Acid diversion using associative polymer technology yields superior results as compared with foam or in situ crosslinked acid.

Benjamin Garcia, PEMEX; Eduardo Soriano, Wendy Chacon and Larry Eoff, Halliburton

Cantarell Field is the most important complex in Mexico and is the second-largest producing field in the world. Matrix acidizing has always been the main stimulation process used to improve production from the carbonate reservoirs that form the main productive zones, and this is especially the case now that this mature complex has reached its production peak.

A critical factor for success of the treatments is distribution of the acid among all productive zones. Since most producing wells are not homogeneous and contain layers of varying permeability, even distribution of the acid is a difficult task. In addition, the water saturation of the various zones has a major effect on the acid distribution. Since acid is an aqueous fluid, it will tend to predominantly enter the zones with the highest water saturation, in many cases resulting in increased water production. This brings with it the multitude of problems associated with high water production.

This article presents the results of approximately 57 high-permeability (1,000-6,000 mD) wells that have been acidized using a novel acid diverter based on Associative Polymer Technology (APT). This polymer inherently reduces the formation permeability to water with little or no effect on the permeability to hydrocarbon. Production log data from several of the treated wells show excellent oil production distribution along the perforated intervals. In contrast, production logs for wells acidized with other diverters, such as foams and in-situ crosslinked acid, showed poorer results.

CANTARELL FIELD

Cantarell Field is located 47 mi northeast of Ciudad del Carmen, Campeche. The main productive zones in Cantarell are highly fractured carbonate formations from the Jurassic, Cretaceous and Lower Paleocene geological ages. Production started in 1979 and reached a peak of 1.1 million bpd in 1981 from 40 oil wells. By 1994 the production was down to 890,000 bpd. One year later the field was producing 1 million bpd due to the addition of new platforms and wells and a nitrogen injection program. This program was capable of injecting 1 Bcfd of nitrogen to maintain reservoir pressure. By 1996 the field was producing 2.1 million bpd.

Acid diversion. In most oil wells, the producing intervals are heterogeneous, containing sections of varying permeability and pressure. Acid treatments tend to predominantly enter the highest-permeability zones, thus bypassing the lower-permeability, or most damaged, layers. In some cases, these high-permeability layers are also predominantly water bearing; thus the acid also mainly enters those zones because of the relative permeability effect. In other cases, the acid may break into a nearby water-bearing zone. In all of these cases, an acid treatment may result in significant increases in water production after the treatment.

Many placement techniques have been used in the past in attempts to achieve uniform placement of acid across all layers. The most reliable method is the use of mechanical isolation devices such as straddle packers that allow injection into individual zones, one by one, until an entire interval has been treated. However, this technique is often not practical, cost-effective or feasible. Without a packer, some type of diverting agent must be used.

Non-mechanical diverting agents that have been used include ball sealers, degradable particulates, viscous fluids and foams. Although each of these has been used successfully, each also has potential drawbacks. In addition, none of these techniques addresses the problem of increased water production that often follows an acid treatment.

For this reason, a material that could inherently decrease the formation permeability to water and also provide diversion is desirable.

Dilute polymer solutions have been shown to decrease the effective permeability to water more than to oil. These types of treatments have been referred to as Relative Permeability Modifiers (RPM), disproportionate permeability modifiers, or simply bullhead treatments. That is, these treatments can be simply bullheaded into the formation without zonal isolation. These systems are thought to perform by adsorption onto the pore walls of the formation flow paths. A large number of such polymer systems have been promoted through the years, and a large volume of literature has been devoted to this topic.1-3

A previous paper described an RPM based on a hydrophobically modified water-soluble polymer (here referred to as APT).4 Because this polymer reduces water permeability with little damage to oil permeability, it was recognized as a potential acid diverter. Another paper has described the laboratory study of this polymer for use as an acid diverter.5

Associative polymers. The solution properties (such as rheology and viscosity) of both ionic and non-ionic, water-soluble polymers are uniquely modified when hydrophobic groups are introduced into the polymer chains.6,7 In addition, the adsorption behavior of hydrophilic water-soluble polymers can also be modified in a unique manner by the introduction of hydrophobic groups. Rather than reaching a plateau adsorption, as is common for hydrophilic polymers, hydrophobic modification appears to produce a continued growth in adsorption with increased polymer concentration. This behavior is attributed to associative adsorption of polymer chains on previously adsorbed layers of polymers.8

The Associative Polymer (AP) used in the current work has previously been shown to exhibit a unique shear thickening phenomenon. However, the solutions used in diversion operations show very low viscosity (< 2 cP) at surface conditions.5 Viscosified or foamed fluids commonly used for acid diversion can result in high friction pressure and require special manifolding and/or pumping equipment. The low viscosity of the AP diverting system results in ease of mixing, low friction pressures, and no special manifolding or pump requirements. The diversion of aqueous fluids occurs only after the material enters the porous media, whether it is naturally fractured carbonate/dolomitic rock or sandstone matrix. It is hypothesized that the increased shear encountered upon entering the rock matrix, coupled with polymer adsorption, results in an apparent “viscosity” increase that may be responsible for the pressure increases usually seen during the treatment.

EXPERIMENTAL PROCEDURES

The experimental procedures for single core flow tests have been published previously.4 Acid diversion tests were run using standard Hassler sleeves. For each test, one core each was taken to residual oil saturation (water core) or residual water saturation (oil core) and initial permeabilities were measured as described in previous papers. The cores were then connected so that the treatment sequence could be bullheaded, allowing the treatment to flow through either core. An ammonium chloride spacer was pumped between the APT treatment and the acid. For the APT treatment and ammonium chloride spacer, a limit of 500 ml or 500-psi differential pressure was used, and in all tests, the 500-psi limit was reached before pumping 500 ml. For the acid stage (5% HCl), the limit was 200 ml or 500 psi, and in each case, 200 ml was pumped without reaching the 500-psi limit. In the final stage, the cores were disconnected and final permeabilities were measured.

RESULTS AND DISCUSSION

Prior work has demonstrated the ability of APT to reduce water permeability with little effect on hydrocarbon permeability.4 Figure 1 illustrates two single core flow tests on sandstone cores. This is for two separate tests, with one core at residual oil saturation and one core at residual water saturation. The core at residual oil saturation showed a 98% reduction in permeability while the core at residual water saturation showed only a 5% reduction in permeability. The RPM effect, rapid pressure increase in core tests and rheological shear thickening phenomenon led to the conclusion that APT might function as an acid diverter. Figure 2 illustrates the typical pressure increase seen when pumping the polymer into a carbonate core. In this test, brine and oil had been cycled through the core, ending with brine. The graph shows the final stage of this brine flow and the treatment stage. Note that the brine flow was at 5 ml/min. while the treatment was run at 1 ml/min. Even with this lower flowrate, when the polymer entered the core, the pressure very rapidly increased from 125 psi to over 490 psi. As will be shown later, this pressure increase is often seen on actual jobs.

|

|

Fig. 1. Single core flow tests on water- and oil-saturated sandstone cores at 175°F.

|

|

|

|

Fig. 2. Pressure buildup during treatment of a carbonate core at 175°F.

|

|

Diversion tests. Figure 3 shows results from a diversion test using two carbonate cores. This test used two carbonate cores cut from the same block, so it is assumed that their permeabilities were similar. One core was taken to residual oil saturation and one core was taken to residual water saturation. A control test was run in which acid was bullheaded into the two cores. As shown in this figure, out of 200 ml of acid, 142 ml entered the water-saturated core and 58 ml entered the oil-saturated core. In the second test, using two new cores, APT was bullheaded into the cores, followed by the acid. In this case, out of 200 ml of acid, 25 ml entered the water-saturated core and 175 ml entered the oil-saturated core.

|

|

Fig. 3. Diversion test with carbonate cores of similar permeabilities.

|

|

In a second set of carbonate diversion tests, cores with a wider permeability contrast were used. In a control test, cores with an initial brine permeability contrast of 5/1 were used. The cores were then taken to residual water and residual oil saturation, with the higher-permeability core taken to residual oil saturation. In this test, 92% of the acid entered the water-saturated core. Similar carbonate cores were used for the diversion test, but the same permeability contrast could not be attained. In this test, the initial brine permeability contrast was 17/1. Again, the cores were taken to residual water and residual oil saturation, with the higher-permeability core taken to residual oil saturation. Following the APT treatment, 69% of the acid entered the water-saturated core. It would be expected that if the control test had been run on cores with a 17/1 permeability contrast, at least 92% of the acid would have entered the water core (based on the 5/1 test results). Thus, it is assumed that the APT did result in diversion of acid into the oil-saturated core. Other laboratories have run similar diversion tests with APT and have seen similar results.9

Cantarell Field results. Large amounts of drilling mud are typically lost to the formation in Cantarell. Several measures have been taken to minimize the damage caused by the lost mud, including the use of low density, foamed and solids-free mud formulations. However, the highly fractured condition of the formations and the depleted scenario of the reservoir still result in massive mud losses. Wells in the Cantarell complex require stimulation to overcome the formation damage caused by this mud loss and also to sustain a commercial level of hydrocarbon production. Bullhead matrix acid stimulation is the main technique used in this field. Acid stimulation through coiled tubing has been used with good results; however, limitations in the size of coiled tubing available in this area leads to long pumping times, making the bullhead technique the main option. The main acid system used is 15% HCl, which is best suited to the bottomhole temperatures, which average around 220°F. The use of a diverting system also has been routine in every stimulation where typical perforated intervals range from 30 to 50 m. The highly fractured nature of these formations and the presence of vugs are also reasons for using a diverting system.

Foam examples. The use of continuous foam was one of the first diversion techniques used in the acid stimulation jobs at Cantarell. Using nitrogen as the gaseous phase, with initial qualities of 50% increasing progressively up to 70%, this continuous foam technique was the recommended one for long intervals with high permeabilities, which are very typical in this field. However, buildup tests and PLTs run after the stimulation treatments often showed skin factor remaining in the formation and heterogeneous production profiles along the perforated interval. In one example, a production profile was run after an acid treatment where foam was used as the diverter. In this example, the bulk of the oil production is coming from the upper 20 m. The buildup test that was run after the stimulation showed a skin factor of 14.

Reservoir data from these wells and some additional ones where PLT logs were not run are shown in Table 1.

| TABLE 1. Reservoir data from acid-stimulated wells |

|

|

In situ crosslinked acid examples. The use of In situ Crosslinked Acid (ICA) as the diverting agent was later initiated because results from the foam applications were not completely satisfactory, according to production logs run immediately after the stimulation treatments. ICA was developed to prevent fluid loss in fracture acidizing and as a diversion system in matrix acid treatments in carbonates. ICA is a gelled acid with a viscosity of about 20 CP that forms a highly viscous, crosslinked gel when the acid in the formation is spent and the pH increases to about 2. This system seemed to show a better distribution of the acid as compared to foam.

A satisfactory production profile was seen along the perforated interval following acid stimulation with ICA. Almost 100% of the perforations are contributing to the oil flow. Well 17 was also acid stimulated with ICA as the diverting agent. Over 90% of the production enters in the first 9 m of the perforated interval. The rest of the oil production apparently is coming from the bottom of the interval. Well 18, shows a contribution of 60% of the total production entering the upper section of the perforations. The rest of the interval does not contribute, with exception of the bottom of the perforations, where 40% of the contribution is observed. Similar observations are seen in the profile of Well 19, where almost 90% of the production enters the middle section of the perforated interval, with 10% in the top. No contribution is seen from the entire lower half of these perforations.

In one example, a well with two perforated intervals was acid stimulated using the ICA diverter. Unfortunately, the bottom interval showed no production following the acid job, perhaps indicating that no acid was diverted to the lower interval. Thus, while some satisfactory results were seen with the ICA diverter, a more efficient diversion system was desired.

APT examples. Other fields offshore Mexico had previously used APT with good results, even in the presence of water and low-permeability formations.10,11 In these cases, diversion away from predominantly water-bearing zones was not the main focus. These results led PEMEX to consider the application of this system in the acid stimulations run in Cantarell Field. This new stimulation campaign using the APT diverter started at the end of 2005 and continued through 2007. Some wells were selected to carry out PLTs subsequent to these stimulations to evaluate the acid distribution in the stimulated intervals. The results observed in the profiles of the PLTs for some of these wells showed very good contribution of the producing interval, which demonstrated good performance by the APT. On the basis of these results, during 2006 almost 50 wells were acid stimulated using APT. While results for all jobs cannot be shown here, the overall conclusion is that APT has provided more consistent diversion than either foam or ICA.

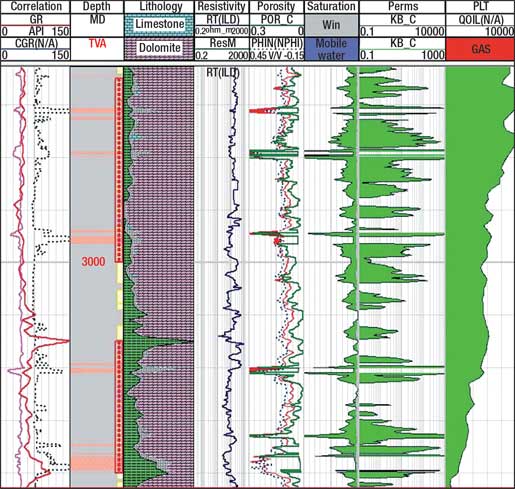

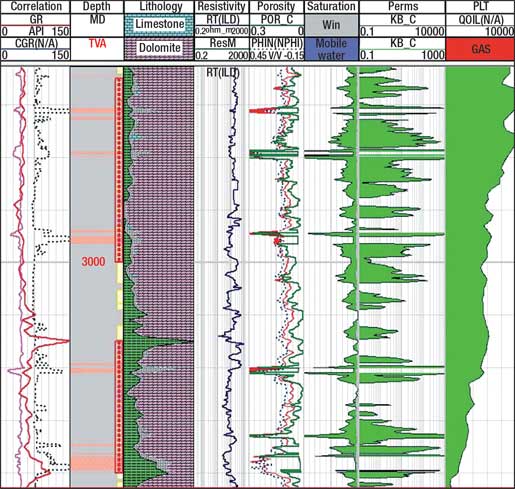

In Well 1, a production contribution of the entire interval slightly loaded to the first half of the perforated interval. The production profile begins at 3,398 m because there was an obstruction in the well below this point. The production profile for Well 2 shows 100% contribution of the entire perforated interval, with major contributions from the bottom. The same situation is observed in Well 3, where the entire interval has contributed to the total production. Also in Well 4, 100% contribution of the entire perforated interval is seen in the production profile shown in the last track. Figure 4 describes a well with two perforated intervals that were acid stimulated. The APT apparently was able to divert the acid throughout both intervals. The PLT shows that both perforated intervals are contributing to the production.

|

|

Fig. 4. Composite log with PLT from a well acid stimulated with APT diverter.

|

|

Pumping charts. Surface pumping pressures measured during the acid treatments have shown that APT provides a larger and more consistent pressure increase than foam or ICA. A particular well was acid stimulated using ICA as the diverter, and a remaining skin factor was left in the formation. Four months later, a second acid treatment was carried out to overcome the damage left from the first treatment as well as to improve productivity, which had decreased in the four months following the first treatment. For this second acid job, APT was used as the diverter. In both cases, 15% HCl was used as the main acid treatment. Figure 5 shows the pressure increase achieved when the APT stage arrives at the perforations. This pressure increase was not observed on the first treatment using ICA. While surface pressure is not a definite indication of acid diversion from a higher- to a lower-permeability zone, it is often the only indicator available.

|

|

Fig. 5. Job chart from a well that was acid stimulated with APT diverter.

|

|

Productivity index. Productivity Index (PI) and oil production data for wells acid stimulated using foam, ICA and APT as the diverter are presented in Fig. 6. This data comes from wells where buildup tests were available. From this information, we can clearly state that the average PI from those wells acid stimulated with APT is higher than from those where foam or ICA was used. The average PI for 22 wells acidized using APT was 351; for 17 wells acidized using ICA it was 219; and for 18 wells acidized using foam it was 178.

|

|

Fig. 6. Productivity index data.

|

|

CONCLUSIONS

Laboratory tests have shown that the APT diverter can divert acid from predominantly water-saturated zones to predominantly oil-saturated zones in both sandstone and carbonate lithology. PLT data from field cases in Cantarell Field show better response from those wells stimulated using APT as the diverter than from those using foam or ICA. Surface pressure response during acid jobs using APT has shown more consistent indication of diversion than during jobs using ICA. PI data shows superior results for wells stimulated using APT as the diverter than using foam or ICA. Results from this field study show that diversion with APT is not limited to wells with high water saturation zones.

ACKNOWLEDGEMENTS

Portions of this article are based on SPE 112413, “Novel acid diversion technique increases production in the Cantarell Field, offshore Mexico,” presented at the SPE International Symposium and Exhibition on Formation Damage Control held in Lafayette, Louisiana, Feb. 13-15, 2008. The authors would like to thank Petroleos Mexicanos and Halliburton management for their support and permission to publish this article. This article is also based on SWPSC 32, “Case histories of a novel acid diversion technique, Cantarell Field, Mexico,” presented at the 55th Annual Southwestern Petroleum Short Course, Lubbock, Texas, April 23-24, 2008.

LITERATURE CITED

1 Zaitoun, A. and N. Kohler, “Improved polyacrylamide treatments for water control in producing wells,” SPE 18501 presented at the International Symposium on Oilfield Chemistry, Houston, Feb. 8-10, 1989.

2 Ranjbar, M., Czolbe, P. and N. Kohler, “Comparative laboratory selection and field testing of polymers for selective control of water production in gas wells,” SPE 28984 presented at the International Symposium on Oilfield Chemistry, San Antonio, Texas, Feb. 14-17, 1995.

3 Kohler, N. and A. Zaitoun, “Polymer treatment for water control in high-temperature production wells,” SPE 21000 presented at the International Symposium on Oilfield Chemistry, Anaheim, California, Feb. 20-22, 1991.

4 Eoff, L. et al, “Development of a hydrophobically modified water-soluble polymer as a selective bullhead system for water production problems,” SPE 80206 presented at the International Symposium on Oil fieldChemistry, Houston, Feb. 5-8, 2003.

5 Eoff, L., Dalrymple, D. and B. R. Reddy, “Development of associative polymer technology for acid diversion in sandstone and carbonate lithology,” SPE Production and Facilities, 20, No. 3, 2005, pp. 250-256.

6 McCormick, C. L., Bock, J. and D. N. Schulz, Encyclopedia of Polymer Science and Engineering, 2nd Ed., 17, 730. Wiley-Interscience, New York, 1989, Vol. 17, pp. 730.

7 Glass, J. E., Ed., Hydrophilic Polymers: Performance with Environmental Acceptance, American Chemical Society, Washington DC, 1996.

8 Volpert, E. et al, “Adsorption of hydrophobically associating polyacrylamides on clay,” Langmuir, 14, 2007, pp. 1870.

9 Al-Taq, A. et al, “Simultaneous acid diversion and water control in carbonate reservoirs: A case history from Saudi Arabia,” SPE 106951 presented at the SPE Europec/EAGE Annual Conference and Exhibition, London, June 11-14, 2007.

10 Reza, G. et al, “A new method for acid stimulation without increasing water production: Case studies from offshore Mexico,” SPE 103711 presented at the International Oil Conference and Exhibition, Cancun, Mexico, Aug. 31-Sept. 2, 2006.

11 Soriano, E. et al, “Relative permeability modifiers and their use in acid stimulation in HPHT low-permeability carbonate formations: Offshore Mexico cases,” SPE 107584 presented at the Latin American and Caribbean Petroleum Conference, Buenos Aires, Argentina, April 15-18, 2007.

|

THE AUTHORS

|

|

|

Benjamin Garcia is a Completion Engineer with 12 years of experience in the oil industry, currently working with PEMEX for offshore operations. Prior to this assignment, he worked for the Mexican Petroleum Institute covering acid stimulation proposals for carbonate reservoirs in southern and offshore Mexico. He has a BS degree in chemical engineering from the National Polytechnic Institute in Mexico.

|

|

|

|

Eduardo Soriano is Technology Leader for Production Enhancement in Halliburton Mexico, responsible for developing engineered solutions and new technology applications to improve productivity. He has 15 years of experience with Halliburton covering well testing, acid stimulation, fracturing and water control. Soriano has a BS degree in petroleum engineering from the National Polytechnic Institute.

|

|

|

|

Wendy Chacon is a Stimulation Technical Engineer for Production Enhancement in Halliburton Mexico; she is in charge of developing technical recommendations on acid stimulation, fracturing and water control for projects offshore Mexico. Chacon has a BS degree in chemical engineering from the University of Carmen and has four years of experience in the oil industry.

|

|

|

|

Larry Eoff is a Chemist in the Conformance Group at the Halliburton Energy Services Technology Center in Duncan, Oklahoma. Eoff has been with Halliburton 16 years in Conformance And Cement Product Development. Eoff earned a BS degree in chemistry from the University of Central Arkansas and a PhD degree in organic chemistry from the University of Arkansas.

|

|

|