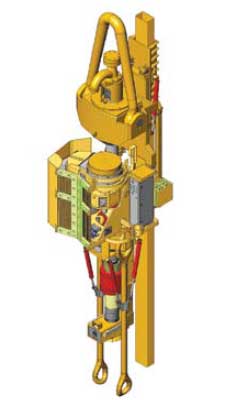

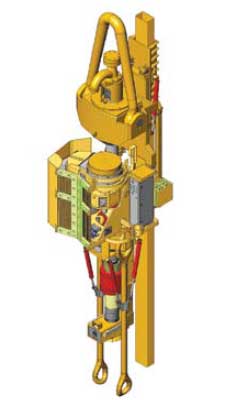

Tesco Corp. added a 750-ton AC top drive to its lineup, enhancing its range of top drives to cover 95% of the industry’s onshore and offshore needs. The latest unit, the 750ECIX1350/1500, features Permanent Magnet (PM) motors, a new Variable Frequency Drive (VFD) system, and provides up to 1,500 hp, Fig. 1.

|

|

Fig. 1. Tesco has added a 750-ton AC top drive with permanent magnet motors.

|

|

The new VFD system is based on commercial drive technology and uses the new eDrive interface between the VFD and the DRS Power Technologies’ PA44 PM motors. The control interface and motor characteristics are configured specifically for the control requirements specified by DRS and Tesco. The drive logic is programmed to allow the ECI and ECIX top drive systems to operate at constant speed for drilling ahead or with constant torque, as when making or breaking drillstring members. Further, the drive logic permits speed and torque limits to be set.

The eDrive replaces the MD500-style VFD presently used on the company’s ECI series top drives. Since the air-cooled drive is based upon common drive technology, maintenance and troubleshooting at the rig are simplified and cost of ownership is reduced.

The new top drive uses three DRS PA44 PM motors. The basic ECIX will deliver 1,350 hp at the quill, using three 450-hp PA44s. A high-performance upgrade is available to deliver 1,500 hp. It uses the same PA44 platform but with each of the three motors producing 500 hp. The VFD and PA44 motor combination is a master/slave configuration of three drives and three motors. Multiple drives and motors allow the top drive to operate at reduced horespower and torque output, even if a VFD or motor should fail.

The new top drive comes with an integrated swivel configuration, eliminating the oilfield connection typically necessary between the top drive quill and the swivel, resulting in a shorter, more reliable load path. The ECIX can be supplied with a dolly guide rail torque arrest system or with the traditional torque track and torque bushing. The grabber can accept drillstring components up to 10½-in. diameter.

The 750ECIX is a replacement for aging 750-ton systems on- or offshore. The ECI and ECIX models are available as CE marked and ATEX certified.

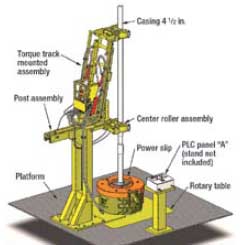

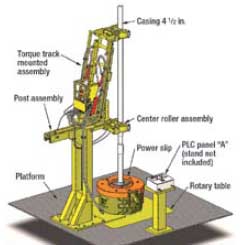

Tesco also offers a combination power spider/elevator and a Portable Tubular Stabbing System (PTSS) that, when used together, provide a fully automated system, Fig. 2. The load rating for the power spider/elevator is 350 ton (API 8C) when used as an elevator, and 500 ton (API 7K) when used as a spider. Both systems are hydraulically powered and can be controlled manually or through electric-over-hydraulic control. The systems can also be used independent of one another.

|

|

Fig. 2. A combination power spider/elevator and a portable tubular stabber provide a fully automated system for tubular products.

|

|

When used with the company’s Casing Drive System, drillpipe is untouched by human hands. The level of automation provided by using the equipment in combination eliminates up to four rig- or casing-crew members working on the rig floor and in the derrick, increasing safety as well as performance.

The low-profile spider is only 25 in. above the rig floor and fits in a 17½-in. rotary table. Larger rotary table sizes can be accommodated with adapters. The power spider/elevator can accommodate drill pipe, tubing and casing sizes from 4 in. to 13 in. by using adapters. Torque capacity is 54,000 ft-lb on 133⁄8-in. casing with no axial load, eliminating backup tongs when running the first joints. The dies are 14 in. long, and produce effective gripping with less tubular product damage.

The spider’s split design enables easy installation and removal without lifting the spider over the tubular, which increases safety. The spider hydraulically centers the tubular from the first joint to job completion while maintaining alignment through the rotary table and blowout preventer. The spider holds torque at low string weights, eliminating backup chains or tongs.

The PTSS further mechanizes the stabbing process and provides accuracy and repeatability during stabbing operations. The system can be mounted on the rig floor or to an existing Tesco monorail-style torque-restraint system. If the rig does not have a torque track, the PTSS is mounted on the rig floor in conjunction with the power spider/elevator.

With the PTSS and power spider/elevator system combination, only one crew member on the rig floor is required for visual thread inspection and lubrication. The crew member is not in contact with the tubular in motion, significantly reducing risk during the stabbing operation.

Alignment is adjusted on the arm or slider between the arms and the hydraulic cylinders. Once adjusted, the system will repeat the same stabbing position.

|