Stick-slip and lateral vibration become decoupled by replacing stabilizers with roller reamers at drillstring nodes.

Steven F. Sowers and Fred E. Dupriest, ExxonMobil Development Company; Jeffrey R. Bailey and Lei Wang, ExxonMobil Upstream Research Company

Stick-slip and whirl are vibrational problems that limit drilling performance in hard formations and extended reach wells. When these vibrations are present, adding roller reamers to the drillstring can significantly reduce their severity and improve performance.

Whirl is characterized by lateral vibration at the bit and in the BHA. When whirl becomes severe, lateral vibrations cause significant side forces in stabilizers. Frictional drag then causes high torque levels at the stabilizers, which can result in stick-slip (fluctuations in BHA rotational speed). This is referred to as “coupled stick-slip.” When these conditions exist, the replacement of stabilizers with roller reamers reduces torque generation at the contact points. Consequently, more torque becomes available to the bit and the driller may raise WOB. This results in reduced bit whirl and improved ROP. The reduction of bit whirl and elimination of stick-slip prevent damage to bit and BHA components.

Roller reamers also serve the historical purpose of conditioning the borehole. The operator’s field experience indicates that the need for conditioning is often due to whirl-induced borehole features, including spiraling and ledges. Using roller reamers greatly reduces the prevalence and impact of whirl features.

When lateral and torsional vibrations in the BHA become coupled, a torque or torsional vibration limit of the drilling system often prevents the driller from running sufficient WOB to prevent bit whirl. Bit whirl can be detrimental to drilling operations by the development of ledges,1 borehole oscillations,2,3 hole spiraling4 and premature tool failure.5,6 The presence of bit whirl may be detected by analyzing the impact of changes in drilling parameters on Mechanical Specific Energy (MSE).7 MSE measures the amount of energy consumed in drilling a unit volume of rock. Real-time surveillance of MSE across global operations suggests that over 40% of footage is affected by whirl.

When the driller is not constrained by a rig or drillstring limit, parameters may be adjusted to reduce bit whirl. Typically, WOB is increased resulting in an MSE reduction. This indicates that the amount of energy lost to side-cutting and heat generation from whirl vibrations was reduced. In lab conditions, the amplitude of whirl-induced trajectory oscillations, produced when drilling across the interface of two rock samples with a contrast in strength, declined with increasing WOB.3 Field evidence confirms these whirl-induced oscillations in field conditions at the interface of laminated rocks. The operator has noted recent instances where the BHA became mechanically stuck from whirl-induced borehole patterns after drilling a transition between rocks of varying strength.

The use of roller reamers in hard rock drilling environments is common, and drillers have decades of experience with them in mitigating tight hole on connections and trips. While the application is not new, the industry has not always been aware that whirl-induced features were a major cause of the poor borehole behavior. Other practices, like using extended gauge bits or real-time vibration management, have also reduced the feature’s severity. However, even with contemporary practices, roller reamers may still be considered when field experience shows that whirl-induced features remain problematic for tripping. Even minor features may increase friction factors in extended reach wells.

While roller reamers are commonly used for hole conditioning, their use to decouple stick-slip is not widely recognized or implemented. Several papers identify the relationship between the torsional and lateral vibrations at the bit.8,9 A coupled vibrational response model that includes the drillstring, as well as the bit, has been described.10 Decoupling BHA vibrations as a motivator for running a roller reamer in a casing-while-drilling BHA design has been mentioned, but the authors did not discuss the rationale behind it.11

BENEFITS

The vibrational shape in a BHA must be understood to explain how stabilizers contribute to stick-slip. While many models predict critical frequencies, proprietary modeling to predict vibrational tendencies across a continuous range of operating parameters has been developed.5 The proprietary software also determines bending moments and shear forces within the shape. Measured BHA bending moments have been matched by combining the vibrational modes modeled at the actual operating parameters under conditions that did not align with the string’s critical frequency.12

These models show the vibrational shape of a rotating BHA to be sinusoidal. Stabilizers and other contact points with the borehole are modeled in this shape as nodes, and departure of BHA components from the hole’s centerline occurs in the oscillating wave between these nodes. Although the overall appearance is similar to that of a sinusoidal wave, the wave amplitude (displacement from the centerline) varies across the BHA. In previous industry analysis, the shape tends to be dominated by how the BHA responds to a set of operating parameters.

Because the BHA is constrained to zero lateral motion at the nodes (contact points), side forces are concentrated at these locations. The magnitude of these forces increases as the amplitude of the vibrational shape increases. The amplitude depends on BHA configuration, operating parameters and forces imparted by the bit and other downhole tools.

The side force is also not applied uniformly across the stabilizer. The sinusoidal shape in the adjacent member tends to tilt the stabilizers so that point loading occurs at the ends. The result is seen in field operations as rounded shoulders on stabilizer blades. Previously published material discusses optimizing BHA configuration and operating parameters to minimize stress at these nodal points.5,7 This is largely accomplished by moving the contact points within the BHA (e.g., stabilizer placement).

Bit whirl and BHA whirl occur together. As a result, before the BHA reaches a borehole section, the bit cuts a whirl feature into it. This can be inferred when MSE analysis reveals whirl at the bit. For energy to be lost to bit whirl, side cutting must occur. While some energy may be lost to friction between the borehole and drillstring, significant sidecutting must occur to explain the inefficiency often observed in MSE analysis. When side cutting occurs from whirl, some form of a whirl-induced feature is cut into the borehole wall. When the hole is overgauge from bit whirl, the BHA contact points have room to accelerate in their vibrational shape before contacting the borehole wall. In this way, bit whirl amplifies the forces that result from BHA whirl.

Accelerometers on downhole tools often record shock measurements that exceed 50 times gravity acceleration; such accelerations in the BHA can produce very large side forces. Friction from borehole wall contact in the presence of BHA whirl can produce large, variable stabilizer torque values. Such torque prevents the driller from addressing whirl at the bit (increased WOB), because increased WOB increases the severity of torsional vibrations or causes the surface torque to approach drilling equipment’s operating limit. Drilling then continues with severe dysfunction.

BHA whirl cannot be eliminated, and some level of side loading will always exist. Roller reamers change the interaction between the borehole and contact points by introducing a low-friction bearing between the BHA and borehole wall. As such, the torque generated by BHA whirl is greatly reduced.

Roller reamers do not necessarily reduce BHA whirl force, only the resulting torque. However, if the removal of most of the fluctuating torque consumed at the stabilizers allows additional torque (i.e., increased WOB) to be applied, bit whirl may be reduced. Whirl mitigation lessens the severity of whirl-induced patterns, producing a smoother hole that is more in-gauge.

In an in-gauge hole, stabilizers are constrained and do not have much room to accelerate from BHA whirl. Consequently, the side forces that result are lower than those recorded in a borehole enlarged by bit whirl.

High side loads and torque are obviously undesirable, but the decision to introduce roller reamers depends on their operational impact, which is difficult to predict. Consequently, roller reamers are only used when field experience has proven the need. The first application for stick-slip mitigation was by a drill team with a history of chronic downhole tool damage. However, the practice moved to other teams primarily due to the desire to extend ROP limitations.

In the MSE-based ROP management process, bit performance is viewed as being potentially unlimited because increased WOB should always result in increased depth of cut. If increased depth of cut does not occur, it is only because of some dysfunction. In the continuous improvement workflow, ROP is then increased by identifying the dysfunction and redesigning to extend the WOB at which the dysfunction occurs. From a rock-cutting perspective, the dominant vibrational dysfunction is whirl, which is mitigated by raising WOB. However, WOB cannot be raised if it drives the string into stick-slip. By decoupling BHA whirl and stabilizer torque, it becomes possible to introduce more bit torque without initiating stick-slip. These are complex relationships. MSE surveillance allows trained personnel to observe effects in real time and quantify improvements.

A significant portion of borehole quality improvement can be explained by the indirect effect that roller reamers have in enabling operations personnel to run drilling parameters that reduce or eliminate bit whirl. However, it is clear that roller reamers also serve the traditional role. Since roller reamers are often run full gauge and have a cutting structure, they may smooth certain whirl-induced borehole features.

For example, if an instantaneous dogleg is generated as a result of whirl, as the roller reamer moves over the dogleg, the cutting structure will remove some of the rock from it and reduce its severity. Whirl can also produce spiraling surface patterns in the borehole.3 When such patterns exist, the cutting structure in a roller reamer helps smooth the pattern’s ridges. Even when bit whirl patterns cannot be completely prevented by optimizing operational practices along with bit and BHA design, roller reamers help to lessen the impact of these patterns.

LIMITATIONS

While experience with premium, sealed-bearing roller reamers in the last five years has been very positive, it is worth noting that tool life at operating conditions is not unlimited. However, the tools have been used in demanding applications with a very low failure rate. Roller reamers’ life is highly dependent on the downhole operating conditions encountered. Similar to other sealed-bearing tools, like roller-cone bits and under-reamers, their life is largely a function of bearing seal life, which is highly dependent on vibrations and the heat that results. To minimize loading, the dynamic vibrations model is used to position the reamer to minimize lateral and bending loads. Even when run in optimal conditions, run times in some wells may exceed the bearing assembly’s life. Tool performance may also vary between designs. The introduction of roller reamers into a given field environment should include a plan to collect data that allows wear rate and contributing factors to be characterized.

When conditions are not appropriate for roller reamer use or if they are unavailable (e.g., due to remote logistics), certain lubricants have helped decouple whirl from stick-slip. Although the benefit obtained with lubricants is not as significant as that observed with roller reamers, lubricants can provide decoupling benefits similar to those obtained with roller reamers in both vertical and extended reach drilling. In general, this use of lubricants is limited, because the benefit of roller reamers is more significant and the cost to run and maintain a lubricant in the drilling fluid is quite high.

EXTENDED REACH WELLS

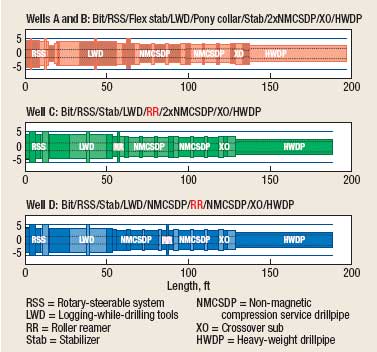

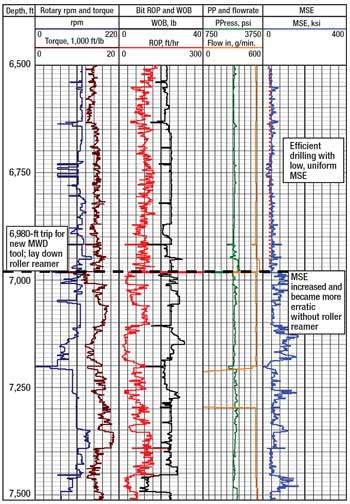

The first case study compares four extended-reach wells drilled in one field. Figure 1 shows the BHAs used in the 12¼-in. section of these wells for comparison. Wells A and B used identical BHAs without roller reamers while Wells C and D used a roller reamer to replace the top stabilizer. Post-analysis determined that the BHAs used in Wells A and B had less propensity toward lateral vibrations than those used in Wells C and D. Furthermore, the BHA used in Well D had less propensity toward lateral vibration than that used in Well C. As a result, the roller reamer BHAs should have recorded higher lateral vibrations than the other wells; this was confirmed by downhole measurements. This was helpful in assessing a roller reamer’s ability to mitigate whirl-induced stick-slip.

|

|

Fig. 1. A roller reamer replaced the top stabilizer in the BHAs for Wells C and D.

|

|

Although Wells A and B recorded lower lateral vibrations than Wells C and D, the lateral vibrations appear to have initiated stick-slip, Fig. 2. When the top stabilizer was replaced with a roller reamer in Wells C and D, the stick-slip measurement became low and uniform regardless of the level of lateral vibration. Further, in Wells A and B, higher levels of lateral vibration correspond to increased levels of stick-slip, Fig. 3. This observed coupled response with a stabilizer as the top contact point and a lack of a coupled response with a roller reamer aligns well with the previous conceptual discussion of BHA vibrations coupling at contact points.

|

|

Fig. 2. While the BHAs in Wells A and B produced somewhat lower lateral vibrations, the roller reamer BHAs in Wells C and D yielded lower levels of stick-slip.

|

|

|

|

Fig. 3. In Wells A and B, stick-slip levels increase as lateral vibrations increased (a coupled response). In Wells C and D, the roller reamer BHAs showed no coupled response.

|

|

As the roller reamer BHAs allowed increased torque to be transferred to the bit, WOB was increased. The resulting wellbores were smoother and required less energy to drill, Fig. 4. One can see the MSE declined significantly, since less energy was used to drill the section using roller reamers. Furthermore, on Well D, the roller reamer BHA produced a smoother hole with a noticeably lower friction factor than the BHA used to drill the remainder of the 121⁄4-in. section.

|

|

Fig. 4. Removal of coupled stick-slip with roller reamers allowed more WOB, reducing whirl in Wells C and D.

|

|

VERTICAL CONGLOMERATE INTERVAL

The operator drilled several wells that encountered a hard conglomerate interval in a vertical 8¾-in. hole section in a recent program. Several trips were typically required to drill through the interval. Four wells used roller reamers in the conglomerate. While whirl-induced borehole features often caused tripping problems in offsets, there were no problems noted in the footage drilled with roller reamer BHAs. This aligned well with other roller reamer experiences. Roller reamers helped to decouple whirl and stick-slip vibrations, allowing more WOB. This is believed to have reduced the level of bit whirl and the amplitude of whirl-induced patterns. The reamers may have also removed some of the remaining whirl-induced borehole patterns.

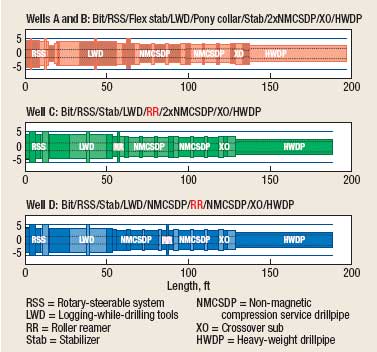

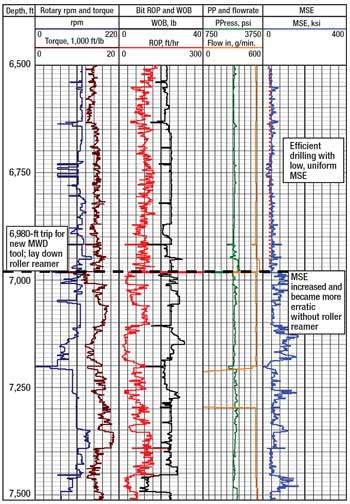

Figure 5 shows the effect the roller reamer had on drilling efficiency in the conglomerate section. Prior to tripping at 6,980 ft to replace a failed MWD tool, drilling was efficient; this can be seen in the low, smooth MSE curve. A roller reamer was used in place of the top stabilizer in this BHA. During the trip, the roller reamer was replaced with a stabilizer, since its bearings were slightly loose and there was no backup on location. The bit and BHA configuration were not changed, and the dimensions of the stabilizer were similar to those of the roller reamer. Drilling progress without the roller reamer was slow, and surface vibrations became severe as torsional vibrations were generated by coupled lateral vibrations. Within several hundred feet, drilling operations were halted to repair damage to the top drive caused by these vibrations.

|

|

Fig. 5. After laying down the roller reamer, MSE became erratic as lateral and torsional vibrations were recoupled.

|

|

CONCLUSIONS

The torque generated in solid-body stabilizers from whirl-created lateral loads may be sufficient to initiate stick-slip in a given situation. When used to replace conventional stabilizers at contact points with high lateral loading, roller reamers eliminate most of the capacity for torque generation. This can eliminate drillstring torsional vibrations and stick-slip.

Roller reamers can improve borehole quality in a couple of ways. When performance is limited by the torque capacity of a drillstring or drilling rig, or by the torsional stiffness of the drillstring, the replacement of stabilizers with roller reamers will greatly reduce torque fluctuations generated at BHA contact points by whirl. This allows the driller to mitigate bit whirl by applying higher WOB and to reduce the severity of whirl-induced borehole features. Last, if whirl-induced features cannot be prevented by optimizing drilling parameters along with bit and BHA design, the cutting structure of the roller reamer will remove some of the borehole features that result from drilling with bit whirl.

ACKNOWLEDGEMENTS

The authors thank ExxonMobil Development Company and ExxonMobil Upstream Research Company for their support. They also thank the individuals that contributed, including: Sam Vera, Roman Churilov, Shane Harris, Morten Grini, Erika Biediger and others. Special thanks to Alan Shive for collecting and organizing much of the data. This article was adapted from SPE/IADC 119375, which was presented at the SPE/IADC Drilling Conference and Exhibition held in Amsterdam, Netherlands, March 17–19, 2009.

LITERATURE CITED

1 Brett, J. F., Warren, T. M. and S. M. Behr, “Bit whirl: A new theory of PDC bit failure,” SPE Drilling Engineering, 5, No. 4, December 1990, pp. 275–281.

2 Pastusek, P. and V. Brackin, “A model for borehole oscillations,” SPE 84448 presented at the SPE Annual Technical Conference and Exhibition, Denver, Colorado, Oct. 5–8, 2003.

3 Boualleg, R., Sellami, H., Menand S. and C. Simon, “Effect of formations anisotropy on directional tendencies of drilling systems,” IADC/SPE 98865 presented at the IADC/SPE Drilling Conference, Miami, Florida, Feb. 21–23, 2006.

4 Gaynor, T. M., Chen, D. C. K., Stuart, D. and B. Comeaux, “Tortuosity versus micro-tortuosity: Why little things mean a lot,” SPE/IADC 67818 presented at the SPE/IADC Drilling Conference, Amsterdam, Netherlands, Feb. 27–March 1, 2001.

5 Bailey, J. R. et al., “Drilling vibrations modeling and field validation,” IADC/SPE 112650 presented at the IADC/SPE Drilling Conference, Orlando, Florida, March 4–6, 2008.

6 Mitchell, R. F. and M. B. Allen, “Case studies of BHA vibration failure,” SPE 16675 presented at the SPE Annual Technical Conference and Exhibition, Dallas, Texas, Sept. 27–30, 1987.

7 Dupriest, F. E., Witt, J. W. and S. M. Remmert, “Maximizing ROP with real time analysis of digital data and MSE,” IPTC 10706 presented at the International Petroleum Technology Conference, Doha, Qatar, Nov. 21–23, 2005.

8 Richard, T. et al., “Influence of bit-rock interaction on stick-slip vibrations of PDC bits,” SPE 77616 presented at SPE Annual Technical Conference and Exhibition, San Antonio, Texas, Sept. 29–Oct. 2, 2002.

9 Barton, S., Lockley, R., Stroud, D. and S. Peach, “Coupling of downhole dynamics recorder enhances system-matched approach to drill bit design and application with a specific rotary steerable system,” SPE 102182 presented at the SPE Annual Technical Conference and Exhibition, San Antonio, Texas, Sept. 24–27, 2008.

10 Christoforou, A. P. and A. S. Yigit, “Active control of stick-slip vibrations: The role of fully coupled dynamics,” SPE 69093 presented at the SPE Middle East Oil Show, Bahrain, March 17–20, 2001.

11 Bourassa, K. et al., “A case history of casing directional drilling in the Norwegian sector of the North Sea,” IADC/SPE 112560 presented at the IADC/SPE Drilling Conference, Orlando, Florida, March 4–6, 2008.

12 Neubert, M., Heisig, G., Forstner, I. and F. Mounzer, “Verification of an advanced analysis model with downhole bending moment measurements,” SPE 93864 presented at the Asia Pacific Oil and Gas Conference and Exhibition, Jakarta, Indonesia, April 5–7, 2005.

|

THE AUTHORS

|

|

Steven F. Sowers earned a BS in petroleum engineering from Texas A&M University in 2005. He worked in field engineering and technical studies assignments prior to joining the global Technical Operations Support Group in 2008. Sowers presently coordinates global implementation activities for ExxonMobil’s Fast Drill Process, as well as providing engineering support in the redesign of practices to extend performance limiters.

|

|

| |

Fred E. Dupriest earned a BS degree in mechanical engineering from Texas A&M University. He joined ExxonMobil in 1977 and has worked in a variety of operational assignments. He led the development of ExxonMobil’s Fracture Closure Stress practices to mitigate lost returns, as well as the Fast Drill performance management process. Dupriest is presently a Technical Advisor to the global drilling organization in critical well planning, trouble response and performance management.

|

|

| |

Jeffrey R. Bailey earned a BS degree in physics from Stanford University, and MS and PhD degrees in mechanical engineering from the Massachusetts Institute of Technology. He developed BHA vibration models and microseismic fracture mapping tools while working for ExxonMobil in drilling and subsurface technology for nearly 20 years. Bailey is an Engineering Associate at the ExxonMobil Upstream Research Company in Houston.

|

|

| |

Lei Wang earned a BS degree in electrical engineering from Nanjing University of Aeronautics and Astronautics and an MS degree in aerospace engineering and a PhD degree in mechanical engineering from North Carolina State University. He has two years’ experience in vibration modeling for bottomhole assemblies, specializing in drilling data analysis, signal processing, data mining and pattern recognition. Wang is an Engineering Specialist for ExxonMobil Upstream Research Company in Houston.

|

|

| |

|