An industry survey was used to develop flowcharts to determine best practices with coalbed methane reservoirs.

Sunil Ramaswamy, Walter B. Ayers and Stephen A. Holditch, Texas A&M University

Before selecting a completion method for a coalbed methane (CBM) well, nine factors should be considered: investment required; number of coal seams encountered by the borehole; expected production rate; reserves in the various coal intervals; coal-seam permeability and gas content; type of stimulation treatment expected, if any; wellbore stability problems; future workover requirements; and artificial lift requirements, if any.

To establish a set of best practices for CBM production, relationships among the selection of drilling, completion and stimulation methods and geological characteristics of coalbeds were clarified. Pertinent literature was reviewed and industry experts were queried to assure that the latest engineering practices were incorporated in the study. Industry experts from operating, service and consulting companies were selected on the basis of their expertise and the CBM basins where they operated.

QUESTIONNAIRE OF CBM BEST PRACTICES

A questionnaire was used to gather input from industry experts. Knowledge gained through literature review of CBM drilling, completion and stimulation practices in different basins was used to design the questionnaire. Industry experts were asked to rank the parameters that influence their decisions when selecting drilling, completion and stimulation methods.

Critical geological parameters that should be considered when selecting engineering technologies for CBM reservoirs were identified. To determine the importance of the each parameter, the ranks assigned by experts were averaged. Next, the different CBM drilling, completion and stimulation practices were listed, and the experts were asked to rank the geological parameters that are important in selecting each.

Using the experts’ responses, a list of critical geologic parameters and the range of values suggested by them was made. The questionnaire also included a separate section to determine the geologic factors that influence the selection of hydraulic fracturing fluids for CBM wells. The questionnaire was sent to 22 industry experts, of which six experts completed and returned it.

SURVEY RESULTS

Survey results indicated that when selecting drilling and completion types and stimulation fluids, most experts take all geological parameters into consideration. The most important parameters are depth of coal occurrence, thickness of coal seams, permeability, gas content and reservoir pressure. Some factors, such as coal-seam dip, coal-seam areal extent and vertical offset of coalbeds from aquifers, were added to the parameter list based on the experts’ feedback.

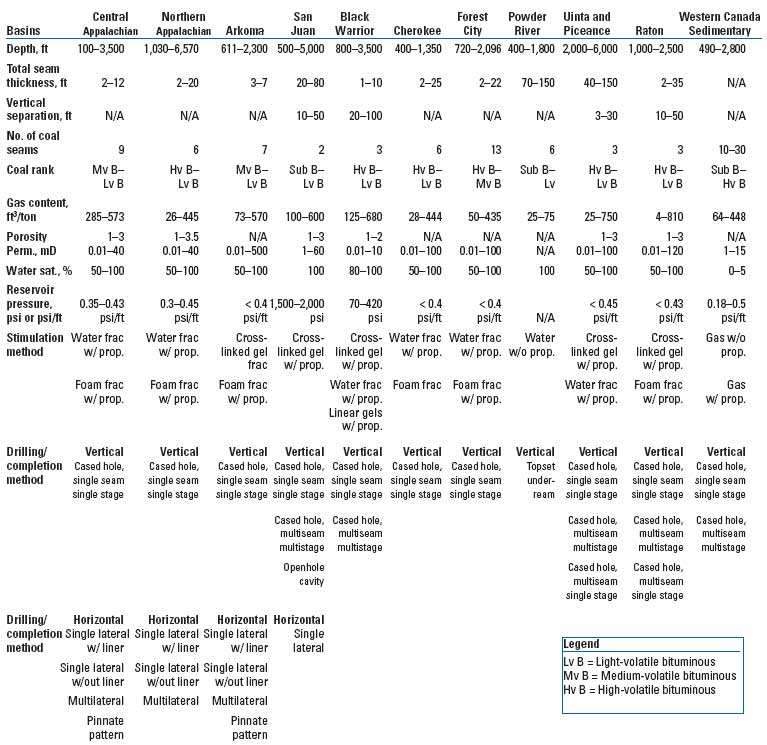

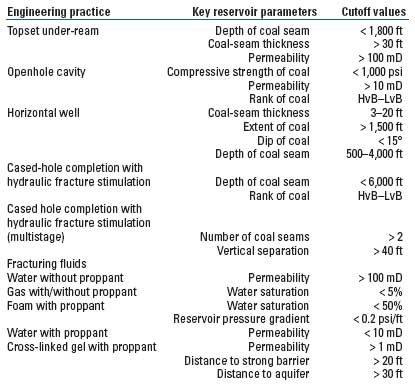

Drilling, completion and stimulation methods used in US CBM reservoirs were identified based on the literature review and questionnaire, Table 1. Geologic parameters that influence industry experts’ decisions concerning the best CBM engineering practices for specific geologic settings were also identified. Using this knowledge, two decision charts were made. One chart was used to select the best drilling, completion and stimulation methods for CBM wells (Fig. 1), and the other was used to select the best fracture stimulation fluids for specific geologic settings, Fig. 2. These decision charts were captured in a software routine to facilitate their use.

|

|

Fig. 1. Decision chart for selection of drilling and completion method in coalbed methane wells.

Click image to enlarge.

|

|

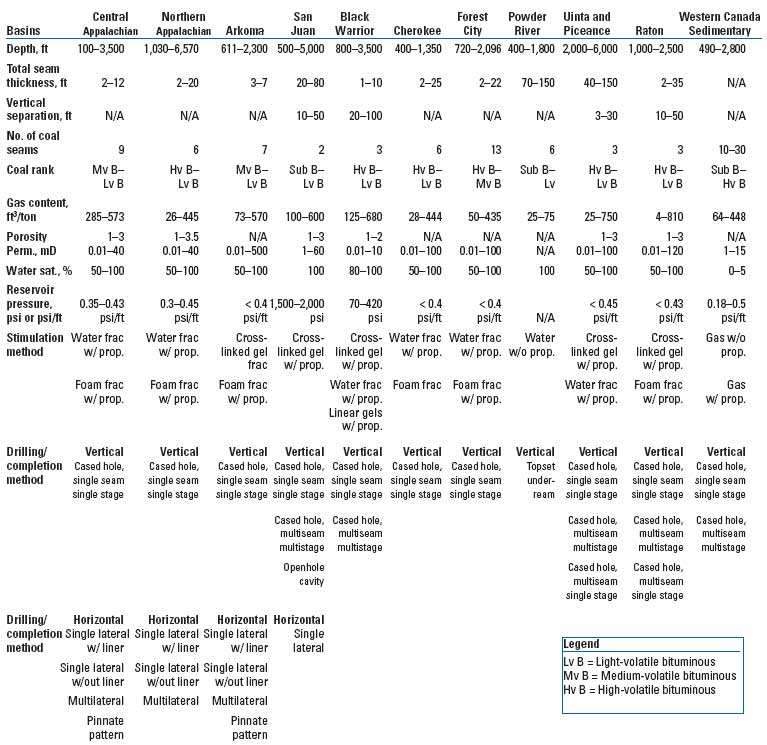

TABLE 1. US CBM basin properties and engineering practices

Click table to enlarge. |

|

|

|

|

Fig. 2. Decision chart for selection of fracturing fluid in coalbed methane wells.

|

|

PARAMETERS OF THE DRILLING AND COMPLETION CHART

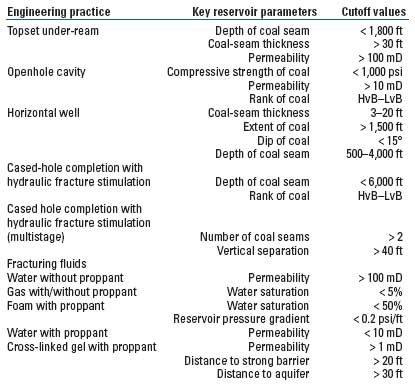

The decision chart for selecting optimum drilling and completion practices for CBM reservoirs used the following reservoir parameters: net seam thickness, coal-seam gas content, coal rank, coal-seam depth, permeability, areal extent of coal, dip of the coal, number of coal seams and vertical distribution of coal. Below is a brief explanation of importance of some of these geologic parameters. The cutoff values of these geological parameters are summarized in Table 2.

TABLE 2. CBM engineering practices cutoff values

Click table to enlarge. |

|

|

Net seam thickness influences whether a horizontal well or vertical well should be drilled. It also influences the selection of completion methods, such as the topset under-ream method used in Powder River Basin (net seam thickness greater than 30 ft). For drilling horizontal wells, the industry response indicated that net seam thickness should range from 3 ft to 20 ft.

The coal seam’s gas content is important to the commercial success of the well. Only the Fort Union coals of Powder River Basin and Horseshoe Canyon coals of Western Canada Sedimentary Basin have successful CBM plays with gas content less than 140 ft3/ton. In both cases, coal-seam permeability is high, depth is shallow and net seam thickness is very high. These factors help reduce completion and stimulation costs, thus making these projects successful. The value of 140 ft3/ton was selected as the boundary between high and low CBM content on the basis of industry response to the questionnaire.

Coal rank plays an important role in the gas content and cleat development, and thus permeability. Most CBM production is from high-volatile to low-volatile bituminous coals. To date, anthracitic coals have not had economic CBM production. Only the Powder River and Western Canada Sedimentary Basin coals have had economic production from sub-bituminous rank coals.

Coal-seam depth influences a number of decisions in drilling and completion. To date, all CBM horizontal wells were in coal seams between 500 and 4,000 ft deep. Similarly, topset under-ream has been demonstrated successful only at depths less than 1,800 ft. CBM has not been successfully produced from seams deeper that 6,000 ft because of very low coalbed permeability. CBM can be economically produced from depths greater than 6,000 ft only if sweet spots can be identified.

Permeability is the most important factor in deciding whether to complete a CBM well, and it is important in deciding the type of completion and stimulation methods to be used.

The areal extent and dip of the coal are important parameters to consider when deciding whether to drill horizontal wells.

The number of seams and vertical separation of coal seams are used to decide between single-stage (single/multiseam) and multistage completion. Two disadvantages with the single-seam completion are:

- It may cause thin coal seams to be ignored, and, thus, cause large areas in the basin to remain uneconomic.

- It requires a much larger number of CBM wells, with increased capital costs and land disturbance, to produce the same quantity of gas as can be produced from fewer wells using multi-seam completions.

Multi-seam completions are used in Black Warrior, Raton and Uinta Basins. The wells may be stimulated in a single fracture treatment or several treatments, depending on distance between seams.

APPLICATION OF DRILLING AND COMPLETION CHART

To apply the drilling and completion decision chart, begin with coal-seam thickness. There have been no cases of economic CBM production where net coal thickness is less than 3 ft. Hence, there are no recommended completion methods for this case.

Next, the decision chart says to check the gas content. For cases where gas content is less than 140 ft3/t and the rank of coal is less than high-volatile bituminous, only Powder River Basin and Horseshoe Canyon CBM plays have been successful. Hence, where geologic conditions are not similar to those plays, CBM gas has not been economically achieved.

If gas content is low (< 140 ft3/t), check net coal thickness and coal depth. If net seam thickness exceeds 30 ft and coal depth is less than 1,800 ft, evaluate coalbed permeability. If permeability exceeds 100 mD, then Powder River Basin conditions are satisfied, and it can be conclude that topset under-ream completions are appropriate. If permeability exceeds 1 mD but is less than 100 mD, then Horseshoe Canyon conditions are satisfied, and a vertical well with cased-hole completion is an option. If net coal thickness is less than 30 ft or the depth exceeds 1,800 ft where gas content is less than 140 ft3/t, then it can be concluded that economic gas production has not been achieved.

Topset under-ream CBM completion is used exclusively in the Powder River Basin, which is characterized by high-permeable, low-rank, low-gas content, shallow and thick coals, Table 1. As the coals are shallow, the drilling cost is less. The wells are left openhole. As the coals are highly permeable, the cost of stimulation involved is also less. Average coal thickness in the basin is more than 30 ft, thus providing economic gas volumes even though gas content is very low. The main geological parameters that affect selection of this method are depth of the coal seam, thickness of the coal seam and permeability. The low drilling, completion and stimulation costs associated with this method make it successful even though gas content and coal rank are low. When gas content and coal rank are low, topset under-ream method is most successful if the reservoir is shallow, thick and highly permeable (> 100 mD).

Semi-anthracite and anthracite. For the cases where coal rank is semi-anthracite or anthracite, gas content may be high, but the rates of gas desorption are very low. To date, there have been no successful cases for CBM production from these high-ranking coals. Hence, it is not economical to complete CBM wells under these conditions.

If compressive strength of the coal is less than 1,000 psi, permeability should be checked. If permeability exceeds 10 mD, then San Juan Basin fairway conditions are satisfied, and openhole completions should be considered.

Openhole cavity completion. The main geologic factors that make this completion successful have been identified as the low compressive strength of coal, high permeability, high gas content and reservoir overpressure, Table 1. Apart from the fairway of San Juan Basin, this completion type has been successful in one part of Bowen Basin, Australia. In all cases, it has been successful where compressive strength of the coal is less than 1,000 psi and permeability was greater than 10 mD.

If the compressive strength of coal is less than 1,000 psi and permeability ranges from 10 mD to 100 mD, cavity completion method is an option. In cases where cavity completion is successful, cased-hole completions with hydraulic fracture stimulation are a viable option for completing the CBM well. The decision to select either openhole cavity completion or cased-hole completion is based on the operator choice, availability of equipment and the cost involved.

Where permeability is less than 10 mD and compressive strength is greater than 1,000 psi, net coal thickness should be checked. If net coal thickness ranges from 3 ft to 20 ft, check depth and areal extent of the coal and the dip of the coal seam. If the depth ranges from 500 ft to 4,000 ft, areal extent of the coal is more than 1,500 ft, and dip is less than 15°, then the conditions are good for horizontal wells.

Horizontal CBM wells have been successful in the Appalachian, Arkoma and some parts of the San Juan Basins. Coal-seam thickness varies from 3 ft to 20 ft in both the Appalachian and the Arkoma Basins. Depth ranges from 500 ft to 4,000 ft, and gas content exceeds 140 ft3/t in both basins. From the industry response to the questionnaire, coal extent should be at least 1,500 ft from a well, and coal-seam dip should be less than 15°. Thus, depth, thickness, areal extent and coal-seam dip are the main geologic factors when choosing horizontal wells.

From the survey results, horizontal well completion is an option when coal thickness ranges from 2 ft to 20 ft, coal areal extent is more than 1,500 ft, depth ranges from 500 ft to 4,000 ft and coal-seam dip is less than 15°.

Horizontal well production rates are 5 to 10 times greater than those of vertical wells. However, in cases where horizontal wells are successful, vertical wells with cased holes and hydraulic fracture stimulation are also successful as in San Juan, Arkoma and Appalachian Basins.

If the decision has been made to drill a horizontal well, then further decisions may be made concerning whether to drill a single-lateral or multilateral well, based on coal permeability.

Multilateral wells in pinnate pattern have been drilled in Arkoma and Appalachian Basins. In addition to the conditions that are needed for drilling horizontal wells, multilateral wells have been drilled in low-permeability coals (< 1 mD). Other geologic conditions to consider when selecting pinnate wells are coal that is free of intrusions and other geological structures, such as folds and faults. If the conditions for horizontal wells are satisfied and the permeability of the coal is less than 1 mD, then drilling multilateral wells is the best option.

For cases where coal depth exceeds 4,000 ft or is less than 500 ft, areal extent of coal is less than 1,500 ft and/or coalbed dip is greater than 15°, check whether coal depth exceeds 6,000 ft, and if so, CBM production is not economical, based on experience to date. For all the other remaining conditions, cased-hole completions with hydraulic fracturing are the best completion and stimulation method.

Cased-hole completion. This method is used in the producing CBM basins, other than the Powder River Basin. This method has been used for producing gas from all types of coal seams other than low- and high-rank coals, high-permeability coal seams (> 100 mD) and low-gas content coals (< 140 ft3/t). It is used with hydraulic fracture stimulation. The type of hydraulic fracture design differs from basin to basin. The cased-hole completion can be single-stage or multistage completion. Multistage completion is used when stimulating more than one coal seam when seams are separated by more than 40 ft, such as Black Warrior, Raton and Uinta Basins. Hence, cased-hole completion with hydraulic fracturing is an option when gas content of the coal is more than 200 ft3/t and permeability is less than 100 mD.

STIMULATION CHART

The decision chart for selecting the stimulation fluid for CBM reservoirs is based on the following reservoir parameters: permeability, water saturation, reservoir pressure, distance to aquifer and distance to strong barrier. Parameters for stimulation fluid use can be found in Table 2.

Fracturing without proppant. This method of completion is used in Powder River Basin to stimulate wells when using topset under-ream completion. This method is used to improve reservoir connectivity to the wellbore in very high permeability reservoirs. Permeability is the main deciding factor for using of this method; it is used where permeability exceeds 100 mD. Next, check the fluid decision chart for formation water saturation. If it is less than 5%, then fracturing with gas is the best option. If the formation water saturation is less than 50% but more than 5%, then fracturing with foam and proppant is the best option. Fracturing with foam and proppant is also the best option when the reservoir pressure gradient is less than 0.2 psi/ft.

Fracturing with gas. Water saturation is the most important factor in deciding this stimulation method. It is used in dry coals or coals that swell when they come in contact with water or other liquids. Fracturing with gas is used in the Horseshoe Canyon coals in the Western Canada Sedimentary Basin. These coals have zero to very low water saturation.

Foam fracturing is used in Appalachian, Arkoma, Cherokee, Forest City and Raton Basins. All of these basins are characterized by low formation pressure and low water saturation, which are the two major factors in determining the use of foam as the fracturing fluid. Where water saturation of coal reservoirs is high (> 50 %) and the reservoir pressure gradient is more than 0.2 psi/ft, then fracturing with water or gelled fluids with proppant is an option.

Water. Slick water has been used as a fracturing fluid in Appalachian, Arkoma, Cherokee, Forest City, Black Warrior, Raton and San Juan Basins. In the zones where water is used for fracture stimulation in these basins, the reservoir is normally pressured or overpressured, water saturation is high, and permeability is less than 10 mD.

Cross-linked gel. Cross-linked gel has been used as a fracturing fluid in Appalachian, Arkoma, Cherokee, Forest City, Black Warrior, Raton, San Juan, Uinta and Piceance Basins. In the zones where cross-linked gel fracturing is used, the reservoir is normally pressured or overpressured, water saturation is high and permeability is greater than 1 mD. For cases where permeability of the formation is 1-10 mD, both water and cross-linked gel fracturing can be used as fracturing fluids. Some other factors, such as distance to the nearest aquifer and distance to strong barrier, also influence selection of water or cross-linked gel as the fracturing fluid.

General fracturing practices. Based on the decision charts, a visual basic program for selection of drilling, completion and stimulation best practices in CBM reservoirs was developed. On the basis of the experts’ responses the following additional general practices are common when stimulating vertical wells:

- The pre-pad volume pumped before a fracture job is about 30-40% of the total volume of the pad

- The pad volume is about 10-20% of the total treatment volume

- The total volume of fracturing fluid pumped is about 50 bbl/ft of net coal thickness

- The injection rate of treatments ranges from 1 bpm/ft to 2 bpm/ft of net coal thickness

- The type of proppant pumped is normally determined on the basis of targeted fracture conductivity value

- The size of the proppant normally used is 20/40 mesh, unless the permeability value is greater than 30 mD, in which case the mesh size used is 12/20.

CONCLUSION

Drilling, completion and stimulation methods used in the CBM reservoirs differ from basin to basin, and within basins, owing to variations in geologic setting. The geologic parameters that affect selection and success of CBM drilling, completion and stimulation practices are coal depth, thickness, areal extent, dip, permeability, rank, gas content, formation pressure, water saturation, and compressive strength, as well as vertical distribution of coalbeds and distance to fracture barriers and aquifers.

Topset under-reamed openhole wells are used primarily in the Powder River Basin. Reservoir parameters and the associated range of values that influence the selection and the success of this method are: depth less than 1,800 ft; permeability greater than 100 mD; and thickness greater than 30 ft.

The openhole cavity completion method is successful primarily in the fairway region of the San Juan Basin. Reservoir parameters and the corresponding range of values that influence the selection and the success of this method are: compressive strength less than 1,000 psi; permeability greater than 10 mD; and coal rank: high- to medium-volatile bituminous.

Horizontal wells are successful in the Arkoma, Appalachian and San Juan Basins. Reservoir parameters and the corresponding range of values that influence the selection and the success of this method are: thickness of 3 ft-20 ft; areal extent of the coal greater than 1,500 ft; dip of the coal seam less than 15°; and depth of 500-4000 ft.

Multilateral wells are successful in the Arkoma and Appalachian Basins. Reservoir parameters that influence the selection of this method are similar to those of horizontal wells. A key factor is that multilateral wells are successful where permeability is less than 1 mD. Multilateral horizontal wells drilled in pinnate pattern have the highest recovery efficiency of any type of CBM completion method with more than 85% recovery.

The cased-hole completion with hydraulic fracture stimulation is the most commonly used completion and stimulation method and may be applied to all coalbed reservoirs having permeability value less than 100 mD.

For coalbeds having permeability greater than 100 mD, water fracturing without proppant should be used. For dry coals, gas fracturing is the best stimulation method. For coalbeds having low water saturation and low reservoir pressure, foam fracturing is best. For coalbed reservoirs having permeability of 10-100 mD, cross-linked gel fracturing with proppant should be used. For coalbeds having permeability less than 1 mD, water fracturing with proppant should be used. For CBM wells with more than one coalbed, multistage fracturing is the best stimulation method if the seams are separated by a distance of more than 40 ft.

|

THE AUTHORS

|

| |

Sunil Ramaswamy works as a Reservoir Engineer for consulting services in Schlumberger Asia Services Limited. His past experience involves working as an Application Engineer for development of open cast coal mines for Larsen and Toubro Limited, India. Current interests include development of unconventional reservoirs, development of CBM reservoirs in India and enhanced recovery processes. He has an MS degree from Texas A&M University in petroleum engineering and a BS degree in mining engineering from National Institute of Technology Karnataka, Surathkal.

|

|

| |

Walter B. Ayers is a Visiting Professor in the Petroleum Engineering Department at Texas A&M University. He teaches courses in formation evaluation, reservoir description, unconventional oil and gas reservoirs and petroleum geology. Ongoing research includes: shale, tight sand and coal reservoirs; CO2 sequestration and enhanced methane production from coalbeds; and production optimization of conventional reservoirs. Ayers holds a PhD in geology from University of Texas at Austin and MS and BS degrees in geology from West Virginia University.

|

|

| |

Stephen A. Holditch is head of the Department of Petroleum Engineering at Texas A&M University. He previously worked for Schlumberger, and served as president of Holditch & Associates from 1977 to 2000. His firm provided petroleum engineering technology involving the analysis of low-permeability gas reservoirs and the design of hydraulic fracture treatments. Dr. Holditch also has been a Production Engineer at Shell Oil in charge of workover design and well completions. He joined the Texas A&M faculty in 1976.

|

|

|