Placing a gravel pack through existing completion tubing helped put a shut-in well back onstream after four years.

Mohd Razeif Roslan, M. Nazar M. Deris and M. Hafiz Mohamad, Petronas Carigali; Shahryar Saebi, Mohd Nur Afendy and Ivan Munoz, Schlumberger

Sand production is a major challenge for the upstream oil and gas industry, often leading to loss of production, sand disposal issues, the need for routine cleanouts, damage to well jewelry and stuck well accessories. Sand control methods usually yield the most effective results when they are implemented early in the life of a well, before sand production leads to potentially irreversible problems, such as excess water production or formation subsidence. Workover with conventional gravel packing is one way to alleviate the problem in wells that start sand production at a late stage; however, this can be a costly undertaking, and is often not economically justifiable. In 2009, a through-tubing gravel pack (TTGP) technique was used to revive sanded wells in an oil field offshore the sultanate of Terengganu, a state of Malaysia—the first application of the technique in the country. This technique may provide a more economical solution than conventional gravel-pack workover for sanding in mature wells.

BACKGROUND

The candidate field has been in production since 1982. The reservoir consists of several layers, including the unconsolidated (J-sand) layer. Similar to most of the early fields developed in the Malay Basin, all the wells in the field were completed without any sand control measures. Sand production was not expected under the normal planned drawdown; however, as the field has aged, and with a higher drawdown profile, sand production has significantly increased.

Well A, for which the initial producing intervals were isolated, was recompleted in the J-sand layer by March 2005 and started producing at 250 bpd. Unfortunately, the well only produced for three months before it was shut in due to severe sand production. Despite several coiled tubing (CT) interventions to perform sand cleanout, it was not possible to flow the well for a single day, and the well was shut in for four years.

Examination of the drawdown profile of the unconsolidated J-sand layer was conducted to obtain a better understanding of the reservoir. The compressional travel time of the J-sand, based on available sonic log data, was 110 µs/ft—within the critical region for sanding to occur. In addition, based on the simulated drawdown profile, the critical drawdown pressure for the J-sand layer was 150 psi. With the current flowing profile and reservoir pressure depletion, the simulated drawdown was more than 520 psi, making it likely that the wellbore sand matrix would fail. Available reserves were marginal, and the cost of mobilizing a workover rig to perform a conventional gravel-pack completion was considered uneconomic, so Petronas considered a variety of lower cost, rigless, remedial sand control methods appropriate for mature fields.

In situ sand consolidation. Artificial tackifying materials (substances that are, or can be activated to become, sticky to the touch) have been available for many years. One of the earliest such material to be used was phenolic resin. Several other materials and processes have subsequently been developed, including other types of resin, coking, solder glass, nickel plating and aluminum plating. While resins are generally the least expensive of these in situ sand control techniques, all of the consolidation methods are currently relatively expensive. The key to success of any in situ process relies on effective placement of the chemical throughout the zone. Adequate post-treatment permeability must be maintained throughout the treated interval to achieve the desired productivity level. An adaptation of this technique is a gravel-pack treatment in which the carrier fluid contains fluoboric acid, which has the capability to react with clays and strengthen the formation bonding.

Resin-coated gravel pack without a screen. This unique application of the frac-packing prestressing technique incorporates an advanced in situ technology in which artificial particles, such as resieved gravel, are precoated with a resin and injected into the formation around the wellbore. After a polymerization process has created a hardened network around the wellbore, excess material in the casing is drilled out. This exposes the perforations (now filled with a permeable consolidated material) and allows fluid flow into the wellbore while holding back solids. To be successful, this method requires that all perforations be properly filled with resin-coated gravel.

Through-tubing sand screen. In the through-tubing sand screen technique, a designated screen is deployed through the existing tubing. The sandface completion, consisting of several joints, crossovers and the screen itself, is hung at the end of the tubing across, or above, the perforated interval. However, this method is not widely used because of the risk of jetting effects from the perforated production interval and the possibility of creating hot spots. In addition, sand buildup can cover the screen assembly once the well’s rat hole is filled.

Through-tubing gravel packing. TTGP completions control formation sand flow by placing a downhole sand filter across the perforated intervals. This filter is formed when the gravel-pack sand filters out the formation sand and the screen filters out the gravel-pack sand. Ideally, this allows production fluids to pass through with minimal restriction. Several new technological advances in gravel pack fluid systems, perforation techniques, downhole equipment and services have been developed to improve rates of success and reduce the cost of TTGP completions, which are deployed using CT.1

Selecting the optimum rigless sand control technique. A review of the available choices for a rigless sand control operation in Well A indicated that neither the in situ sand consolidation technique nor resin-coated gravel pack without screen were viable solutions due to the length of the producing interval, doubts about treatment placement efficiency and concerns about the post-treatment retained permeability of the near wellbore area. Installing standalone sand screens was not considered a reliable and long-lasting solution because of the possibility of loss of production due to sand buildup in the perforation tunnels and annular space around the screens, and also because of the risk of creating hot spots on the screens—i.e., eroded regions from high inflow.

After consideration of the reservoir properties and the expected challenges associated with each of the rigless sand-control options, it was concluded that the most suitable solution for the candidate well was gravel packing. Particle size distribution (PSD) analysis of a sample taken from the well showed that the completed J-sand exhibited an extremely nonuniform profile with a uniformity coefficient of 13.5 and fine sand with a mean size of 160 µm, Fig. 1. The gravel pack would be able to handle such properties, not only to screen out the sand from being produced, but also to provide support in retaining the near-wellbore formation.

|

|

Fig. 1. Well A formation sand particle size distribution.

|

|

The TTGP method was chosen as the preferred option to provide a low-cost, simple and effective method for recompletion of the candidate well. A number of potential TTGP methods were available. Having reviewed the options, it was decided to recomplete the candidate well using a method that employs a vent screen and isolation packer. This method ensures the best possible perforation packing efficiency and annulus pack quality, resulting in low completion skin and sand-free production.

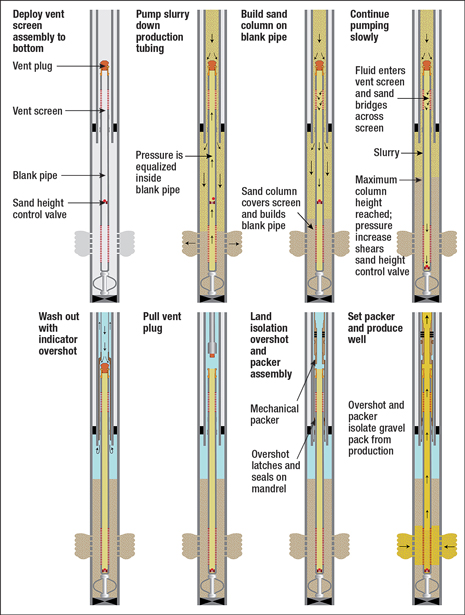

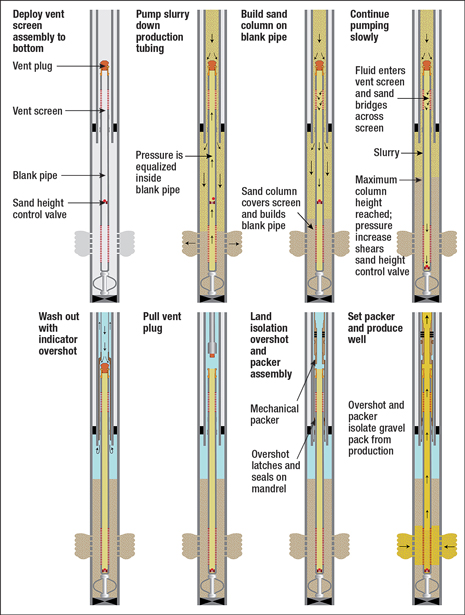

The vent screen method has been used for many years in conditions requiring remedial sand control. This technique uses two screen assemblies separated by blank pipes that are placed and packed in the casing. Production will only enter the lower screens.2 The vent screen assembly consists of a bull plug, premium screens, bow spring centralizers, a sand height-control valve, blank pipes, a polished nipple and a vent screen.

The vent screen and isolation packer TTGP method allows high pumping rates down the production string. It secures the gravel-pack annulus by a mechanical packer and overshot. The method incorporates a sand-height control valve that provides a) better pack quality and height in the annulus by preventing fluid leakoff through the vent screen while the sand column builds on blank pipe; b) positive indication of achieving screenout; and c) an annular pressure control on the sand pack for better grain-to-grain contact.

Unlike other methods, the vent screen and isolation packer technique allows fracturing or high-rate water pack. It also provides better perforation pack efficiency and overall productivity, and ensures building a stable and compacted pack around the screens and blank pipes. A disadvantage of the method is that it requires multiple trips to install.

THE PROJECT

For the first step of the offshore Malaysia project, simulations were performed to ensure that the expected post-completion production results would justify the costs of the TTGP operation. The success of sand control treatments in cased holes, measured in terms of well productivity and treatment life, is greatly affected by shot diameter, density and perforation damage. Perforation tunnels must be open so that they can be filled with high-permeability gravel to prevent filling with low-permeability formation sand. If perforations are plugged, gravel cannot be deposited in the tunnels as carrier fluid flows into the formation. The greater the perforation density, the smaller is the drawdown through each perforation tunnel and the lower the velocity through each effective perforation. In effectively gravel-packed wells, the lower velocity resulting from high perforation density and large-diameter perforations reduces screen erosion and increases the life of the sand control treatment. The magnitude of the pressure drop through higher-density, large-diameter perforations is also reduced, resulting in higher wellhead pressure and greater oil or gas production.1

Simulations indicated that adding perforations and increasing the communication path between the reservoir and the wellbore would deliver a production gain, Fig. 2. The existing interval was reperforated to increase the perforation density from six to 12 shots per foot (spf) and, in addition, a new interval was perforated to maximize the length of the producing interval.

|

|

Fig. 2. Predicted production rate after TTGP.

|

|

Based on the PSD analysis, 20/40 mesh resieved sand was selected as the appropriate gravel size and type for the application. The gravel pack slurry was prepared using 3% KCl brine. The base fluid was then loaded with 1-lb-per-gallon-added (ppa) gravel to increase placement efficiency and prevent formation of bridges in the annulus that could result in premature screenout. In performing the TTGP completion, the wellbore cleanout, stimulation and installation of the completion equipment were provided via a coiled-tubing unit. Well control is important during such an operation, and the wellbore must be kept full of kill fluids throughout.

The project plan included the stages of operations shown in Fig. 3.

|

|

Fig. 3. TTGP completion method using vent screen and isolation packer.

|

|

Execution challenges. Workover operations in old wells can incur several risks, and the actual operation can take longer than planned due to unexpected circumstances. After the sand cleanout operation using CT was completed in the candidate well, a severe leak was detected in the tubing close to the planned setting depth for the isolation packer. Several attempts were made to seal the leakage by installing a tubing packoff. The tubing packoff did not stop communication between the annulus and tubing; therefore, the decision was made to connect two pumps—one to the tubing and one to the annulus, and pump at the same time to ensure no flow of proppant to the annulus during the gravel-pack operation, while maintaining the treatment pressure below the maximum allowable casing pressure.

Another complication that occurred during the operation was a continuous influx of sand into the wellbore from the weak, unconsolidated sandstone formation. After each CT sand cleanout operation, the CT was run back into the hole to check total depth, but the sand height was never the same as the previous cleanout depth. Multiple cleanout trips were made to solve this issue, but eventually the sand control assembly was set higher than the planned depth because part of the wellbore was filled up by formation sand.

The sand control assembly, consisting of 300-µm premium (sintered laminate mesh media) screens, sand-height control valve, blank pipes and vent screen assembly, was prepared and run using CT. The running assembly—consisting of CT connector, dual-flapper check valve, sealed-tubing swivel, handling pup joint, hydraulic disconnect, removable vent plug and hydraulic release tool—was prepared to run and set the sandface completion. The assembly was deployed with a fluid column as a barrier.

The assembly was set in position, and the CT was retrieved. The gravel-pack operation was performed through the production tubing with no indication of a screenout. The gravel-pack treatment had to be repeated five times to achieve the final screenout because of the large void space behind the casing. At the last two stages of pumping operations, the gravel concentration was increased from 1 ppa to 2 ppa and the pumping rate was reduced to induce a screenout. After the screenout was confirmed by restressing the pack, the slickline was run and the vent plug was retrieved. The isolation packer and production overshot were then run and set to isolate the annulus from the tubing in order to avoid fluidization and producing of the pack around the screen and to prevent losing the sand control barrier.

Results and lessons learned. After nine months of production, the well was producing about 180 bpd. The sand-retention performance after the TTGP completion has been exemplary. A number of lessons were learned from this application, including the following:

Sand cleanout can be performed using viscous pills. Nitrogen can be considered in case assistance is required to lift the debris and sand. A dummy run should be made to ensure that the gravel pack assembly can be run to total depth safely, and tubing and production packer integrity must be checked prior to mobilizing for a TTGP operation.

Tubing packoff can be used to repair tubing leakage; however, for this case, it did not repair the leak. Retrieval of tubing packoff might also be an issue and, for this operation, it had to be fished using a CT unit instead of wireline. The dual-injection method (performing gravel-pack treatment from tubing and maintaining pressure in the annulus) was successfully used to overcome a tubing leakage problem.

The gravel-pack operation may have to be repeated several times to fill up the void spaces behind the casing because of the history of sand production in the target interval. Sufficient amounts of gravel and fluid must be available on site to avoid operational delays. A suitable chemical treatment should be used to contain sand flow prior to setting screens to prevent repetitive sand cleanout operations.

Studies should be performed to assess whether productivity can be increased by reperforation and stimulation prior to performing gravel-pack operations. Two packers can be used to isolate tubing leakage. The first packer is set on top of the vent screen followed by spacer pipe covering the leakage point, and the second packer is installed above the spacer pipe.

Well control is critical and, for this case, deployment was performed with a fluid column as a barrier and storage tanks available to top up the well. The gravel-pack assembly should be run with no delay after the final check trip if there is a possibility of more sand influx from the reservoir to the wellbore. Screenout should be induced by reducing the pump rate and increasing proppant concentration if necessary. A frac-pack, rather than conventional gravel pack, option can be considered if the well is a suitable candidate for fracturing.

CONCLUSIONS

The first TTGP operation in Malaysia was completed successfully. This cost-effective and reliable method of sand control is particularly attractive for wells with sanding problems and marginal reserves in which rig-based remedial operations are not economically feasible. This TTGP operation should be considered for reviving idle wells or increasing the production of wells that are producing at restricted production rates due to sanding problems. Other operators in Malaysia are now considering this solution for addressing sanding problems in old wells.

ACKNOWLEDGMENTS

This article is based on IPTC 13974, presented at the International Petroleum Technology Conference, held in Doha, Qatar, Dec. 7–9, 2009.

LITERATURE CITED

1 Lee, C. C. et al., “Effective thru-tubing gravel-pack methods in Attaka Field,” SPE 72132 presented at the SPE Asia Pacific Improved Oil Recovery Conference, Kuala Lumpur, Malaysia, Oct. 8–9, 2001.

2 Bell, Jr., T. A. et al., “Achieving high-rate completions with innovative through-tubing sand control,” SPE 76904 presented at the SPE European Formation Damage Conference, The Hague, May 21–22, 2001.

|

THE AUTHORS

|

| |

Mohd Razeif Roslan is a Production Technologist for Petronas based in Kuala Lumpur. He holds a BEng degree in chemical engineering from the University of Sheffield, UK.

|

| |

M. Nazar M. Deris is a Senior Well Completion Engineer for Petronas, based in Kuala Lumpur. He holds a BEng in petroleum engineering from the Technological University of Malaysia.

|

| |

M. Hafiz Mohamad received a BEng degree in petroleum engineering from the Technological University of Malaysia. He works for PCPP Joint Operating Co.—a JV of Petronas, Malaysia, Pertaminia and Petro-Vietnam— as a Senior Production Technologist.

|

| |

Shahryar Saebi is a Senior Sand Management Services Engineer with Schlumberger based in Kuala Lumpur.

|

| |

Mohd Nur Afendy is a CT Technical Engineer with Schlumberger based in Kemaman, Malaysia. He holds a BEng degree in mechanical engineering from the Science University of Malaysia.

|

| |

Ivan Munoz is Schlumberger’s Sand Management Services/Completions Global Account Manager for Petronas. He holds a bachelor’s degree in mechanical engineering from the University of Zulla, Venezuela.

|

|