In the late 1960s, steamflooding boosted output sevenfold at California’s Kern River Field. Today, reservoir surveillance, 3D reservoir modeling and horizontal drilling are extending the heavy oil field’s economic life for years to come.

James F. Swartz, Charles Piestch and Stephen D. Cassidy, Chevron North America E&P Company

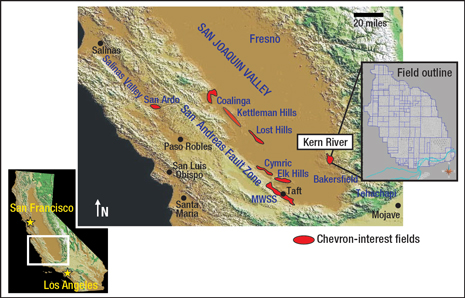

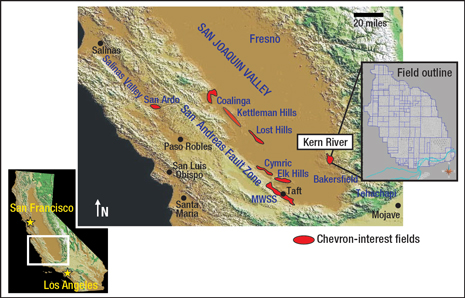

Discovered in 1899 and estimated to hold over 3.5 billion bbl of original oil in place, Kern River Field was a sleeping giant until the late 1960s, when steamflooding began and production ramped up from 19,000 bopd to over 142,000 bopd by the mid-1980s. For most of the period between 1980 and 2000, steamflooding sustained daily oil production over 120,000 bpd. Located in the San Joaquin Valley about 90 mi northeast of Los Angeles, California, it is one of the largest heavy oil fields in the US, Fig. 1. Now in decline, it still produces about 78,000 bopd currently. The field produced its 2 billionth bbl of heavy oil in 2007. To date, more than 20,000 wells have been drilled.

|

|

Fig. 1. The Kern River heavy oil field is located in the southern San Joaquin Valley near Bakersfield, California.

|

|

Since the 1990s, continued innovations have enabled further improvement in reservoir recovery, reducing production decline rates and extending the life of the field. These innovations include geostatistical 3D earth modeling, to make the most of the large volume of well information at the field, and, more recently, the application of horizontal wells for late-life oil recovery. In addition, a project is under way to reduce the reservoir pressure from the underlying aquifer in order to allow more effective heating and production from some areas of the lower zones that were previously bypassed during development.

RESERVOIR CHARACTER

The reservoir consists of amalgamated braided stream channels with the top of the reservoir encountered 100 ft to 1,000 ft below the surface. Porosities range 29–33% and permeabilities lie between 1 D and 8 D. Nine producing zones are recognized in the stratigraphic column, with additional stratigraphic complexity introduced by the variable continuity of the braided stream depositional setting. The formation outcrops updip to the east of the field.

Nearly all production from Kern River Field is heavy oil, produced from unconsolidated quartzo-feldspathic fluvial sands of the Upper Miocene Kern River Formation. The productive interval is about 800 ft thick with an average net-to-gross ratio of 76%. The oil has average gravity of 13°API and average viscosity of 4,000 cP at initial reservoir temperature.

The structure of the field is a homocline on the east flank of the San Joaquin Basin overlying the east–west-trending Bakersfield Arch. General structural dip is about 4° to the southwest. The top oil surface corresponds with the potentiometric surface, indicating that the oil migrated until reaching the level of zero hydrostatic pressure, where it remained until discovery. Oil is encountered as shallow as 50 ft below the surface in some places.

HISTORY OF INNOVATION AND TECHNOLOGY

With nearly 50 years of steamflood history, Kern River Field has served as a natural laboratory for the development and refinement of completion and reservoir management technologies for steamfloods. Following the successful use of bottomhole heaters and a short period of hot water injection (less successful due to severe channeling), steam utilization testing was initiated in 1962. This breakthrough in recovery technology initially took the form of cyclic steaming of producing wells. Starting in the late 1960s, full steamflood development was implemented in the field (Fig. 2), with dedicated injectors drilled in the center of groups of four or eight producers that are typically drilled in a square pattern covering 2.5 acres.

|

|

Fig. 2. The dramatic impact of steamflooding technology at Kern River Field resulted in increasing production for over 20 years after it was first implemented.

|

|

Due to the long history of steamflood operations in Kern River Field, there is abundant performance data on steamflood response—both production information and reservoir surveillance data. The consistent acquisition of reservoir surveillance data has provided a historical look at the evolution of steamflood projects. This information is used for performance prediction in new steamflood developments in Kern River Field and other analogous reservoirs. Key forecasting parameters of peak oil rate and decline rate can often be reliably predicted for a new steamflood based on the performance of nearby past projects in the field. Chevron’s International Heavy Oil Center research facility is also co-located at Kern River Field, further enabling collaboration and testing of new tools and technologies to enhance recovery for the field and other heavy oil assets around the world.

During the 1990s, Kern River geologists and engineers, with the assistance of logging companies, studied the use of carbon/oxygen (C/O) logs and developed a systematic approach to measure oil saturation and monitor fluid drainage in the Kern River Formation. Dedicated temperature observation wells were drilled on a grid regularly spaced across the field. These wells were used for monitoring the recovery process with temperature surveys, dual-spaced neutron logs and C/O logs. This reservoir monitoring and surveillance process continues today.

Coincident with establishment of the C/O logging program in the mid 1990s, 3D geostatistical modeling techniques were developed to visualize the static and dynamic reservoir data. The models became the basis for all drilling and workover programs for the field.

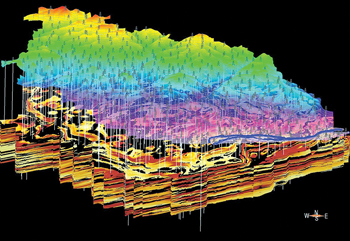

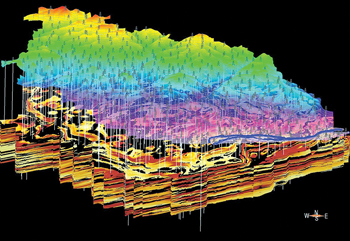

In 2007, a computer-aided full-field 3D reservoir model was built using more than 12,000 resistivity logs for lithologic data and incorporating the most recent saturation information from C/O logs, resulting in a 155 million-cell model resolved into 50 ft x 50 ft x 2 ft cells. The full field model (FFM) is routinely used for evaluation and planning of new development projects, Fig. 3. The 3D models allow for quantification and visualization (2D slices and 3D bodies) of untapped oil-saturated reservoir. Once an area is screened and potential intervals for steamflood recovery identified, the earth scientist selects a subgrid from the FFM for more detailed interpretation, volumetric analysis and opportunity targeting. With the successful application of the FFM, new opportunities have opened up for modeling utilization at Kern River, including streamlining and integrating development projects with fieldwide reserves estimation and business planning. The combination of a disciplined surveillance program combined with earth modeling has resulted in more efficient development of Kern River since the late 1990s.

|

|

Fig. 3. The Kern River 3D earth model showing the sand and shale distribution (shale is black) and variations in oil saturation. The darker red regions represent higher saturation in sands. Surface topography is overlain on top, and the more than 600 observation wells used to monitor temperature and saturation are indicated with vertical lines and derrick symbols.

|

|

A recent application of the surveillance data and the full field model to improve oil recovery is demonstrated in the drilling of horizontal wells into heated areas of the reservoir. Wells are targeted where the oil recovery predicted by decline curve analysis is substantially less than the volumetrically calculated recovery using the FFM. Since 2007, more than 170 horizontal wells have been drilled to improve recovery of the remaining oil, adding more than 12,000 bopd of new production. The wells target zones below 600 ft TVD and typically have laterals of about 1,000 ft Initial production rates from the horizontal producing wells are several times greater than those from offset vertical producers.

Substantial additional development opportunities also exist for application of shallow horizontal drilling and operating technology, which is an area of current technology focus for the development team.

Another recently applied innovation to improve field recovery focuses on development of what was once thought to be unproducible cold oil. The oil is in the downdip portion of the reservoir where aquifer influx maintains a pressure too high to economically inject steam. To enable development, water producing wells have been drilled in the aquifer downdip of the oil to intentionally produce large volumes of aquifer water and lower reservoir pressure. The water from these wells is commingled with produced water from the field and is filtered and exported for beneficial use by the local agriculture water district. Recent steamflood projects have been successfully implemented into the cold oil and have resulted in an addition of 4,000 bopd to the field production. Development of this resource is expected to continue to grow for the next five years or more, Fig. 4.

|

|

Fig. 4. Active development continues at Kern River Field, including two rigs drilling new wells.

|

|

CONCLUSION

Continued innovation and application of technology in steamflooding, reservoir surveillance and 3D reservoir modeling have enabled Kern River Field to produce more than half of the original oil in place and continue to provide significant production and long-term value to the operator. The performance data gathered over the history of the field, combined with continued reservoir surveillance and testing of new technologies, will enable the field and other heavy oil assets to continue to produce for many more years, maximizing recovery and reaching the full economic potential of the asset.

ACKNOWLEDGMENTS

This article was prepared in part from paper 2009-406 presented at the World Heavy Oil Congress held in Puerto Ordaz, Venezuela, Nov. 3–5, 2009. The authors thank Chevron for allowing presentation of this material. Special thanks to Chevron earth scientists Larry Knauer and Dale Beeson for contributions regarding the integration of reservoir surveillance with earth modeling in Kern River Field.

|

THE AUTHORS

|

| |

Jim Swartz has worked for Chevron for 20 years and currently is the company’s General Manager of Operational Excellence. Previously, he was the Asset Development Manager for Kern River Field. He has worked in various earth science and asset development positions in the Gulf of Mexico and Angola. Prior to entering the petroleum industry with Chevron, he earned a BS degree with distinction in geology from the University of Nebraska and an MS degree in geology from the University of Oklahoma.

|

| |

Charles Pietsch received his BS and MS degrees in petroleum engineering from Texas A&M University in 1985 and 1986, respectively, and an MBA from Duke University in 2002. He is a registered petroleum engineer in Texas. He has worked for Unocal/Chevron for 23 years in various technical and management assignments. His career began in West Texas implementing and monitoring waterflood and infill drilling programs as a reservoir engineer. Mr. Pietsch is the Asset Development Manager for Chevron’s Temblor Thermal Area in California.

|

| |

Stephen Cassidy supervises Chevron’s Applied Reservoir Management Team in Bakersfield, California. He has a bachelor’s degree in physics and electronics from the University of Liverpool and a master’s degree in petroleum engineering from Imperial College, London. Mr. Cassidy has broad international work experience covering drilling, technology management and reservoir management.

|

|