What’s new in production

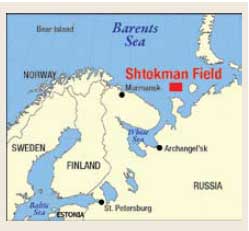

Massive Shtokman steams ahead against economic cross-currents Showing that the global economic downturn need not slow down E&P companies with great ambitions and even greater capital, partners on the massive Shtokman gas field recently announced plans to invest heavily in the development project leading up to a final investment decision by first-quarter 2010. At a budget update on Feb. 10, Gazprom Deputy Chairman Alexander Medvedev said the Barents Sea project is on track and insisted that the downturn will not delay an investment decision. Medvedev added that the partners expect to incur high costs before the FID, an unusual move that he said demonstrates their confidence in the project. Gazprom holds a 51% stake with partners Total (25%) and StatoilHydro (24%). Two days later, another Gazprom spokesman, Andrey Kruglov, announced that the company plans to raise 90 billion rubles ($2.6 billion) in the financial markets this year, primarily “driven by [the] need for funding of our investment program and our long-term strategy.” That investment program, drafted in December 2008 and unchanged in the face of the global economic crisis, calls for 920.44 billion rubles ($24.7 billion). Also on Feb. 12, Total announced plans to spend $200 million by the end of 2009 on feasibility studies for the Shtokman development. According to the Norwegian magazine Tenisk Ukeblad, StatoilHydro is probably spending a similar amount, although company officials have refused to give a number. The total 2008–2009 budget for the consortium, approved in October 2008, is over $800 million. Huge challenges, huge reward. The scope of the project, its remote location and the harsh Arctic conditions create enormous challenges for the consortium, but the potential jackpot is equally large. Situated in the middle of the Russian sector of the Barents Sea shelf, Shtokman Field lies about 370 miles northeast of the Russian seaport of Murmansk, at water depths of 1,050–1,120 ft. With an estimated 134 Tcf of gas and 37 million metric tons (mt) of condensate, Shtokman will be the world’s largest gas project, with capacity to power the US for four years by some estimates. Because of its size, the field is planned for development in three or four phases. During the first, 25-year phase, output of 2.29 Bcfd is expected. About 1 Bcfd of this will be transported by a pipeline to be built from Murmansk to Volkhov to link Shtokman gas to Nord Stream. The rest will be converted to LNG at a 7.5 million-mt/year plant to be constructed by Technip at the village of Teriberka, 62 miles from Murmansk. Pipeline export is expected in 2013 and LNG in 2014. Total first-phase costs are estimated at $15–$20 billion. Subsequent phases will ramp up output to about 7 Bcfd of pipeline gas, 20 million mt/year of LNG and 600,000 mt/year of condensate.

Producing that gas and condensate will require the partnership to overcome some of the harshest winter conditions ever seen in the offshore sector, with typical ice thickness up to 2 m in the cold season. Shtokman is also very iceberg prone, with 220 observed in the past 48 years, and 15 observed in 2003. Two of those recent icebergs weighed more than 4 million tons each, too large to be tugged away. Another challenge is the logistics of stationing a huge production crew in such an isolated environment. Offshore facilities will have to accommodate 200 people, and in summer as many as 350, all of whom must be flown out by helicopter. An additional 120 personnel will be needed at onshore facilities at Teriberka, which has no existing infrastructure to support oil and gas development. Massive construction project. The development plan for Shtokman is one of the industry’s most ambitious ever, including two production topsides totaling over 40,000 tons, a 370-mile, 44-in. trunk line to bring the two-phase flow across an extremely rough seabed topography, the Murmansk–Volkhov pipeline and one of the world’s biggest LNG plants, along with all the necessary infrastructure. Also included will be a massive complex of subsea production systems and risers as well as large subsea compressor drives to move the output to shore. Production facilities will be two ship-shaped floating production units detachable (in case of icebergs) from two huge spars with a unique hourglass design to break approaching ice. A small fleet of iceberg management vessels will also be commissioned. All structural materials will be rated to withstand temperatures of −45°C. Unique opportunity. Paradoxically, the massive amount of construction needed to bring the project online is exactly why this is a good time for the partners to double down on Shtokman while other oil and gas companies are delaying and cancelling projects. Along with the price of oil and gas, the price of steel and other materials has fallen precipitously from the highs of last year, making 2009 a uniquely opportune time to secure contracts for materials and equipment. Indeed, for such a large project, it may make more economic sense to commit to build when both oil and steel prices are low—but both are likely to go up before project completion—than when prices are high. In December 2008, Yuri Komarav, CEO of the Shtokman consortium, told a group of Russian lawmakers that the development will be economically viable at oil prices of $50–$60/bbl. Two months later, the partners have committed to keep the project on schedule, despite the fact that the world hasn’t seen an average oil price above $50/bbl since mid-November 2008. That’s the kind of nerve and forward thinking this industry needs to weather the financial storm ahead.

|

||||||||

- Advancing offshore decarbonization through electrification of FPSOs (March 2024)

- What's new in production (February 2024)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- U.S. operators reduce activity as crude prices plunge (February 2024)

- U.S. producing gas wells increase despite low prices (February 2024)

- U.S. oil and natural gas production hits record highs (February 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)