Kem-Tron Technologies has developed a Human Machine Interface (HMI) software control system that optimizes process performance. Key performance breakthroughs in the newest HMI Technology (patent pending) take onboard laboratory analysis developed in the Reardon vortex test and apply these data into a computer-managed, chemical-feed system.

The vortex test determines the chemical dosage needed to develop a hard flocculation. When chemicals are added at the proper dosage, colloidal solids with particle sizes greater than 5 micron are removed from the drilling fluid waste by particle charge destabilization with a high cationic-charged/low molecular weight organic polymer. These particles are aggregated together to form a “hard floc” with the addition of a varying anionic-charged/high molecular weight organic polymer. Formulas convert the chemical dosages derived from the test into pump units (gpm).

|

|

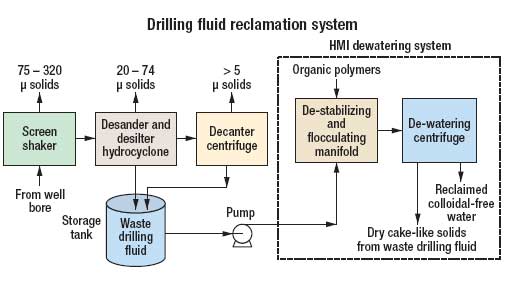

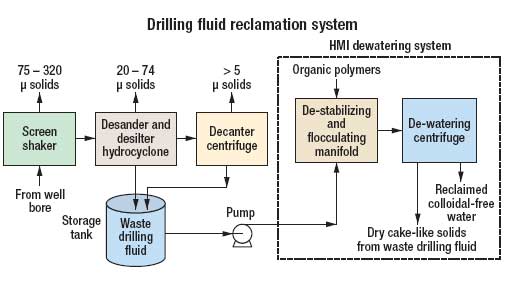

Fig. 1. The HMI dewatering system adjusts liquid flow, product feed, chemical demand and process parameters to produce dry solids and clear water.

|

|

The software adjusts liquid flow, product feed, chemical demand and process parameters. Devices are controlled from a single, touch-screen, process management control center.

The dewatering products are dry solids and clear, process-effluent water. Dry solids reduce trucking and hauling costs. Clean solids mean land application is regulated in a different way. The clean effluent water becomes available for process water, or it can be filtered through the company’s Membrane Filtration Modules, which can provide high-purity water for onsite application such as chemical feed water, laboratory test water, high-purity wash water or even boiler water. Reusing the processed water can have a dramatic bottom line impact.

“Our finished product after using Kem-Tron’s dewatering system has always been environmentally safe. The chemical process leaves us with good clear water, and we get about 75-85% dry solids waste, which means our dump truck solids waste removal program is maximized versus transporting wet loads, which are environmentally unsafe,” said Mark Schmalzried, a Closed-loop Dewatering Specialist with Western Bentonite.

The environmentally-controlled, container-dewatering systems are built in 40-ft and 20-ft containers. All of the features of the 40-ft container are engineered to maximize process performance in a small footprint for offshore dewatering applications.

Manufactured near Houston’s Space Center in a new 400,000 ft2 production complex, the company can produce a new HMI Dewatering System every three weeks. Capacity increases are planned to double in 2010. For more information see www.kemtron.com.

|