Renewed interest in heavy oils and rock asphalt in South Central Kentucky

Direct-current and microwave heating, along with traditional steamflooding and SAGD, are being considered to meet these reservoirs’ great challenge: economically lowering the viscosity of heavy-end hydrocarbons.

Direct-current and microwave heating, along with traditional steamflooding and SAGD, are being considered to meet these reservoirs’ great challenge: economically lowering the viscosity of heavy-end hydrocarbons.Michael T. May and Kenneth W. Kuehn, Western Kentucky University, Bowling Green, Kentucky Heavy oils and rock asphalt occurring in Mississippian and Pennsylvanian strata along the southern and southeastern edges of the Eastern Interior (Illinois) Basin in Kentucky are of increasing interest to companies seeking long-term commitments to the region, Fig. 1. Although development of asphalt rock at or near surface has occurred for well over 100 years, there is renewed interested in the heavy to borderline heavy oil located in primarily Mississippian-aged formations. These are estimated to contain 3 billion bbl of oil minimally, but some estimates suggest up to 6 billion bbl of oil reserves—sufficient to attract a significant number of North American companies to the region. This is especially true considering the advent of more environmentally friendly and efficient recovery technologies such as heating the reservoir using Direct Current (DC) or microwave energy, which are believed to be effective within a few hundred feet below surface. This article briefly discusses the occurrence of these hydrocarbons, defines basic terminology for heavy oil and tar sands focusing on common physical and chemical properties, reviews a series of projects and discusses past and proposed recovery methods in the area, along with opportunities and challenges for fully developing this important hydrocarbon-rich region.

OVERVIEW Unconventional resources in the form of heavy oil- and bitumen-impregnated sandstones in South Central Kentucky create a reserve in the billions of barrels of oil equivalent. It is important to recognize the overall context of these resources in terms of estimates of world reserves and how they are defined. We define heavy oil as oil with an API gravity less than 22.3°. Based on a 2007 BP review, there is 1,208 billion boe of proved reserves worldwide.1 The same review suggests that heavy oil in place is five to 10 times greater than proved reserves, or about 6,000–12,000 billion boe. Tar sands technically are considered unconsolidated sands saturated with oil or tar and commonly contain clay and other impurities. However, some agencies or states (e.g., Kentucky Geological Survey) also refer to lithified sediments that possess tar as tar sands. In Canada, tar sands are referred to as oil sands. The tar sand resource in the US is estimated at 60–80 billion boe.2 US tar sands tend to be hydrocarbon wet, while Canadian oil sands are typically water wet. Much of the US resource will therefore require different recovery techniques. In South Central Kentucky, mostly in Edmonson and Grayson Counties (Fig. 2), Geologist Martin Noger suggested in 1984 that there is over 3 billion boe of proved reserves, about 5% of the US total.3 Based on work by consultants over the last few years, it is highly probable that this area actually contains 10% of the US total.

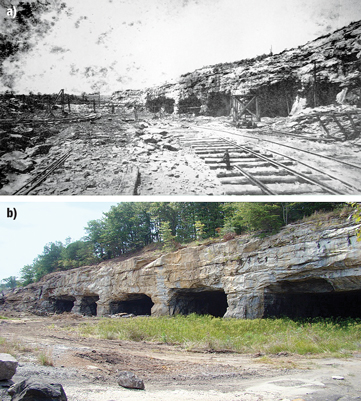

In South Central Kentucky, the unconventional resource occurring as asphalt rock has been recovered by surface quarrying and via underground workings such as room and pillar mining for over 100 years, Fig. 3. The heyday for extraction of such heavy-end hydrocarbons was in the first half of the 20th century. In the past 5 years, two of these quarries have been reopened to provide raw materials for the paving industry. The focus of this article, however, is on the wider interest in heavy oil and oil located in the deeper parts of the basin. These areas may be candidates for secondary or tertiary recovery methods more typical of conventional oil resources. It is believed that many of the heavier oils can be made more mobile by decreasing their viscosities through heating the reservoirs.

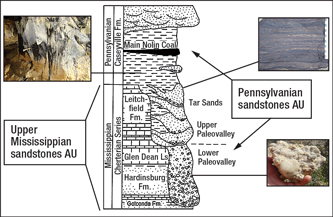

HISTORICAL CONTEXT The geology of the Brownsville Paleovalley and Kyrock Asphalt areas in Edmonson County (Fig. 2) has been recognized as extraordinary within the entire Eastern Interior (Illinois) Basin for many years.4–6 This is due to the quality of exposed Mississippian (Chesterian) siliciclastic and carbonate lithologies and basal Pennsylvanian (Morrowan) siliciclastics. Heavy oil and asphalt resources are most important economically in the area near the outcrop belt of basinal Pennsylvanian (e.g., Brownsville Paleovalley) and Chester rocks. Asphalt or “tar sands” created boom towns such as Asphalt, Black Gold, Sweeden and Kyrock as well as a trade name for road paving material—Kentucky Rock (Kyrock for short). Kyrock material was marketed heavily by the Kentucky Rock Asphalt Company in the early 1900s and was used for paving many well-known places including Chicago, the Indianapolis 500 Motor Speedway, Rio de Janeiro, Brazil, and Havana, Cuba. Kyrock was bought by W. G. Reynolds in 1958. Also in the late 1950s, paving with asphalt was discontinued with the advent of heated “ready mix” applications. After a 50-year hiatus, there is presently a renewed interest in both heavy oils and asphalt centered in Edmonson County, Ky. OCCURRENCE OF HYDROCARBONS Heavy oils and eventually standard-viscosity oils are located just inward from the outcrop belt containing asphalt rock. These hydrocarbons were sourced from within the Eastern Interior Basin and upon maturation migrated updip and were emplaced on the basin’s edge, mostly in sandstones. Strata of interest include the Mississippian-aged Chester Series sandstones and basal Pennsylvanian sandstones, pebbly sandstones and conglomerate. The prospective Chester sandstones include the Big Clifty sandstone of the Golconda Formation, the Hardinsburg sandstone and the Tar Springs sandstone of the Leitchfield Formation. The basal Pennsylvanian is represented by the Caseyville sandstone, which unconformably overlies Chester strata, Fig. 4. The Caseyville has stratigraphic synonyms associated with sandstones or conglomerate quarried for asphalt rock, aggregate or high-silica refractory material, particularly in Edmonson County, such as the Kyrock sandstone and Bee Spring sandstone. These Pennsylvanian strata have been the only materials quarried since about 2005 for use as a portion of the regional asphalt mix.

The US Geological Survey in 2009 defined strata of the Illinois Basin that are prospective in the context of petroleum systems possessing defined reservoirs and source rocks. This petroleum system nomenclature is illustrated with the generalized stratigraphic column shown in Fig. 4. Coupled with its summary investigation of regional stratigraphy and petroleum systems of the Illinois Basin, the USGS conducted an assessment of basin’s undiscovered oil and gas resources.7 This work defined 19 Assessment Units (AUs) and four petroleum systems in the Illinois Basin. Two of the AUs roughly correspond to those discussed in this paper, the Pennsylvanian sandstones AU and the Upper Mississippian sandstones AU, but these AUs are defined for technically recoverable (conventional) resources. This article is focused on the Upper Mississippian and Pennsylvanian, but within stratigraphic units possessing unconventional resources in addition to those recognized by the USGS as technically recoverable. Hydrocarbon source rocks. The most probable source rock for the Upper Mississippian and Pennsylvanian sandstones petroleum systems in South Central Kentucky and western Kentucky is the shale within the Devonian-Mississippian New Albany Shale and its stratigraphic equivalents, such as the Chattanooga Shale.8 Although some source rocks for conventional oil and gas are associated with Pennsylvanian strata, these shales and coals are stratigraphically above the Lower Pennsylvanian Caseyville sandstone and equivalent strata and Upper Mississippian Chester sandstones. Physical and chemical characteristics. Little systematic work is available publicly regarding the resource’s viscosity, one of the most important metrics for development of the South Central Kentucky area. Based on self-reporting by one group from Canada interested in drilling there, some measured parameters suggest that the Chester sandstones show great promise.9 Based on eight exploratory holes, including some coring, select petrophysical, fluid and stratigraphic properties were reported. The three chosen stratigraphic units of recent exploration are, in ascending order, the Big Clifty sandstone of the Golconda Formation, the Hardinsburg sandstone and the Tar Springs sandstone of the Leitchfield Formation, Fig. 4. The Big Clifty contains sandstone averaging 45 ft in thickness, permeabilities of 100 mD, 15% porosity, oil saturation ranging 40–75%, and 10–30°API gravity. Hardinsburg sandstone reservoirs contain sandstone up to 40 ft in thickness with 40–70% oil saturation, 14% porosity and widely ranging permeabilities (10–400 mD). Tar Springs sandstone has similar maximum sandstone reservoir thickness as the Big Clifty and Hardinsburg, permeability averaging 100 mD, oil saturations measured between 25% and 58%, but higher porosities, averaging 20%. PILOT PROJECTS Table 1 outlines some of the major historical rock asphalt and heavy oil projects in South Central Kentucky. Grayson County provided the region’s first bitumen recovery in 1891. Most asphalt rock for paving was extracted from quarries and mines in Edmonson County from the 1910s through the 1950s, Fig. 3. Reportedly a few extractions were associated with Indy 500 Race Track repairs in the late 1960s. A resurgence of quarrying of asphalt rock for paving material has resulted in not only distribution statewide but also some regional paving (e.g., Talladega Gran Prix Raceway in Alabama).

Interest in recovery of heavy oil and oil located in the deeper part of the basin from outcrops of asphalt rock began as a series of pilot projects primarily in the late 1950s and early 1960s. Many of these were successful, recovering at least half of the petroleum in place. Original recovery methods included steam heat tests and wet forward in situ combustion. These early pilot projects by Gulf Oil, Sunset Petroleum and later tests by Westken Petroleum in the booming early 1980s relied on relatively cheap energy (e.g., coal and natural gas in Kentucky for some of the US’s cheapest electricity) for extraction of the heavier-end hydrocarbons. These early pilot projects also did not have to consider present-day concerns such as the need to offset carbon dioxide emissions by sequestration or use of the CO2 as a gas drive mechanism. Today, thanks to technological advances, this area can be developed more efficiently and within the context of responsible environmental stewardship. DC heating. Heavy oil has been recovered quite successfully in pilot projects that passed direct current electricity between cathodes in producing wells and anodes at conveniently located surface positions or at depth in other wells.10 This nascent technological application, referred to as Electrically Enhanced Oil Production (EEOP), is beginning to show promise, especially by recovering heavy oil at lower costs than by other secondary or tertiary recovery methods. The basic EEOP concept is simple and should be effective in shallow, sulfur-rich reservoirs like those of South Central Kentucky. Electrical current is sent through the reservoir, which in turn heats the target formation through Joule’s heating, thus decreasing the oil viscosity. Experiments using this technology suggest that watercut can be reduced, gas production increased, oil gravity increased, and hydrogen sulfide reduced. Furthermore, DC heating can enhance the pressure gradient toward wells, providing more reservoir drive. Microwave. Another technology uses specific frequencies of microwave radiation to recover oil from various unconventional hydrocarbon resources in addition to depleted oil fields. Much like DC heating, this technology is still in the experimental stage, such as preliminary work conducted by Global Resource Corporation.2 This organization claims to be able to use radio frequency energy associated with a specific microwave frequency to yield a gasification process within a vacuum environment to extract hydrocarbons from the reservoir and crack them into fuels “without environmental issues.” A common frequency of 2.45 GHz is applied, and software-controlled frequencies can be customized for a given target resource. Some believe microwave technology may be more efficient than DC heating,11 and it will be interesting to observe its application in Kentucky. FUTURE STUDIES AND OPPORTUNITIES There are a series of cores housed at the Kentucky Geological Survey’s repository in Lexington, Ky., that were obtained by several companies during assessment of asphalt rock and heavy oil, particularly in the 1980s. Because asphaltenes precipitate in weathered rock or old core, the details of internal stratification and other bedding features are obscured. Future work to discern the details of the reservoir properties and petrophysics such as grain size, sorting, porosity and permeability will require examination of cores with special lighting, such as with a “black light.” Old cores will also need to be calibrated with newly obtained cores to extend the database across a multi-county region. Furthermore, there is a need to obtain values for viscosity for both old and new cores, with a calibration of old cores to new as well as suspended content such as clays in the oil. Existing cores should be slabbed and characterized to present a sedimentological and petrophysical model for the basal Pennsylvanian. Few cores are known to exist (or have been archived or reposed) for the Upper Mississippian, and many of these strata such as the Big Clifty, Hardinsburg and Tar Springs sandstones are being studied in outcrop mainly west or northwest of the asphalt rock areas such as in Butler County. Studies akin to those for establishing sedimentological and petrophysical models for Pennsylvanian cores are commencing for the Mississippian sandstones outcropping in the region. Such work is important because most Steam-Assisted Gravity Drainage (SAGD) recovery methods work best only where there is somewhat homogeneous vertical permeability. Such permeability trends need to be discerned. Comparative studies of heavy oil and oil associated with paleovalley systems may provide better understanding of the distribution of asphalt rock and heavy oil in South Central Kentucky. Near Kyrock in Edmonson County, for example, a series of sub-Pennsylvanian paleovalley wall exposures are in some cases charged with hydrocarbons, and in other places they are devoid of hydrocarbons even at a similar stratigraphic and/or elevation position. In southeastern Kansas and northeastern Oklahoma, it appears that more oil accumulated at the edges of paleovalley systems.12 Some areas of Canada also have tributary valleys that are more prospective than the very large trunk systems.13 Details of the fluvial systems, particularly those of Mississippian age, will have to be studied in more detail. A whole series of basin-wide regional studies demarcating trunk systems and some tributary systems have long established the geometry of basal Pennsylvanian sandstones.14,15 In general it appears that Tar Springs and Big Clifty are parallel to the later axial trends of major Caseyville paleovalleys (such as the Brownsville Paleovalley in Edmonson County, Ky.). The Hardinsburg, in contrast, fans out more relative to the Tar Springs and Big Clifty.16 The isopach patterns for the Mississippian strata will be established in the near future in an initial effort to best understand the most effective recovery of heavy oils. Many of the heavier-end and standard-viscosity oils in South Central Kentucky are sulfur rich, but a refinery about 50 mi away in Somerset, Ky., is being restarted after a recent inoperable period and is to be equipped to process crudes and heavy crudes extracted from the Edmonson County area, the current focus of heavy oil and oil production. This area of Kentucky serves the lower Midwest and the Midwest, solid market areas for petroleum consumption. The proposed development area in South Central and western Kentucky is also strategically located near large military installations, being only 65 mi southwest of Fort Knox and 80 mi northeast of Fort Campbell. The area is also located within easy access to interstate and other important highways with major trucking lines as well as large navigable rivers.

LITERATURE CITED 1 Cited by Schlumberger, “Heavy oil moving forward,” HeavyOilinfo.com website, Oct. 27, 2007, http://www.heavyoilinfo.com/feature_items/heavy-oil-moving-forward. ACKNOWLEDGMENTS Special thanks to the Kentucky Museum at Western Kentucky University for historical images and to the WKU Department of Geography and Geology for its support. The authors also appreciate discussions with John Horne, Fran Hein, Roger Berg and William Florman. The Kentucky Geological Survey permitted publication of select copyrighted figures.

|

|||||||||||||||||||||||||||||||||||||

- Advancing offshore decarbonization through electrification of FPSOs (March 2024)

- What's new in production (February 2024)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- Prices and governmental policies combine to stymie Canadian upstream growth (February 2024)

- U.S. operators reduce activity as crude prices plunge (February 2024)

- U.S. producing gas wells increase despite low prices (February 2024)