New products

New product and service offerings from company press releases

Mitigating drilling vibrations

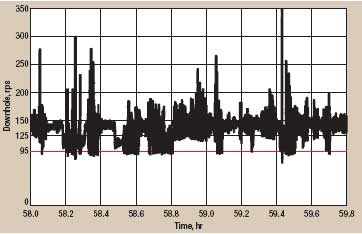

Drilling vibration has been identified by many operators as the leading cause of non-productive time, ranging from simple drilling inefficiencies to twisting off the drillstring due to fatigue failure. Premature bit, downhole drive system and logging tool failures have all been attributed to dynamic conditions, such as bit whirl, pipe whirl and stick-slip. Rather than address these issues individually, ReedHycalog has adopted a more holistic, process-orientated methodology. ReedHycalog Drilling Dynamics Solutions attack this problem by prediction, mitigation and validation. Prediction of drillstring behavior is achieved through VibraSCOPE drillstring dynamics modeling software. The user enters the details of the drillstring and BHA and imposes a force input. The software predicts those parameters that will likely cause resonant axial, lateral and torsional vibrations. The output identifies critical weight and rpm ranges that avoid resonance and reduce the risk of initiating damaging vibrations. From the predictions come recommendations from solutions packages, including Demanding Drilling Solutions, Hard Formation Solutions, Large Diameter Solutions and Hole Opening Solutions. With its unique geometry, the V-Stab vibration-dampening tool provides a mechanism for disrupting resonant vibration modes, reducing the number and magnitude of shocks that occur during drilling. It disrupts vibration because its asymmetric cross-sectional geometry provides variable freedom of movement of the drillstring, and an eccentric mass that applies centripetal forces to the string. The combination of variable movement and centripetal forces breaks up resonance and dampens the magnitude of shock waves For validation, measurement of the actual drillstring dynamic behavior is important due to the complex nature of the drillstring and wellbore interaction. To fully understand the effects of the drillstring geometry, drive type and other downhole tools, actual measurements are taken during drilling operations with the BlackBox Downhole Dynamics Recorder. At 23/4-in. diameter, the tool’s size allows for flexible placement in multiple locations, if required, along a single drillstring. It allows post-well analysis of dynamic behavior of the drillstring, enabling recommendations to optimize the drilling process.

Online rig data ODS-Petrodata announced the launch of a major new development of its flagship rig locator publication, Offshore Rig Locator (ORL). Beginning in 2008, existing monthly electronic and hardcopy ORL subscriptions are replaced by a single real-time online web version, available to all subscribers. The new version provides a highly configurable and detailed search tool providing real-time access to the latest contract and specification data on the offshore drilling rig fleet worldwide. As well as searching, displaying and re-sorting current rig data, users can download search results in spreadsheet format. The rig locator will also continue to be produced in pdf format.

Stand-off band Volant Products Inc. has developed a new hydro-formed product, the H.D. StandOFF Band, manufactured from either 0.187-in. or 0.250-in.-wall ERW tube. Stand-off bands are generally manufactured using a 0.118-in. plate, stamped, rolled and welded, or have bars welded on the outside of a tube to act as the ribs. The hydro-forming process uses high-pressure water to form the rib on the tube. The profile is smooth, with no sharp edges or secondary components to be stripped off. A large contact area better enables the centralizing device to travel through the casing or wellbore. The manufacturing process also enables a rib height, or diameter, that better centralizes the casing, liner or production tubing, not just to keep it off the edge of the wall.

Plaform support vessel Rigdon Marine Corp. announced that the Grand Slam, their fourth 4000 Class plaform support vessel (PSV), was delivered by Bollinger Shipyards in Lockport, Louisiana. The Rigdon 4000 Class PSV was named a “Significant Boat of 2007” at the WorkBoat Trade Show in New Orleans. The Grand Slam is a 190-ft × 46-ft × 18-ft diesel electric, DP-2 PSV that features a capacity of 4,000 bbl of liquid mud in an oval, self-cleaning, segregated tank system. The PSV will also include three Z-Drives and two large forward tunnel thrusters. The PSVs are capable of serving a wide array of marine applications in all water depths. Six more Rigdon 4000 class PSVs will be delivered throughout 2008. |

|||||||||||