval-shaped holes.

Improving safety. Some potentially hazardous operations may be eliminated when using DWC. Drilling surface hole in shallow waters with high currents can require deployment of divers. Divers are not required when using DWC, as the string does not have to be pulled out of the hole. Another advantage is the elimination of hammering operations. Loading and rigging up pile hammers is often considered to be one of the most hazardous operations carried out on the rig floor.

Reducing rental costs. DWC eliminates the need for conventional bottomhole assembly (BHA) components, and can eliminate the need for one or more strings of drill pipe.

Improving hydraulics. The annulus between the BHA/casing OD and borehole ID is reduced in DWC; thus, under the same operating conditions, DWC delivers higher annular velocity than conventional drilling. The improvement ranges 81–134%, averaging 110%. As a rule of thumb, the DWC annular velocity is roughly double the conventional annular velocity.

Managed pressure drilling. MPD is an advanced form of primary well control usually employing a closed and pressurizable circulating mud system, which facilitates drilling with precise management of the wellbore pressure profile.

The primary objective of MPD is to optimize drilling processes by decreasing NPT and mitigating drilling hazards, and to enable drilling of otherwise technically or economically un-drillable high-complexity prospects.

MPD’s specialized equipment and techniques have evolved since the mid-1960s on thousands of US land drilling programs and are considered status quo by many who pioneered the root concepts. Compared to conventional rotary drilling with jointed pipe and weighted mud, MPD applications have established a commendable well control incident track record.7

Because MPD addresses NPT, the technology is of greatest potential benefit to offshore drilling programs where cost of lost drilling time is much higher than onshore. Although MPD has been safely and efficiently practiced from all types of offshore rigs and produced the desired results in the process, it is still considered a relatively new technology in the offshore.

Nevertheless, since MPD technology and enabling tools were introduced to offshore drilling decision makers in 2003, there have been hundreds of applications globally in marine environments, from both fixed and floating rigs.

Drilling-related issues such as excessive mud cost, slow ROP, wellbore ballooning/breathing, kick-detection limitations, difficulty in avoiding gross overbalance conditions, differentially stuck pipe, risk of twist-off and resulting well control issues contribute to defining the offshore industry’s need for MPD technology. Kick-loss scenarios that frequently occur when drilling into narrow or relatively unknown downhole pressure environments also define a requirement to deviate from conventional methods. Excessive drilling flat time and HSE issues further indicate the necessity for a technology that addresses the root causes.

Each of the four variations of MPD is applicable to specific drilling-related challenges or hazards. On some complex wells, combinations of the variations may be required to better address trouble zones from spud to TD. Each variation has deepwater potential and unique application to complex drilling programs, and enabling equipment is commercially available to accommodate all types of offshore rigs.

Constant bottomhole pressure is applicable to narrow or relatively unknown drilling windows, HPHT wells, pressure fluctuation-induced wellbore instability, ballooning/breathing and well control scenarios.

Pressurized mud-cap drilling is applicable to severe loss circulation and/or drilling into sour formations.

Dual-gradient drilling, with or without a marine riser, is applicable to depleted formations and to avoid gross overbalance associated with a tall column of annulus returns in deepwater riser systems. Hydraulically speaking, dual gradient tricks the well into thinking the rig is closer than it is—by removing some of the mud and cuttings weight, creating two or more pressure-versus-density gradients via injection of light liquids, subsea pumps, downhole pumps or combinations thereof in the annulus returns path.

Returns flow control is simply drilling with a closed-annulus returns system immediately under the rig floor for HSE purposes only.

Solid expandables. Solid expandable systems were initially developed to reduce drilling costs, increase production of tubing-constrained wells, and enable operators to access reservoirs that could otherwise not be reached economically.

Although the first related patent was issued in 1865, it wasn’t until the mid-1900s that operators in the Soviet Union successfully expanded corrugated pipe with pressure (hydro-forming) and roller cones to patch openhole trouble zones. This transitional system and its relevant application further motivated the evolution of expandable technology.

The nature of the wellbore itself dictates what expansion tools and systems are applicable, whether in open or cased hole. Today, expandable technology is used to construct deeper, slimmer and higher-production wells and to repair or seal worn and damaged pipe.

In downhole applications, solid expandable technology reduces or eliminates the telescopic profile of the wellbore, Fig. 2. In open hole, the technology extends casing intervals in preparation for drilling through trouble zones or when an unplanned event in the wellbore requires sacrificing or compromising a casing point as designed in the drilling plan.

|

|

Fig. 2. Wellbore slimming through the use of solid expandable openhole systems.

|

|

In an openhole environment, the most common application runs a solid expansion system, expands it and ties it back to the previous casing string. This structural approach facilitates the extension of the previous string of conventional casing while minimizing the slimming of the well profile during well construction.

The type and size of system used in a project depends on the conditions that demand mitigation. Unexpected problems may require the application of a one-off installation, which is especially common in exploratory wells. Offset data can identify formation characteristics that may warrant planning in the system as a design contingency. Typical drilling problems that can be mitigated with an expandable liner solution include:

• Inadequate hole stability

• Overexposed hole as a result of drilling issues, equipment failures, prolonged tripping, etc.

• Overpressured formations

• Underpressured formations

• Close fracture-gradient/pore-pressure tolerances

• Poor isolation across multiple zones

• Remediation for casing that was inadvertently set shallow.

In contrast to a last-resort application, expandable systems may be used as a fundamental casing string as an integral part of the well’s basis of design. This proactive approach enables the system to be installed over the trouble zone or above the zone to facilitate the installation of a conventional casing string over the trouble zone. With either scenario, the basis of design is maintained. Whether an expandable system is used as part of the plan or for contingency purposes, the technology saves hole size, compensates for unplanned events, and allows for flexibility in well planning.

MITIGATING COMPLEX WELL CHALLENGES

The following real-well example illustrates the effective planning and application of the technologies discussed above. This well was one of a set of wells to be drilled through very complex formations near the foothills of a mountain range.

Defined goals for the well included the following:

• Maintain less than 2° inclination at casing point (about 2,000 ft).

• Drill Section 1 formations to about 6,600 ft MD. Build angle from 2,000 ft (kickoff point) to 22° inclination.

• Drill Sections 3 and 4 to the top of pressure ramp to about 13,000 ft MD. Directionally drill tangent section from 7,000 ft to about 11,400 ft, and then continue drop section with dogleg severity of 1°/100 ft, keeping direction to the east.

• Run LWD tools to obtain accurate geological data.

• Stay vertical (less than 3° inclination) and maintain azimuth to reach the target according to the drilling plan.

• Drill, core, log and isolate Target 1 high pressure and consider isolation contingencies.

• Drill, core, log and isolate Target 2 depleted formation and consider contingencies for high differential pressures and stress.

• Drill and complete both targets with non-damaging fluids.

As discussed in the first installment of this article series, these well goals do not meet the standard of SMART well objectives.

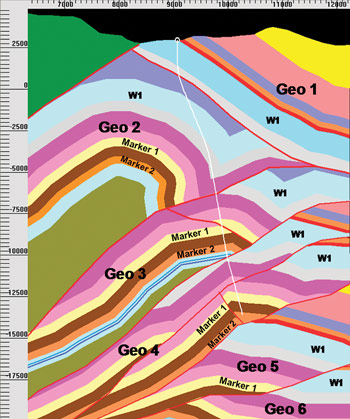

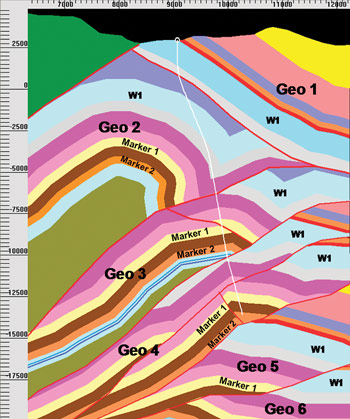

The seismic and offset well information indicated complex geology; depth uncertainty due to seismic resolution; trajectory passing up, down and cross-dip; and uncertainty in the types of hydrocarbon present. The geological complexity was such that the same formations were encountered several times by the prospective wellbore due to severe faults and geophysical events that occurred during and subsequent to their deposition, Fig. 3.

|

|

Fig. 3. Geological map of the example well.

|

|

Purpose of technical limit analysis. The initial well required about 360 days to drill. After implementing good drilling practices and without applying technology mitigants, this time was reduced to 216 days. However, the subsequent technical limit analysis highlighted additional opportunities to further reduce the drilling time. The purpose for the technical review of the wells to be drilled was to understand:

• What depth hazards existed and what created them

• How well design would impact hazard risk management

• The geotechnical environment

• Practices and technologies that could mitigate the hazard

• Performance measurements to be utilized

• The framework for choosing the correct mitigation(s)

• Future recommendations for alternative solutions.

After reviewing the offset data, including 260 detailed daily drilling reports from the offset well, performance objectives were analyzed to determine:

• The average time on the analog well

• Where the NPT had been expended

• How much time could be saved with improved practices and technologies

• What the hazards were and why they occurred

• A baseline for technical-limit time iterations (i.e., to sustain learning).

Risk/consequence profiles of all hazards had to be developed; these would provide a baseline to derive a risk-assessed cost-benefit analysis of the hazard mitigants.

Technical-limit engineering using both good drilling practices and a variety of cutting-edge technologies indicated that drilling time to TD could be reduced by almost half, from 216 days to 115 days, Fig. 4.

|

|

Fig. 4. Comparison of conventional and technical-limit drilling curves.

|

|

Reducing risk and improving drill time. The following summarizes the opportunities that exist to improve the well economics through the applications of the DWL, MPD (pressurized mudcap) and solid expandable technologies.

Drilling the top hole section with casing ensures verticality and stability, and uses a rock strength that is well within the range of cutter technology. It removes three days’ drilling time and enables the ability to extend the shoe depth. In addition, using DWC in this application improves leakoff tolerance for the next hole section and simplifies the drilling margins.

Using DWL as a “hole cleaning while drilling” method, after conventionally drilling the last two hole sections for the drilling liners, ensures that these liners successfully reach their total depths. Additionally, this application facilitates well stability under MPD conditions while minimizing running and cementing risks, lost time, NPT and flat time.

Using pressurized mudcap drilling from the top of the hole down eliminates the risk of up to 33 days’ lost time; the risk-adjusted cost-benefit balance is at least a 11 times better than using conventional drilling alone in the top hole section. Applying this MPD method also eliminates the risk of losing over 13,500 bbl of expensive oil-based mud in the top hole. Additional benefits include better control of confining stresses while accepting losses; elimination of the need for turbine drilling with impregnated bits, especially where temperature is not an issue; and the ability to use cheap, expendable water-based mud—because losses become non-consequential, cuttings cure loss zones and the cap controls cavings. Figure 5 indicates the areas of the well where the DWC/DWL and pressurized mudcap were applied to the trouble zones.

|

|

Fig. 5. Drilling curves with DWC/DWL and pressurized mudcap drilling technologies applied in the upper hole sections.

|

|

The application of openhole expandable liner in either 7⅝-in. x 9⅝-in. size (resulting in a post-expanded ID of about 7½ in.) or a 8½-in. monobore size (resulting in a post-expanded ID of 8⅝ in.) allows a liner to be installed below the 9⅝-in. conventional casing string. This expandable solution allows for mitigating the trouble zone while enabling the running of a 7-in. (or smaller) string of conventional casing, adding an extra casing string without loss of hole size. However, within the 8½-in. hole section (which requires under-reaming the hole section over the trouble zone by 1 in. if the expandable liner is to be installed) the formation is extremely hard. This was evidenced by highly worn impregnated bits; stabilizers out of gauge; difficult conventional reaming and torquing; drillstring stalling (not turbine); highly worn turbine bearings; a high percentage of sandstone in cuttings; and the fact that overbalance was greatest when pore pressure was at its lowest values.

To effectively evaluate the uncertainties of using each technology being considered, a comprehensive risk analysis must be preformed including the technology and its particular application within the well. Table 1 presents the risk analysis conducted on the example well for liner drilling and mud-cap drilling (to mitigate risk of fluid loss) and the use of expandable drilling liner (to mitigate risk of stuck pipe).

| TABLE 1. Risk analysis conducted on the example well for liner drilling, mud-cap drilling and expandable drilling liner |

|

CONCLUSION

The key to mitigating and managing risk lies in understanding the importance of a stage-gated planning process, developing SMART objectives, and acknowledging and defining possible uncertainties and risk applied to practices and technologies. Successful drilling hazard management depends on a cognizant and deliberate recognition of the project’s risks. If executed effectively, the process yields a comprehensive awareness that provides a foundation to not only mitigate and manage risk but optimize operations. Risk assessment should be conducted for any operation, and the process implemented should be used to critically challenge each facet of the well design.

To this end, it is important to understand how practices and technologies can improve both risk management and the ultimate value of the well.

LITERATURE CITED

1 York, P. et al., “Eliminating non-productive time associated with drilling trouble zones,” OTC 20220 presented at the Offshore Technology Conference, Houston, May 4–7, 2009.

2 Al-Umran, M. et al., “New 5½ in. solid expandable systems provide effective technology for successful workover project in Saudi Arabia,” SPE 08057 presented at the SPE Saudi Arabia Section Technical Symposium, Alkhobar, Saudi Arabia, May 10–12, 2008.

3 Jianhua, L. et al., “Use of liner drilling technology as a solution to hole instability and loss intervals: A case study offshore Indonesia,” SPE/IADC 118806 presented at the SPE/IADC Drilling Conference and Exhibition, Amsterdam, March 17–19, 2009.

4 Nas, S. et al., “Offshore managed pressure drilling experiences in Asia Pacific,” SPE/IADC 119875 presented at the SPE/IADC Drilling Conference and Exhibition, Amsterdam, March 17–19, 2009.

5 Scott, R. et al., “Pushing the limit of drilling with casing,” OTC 16568 presented at the Offshore Technology Conference, Houston, May 3–6, 2004.

6 Watts, R. D. et al., “Particle size distribution improves casing-while-drilling wellbore strengthening results,” SPE 128913 presented at the 2010 IADC/SPE Drilling Conference and Exhibition, New Orleans, Feb. 2–4, 2010. 7 Jablonowski, C. J. et al., “The impact of rotating control devices on the incidence of blowouts: A case study for onshore Texas, USA,” SPE133019-MS presented at the 2010 Trinidad and Tobago Energy Resources Conference, Port of Spain, Trinidad, June 27–30, 2010.

|

THE AUTHORS

|

| David Pritchard is a petroleum engineer with 40 years of experience, including management of worldwide drilling and production operations. He has consulted for an array of independents, major companies and service providers. As owner of Pritchard Engineering and Operating, Mr. Pritchard developed, participated in and operated a number of oil and gas properties in the ArkLaTex region of the US. He holds a BS degree in petroleum engineering from the University of Tulsa. |

|

| Pat York is the Director of Commercialization and Marketing for Weatherford Intl.’s Solid Expandables and Drilling Hazard Mitigation product/service lines. He has 38 years of oil and gas industry experience. Before joining Weatherford, Mr. York earned a BS degree in electrical engineering at Northwestern State University in 1972 and pursued his MBA degree there before launching his oilfield career. |

|

| Scott Beattie has 22 years of oilfield service experience. After spells with Halliburton and Baker Oil Tools, he has spent the past 14 years with Weatherford Intl. in various roles, primarily supporting drilling technologies. Mr. Beattie’s latest assignment is in Kuala Lumpur, Malaysia, as Global Business Unit Manager for Drilling with Casing. He is a key member of Weatherford Intl.’s Drill Hazard Mitigation team. |

|

| Don Hannegan is the Drilling Hazard Mitigation Technology Development Manager for Weatherford Intl. He received World Oil’s 2004 Innovative Thinker Award for his role in conceiving and developing specialized equipment and concepts applicable to managed pressure drilling of challenging and complex wells. He was recently appointed by the University of Texas Petroleum Engineering Extension Service (PETEX) to serve as lead author of a textbook to be titled Drilling Hazard Mitigation Tools & Technology. |

|