An innovative use of downhole gauge and reversed gas lift valves solves a major problem while tripling pre-wellwork liquid-loaded production rate.

Peter O. Oyewole, BP; and Jason Jones, Schlumberger

Elegant in its simplicity, gas lift technology has benefited from many technological improvements over the years. Pressure, temperature and depth ratings have been extended, even as the valves were made more compact. Mandrels have been improved to facilitate change-out, and to enable their use in increasingly cramped diameters. Some of the latest improvements have been made to the valves themselves, including adding a Venturi choke to boost the injection gas velocity to achieve a critical flow regime. This prevents “heading” that causes instabilities in the gas flow leading to uneven mixtures of gas and liquid. The improvements have resulted in high-performance technology that has much broader operating limits.

Faced with severe production problems in one of its San Juan Basin Coal Bed Methane (CBM) wells in Colorado, BP resorted to versatility in the use of standard production equipment. The well was producing 400-500 Mcfd of gas and was experiencing liquid-loading problems due to beam-pump failure, which impaired production. Formation pressure was low, about 200 psi, and there were concerns that without some way to unload the liquid there would be potentially damaging backpressure on the formation. Initially, the liquid levels were being controlled by a beam pump.

SYSTEM DESIGN

Instead of the plugging-prone pumps, a gas lift completion was designed. Among the specifications was a method to prevent the ubiquitous coal fines from plugging the gas lift valves and orifices. BottomHole Flowing Pressure (BHFP) was also minimized because CBM wells require very little BHFP to attain maximum production rates. The natural cleating system of the coal provides many high-conductivity pathways for the gas to flow out of the formation as long as there is little or no backpressure due to liquid in the column. Nevertheless, to ensure that production rates were optimized, the operator installed a sensor package to enable continuous monitoring of pressure and temperature.

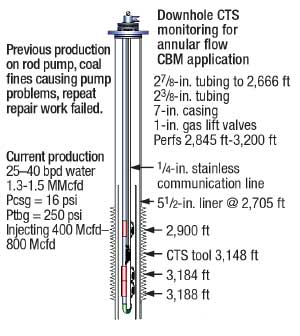

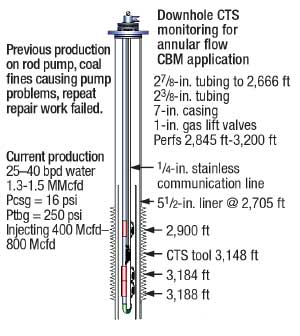

Other design constraints included the formation characteristics and the existing wellbore architecture. On the formation side, the static pressure was less than 200 psi. A significantly low BHFP is required to achieve desirable gas flowrate. As for the well architecture, the lowest perforations were just 1-2 ft above plugback TD, leaving no rat hole to work with. The well was originally an openhole cavitated well with 7-in. casing to the top of the coal. A 5½-in., 15.5-lb/ft liner was run in the open hole during the conversion from flowing well to beam-pumping well from 2,705 ft to TD in 2005. The liner was perforated from 2,845 ft to 3,200 ft, Fig. 1. Injection gas from the central delivery point was available, but pressure at the wellsite was less than 300 psi, creating additional design constraints.

|

|

Fig. 1. The well sketch shows the location of the tandem gas lift valves at 3,184 ft and 3,188 ft, with the IPO valve at 2,900 ft. The dual-ported gauge package is located at 3,148 ft.

|

|

APPLICATION

A tapered production string was designed consisting of 2 7/8-in. tubing from surface to 2,666 ft, nippled down to 2 3/8-in. tubing from that point to the BHA. Gas was injected down the tubing and out through the gas lift valves, lifting the well liquid in the tubing/casing annulus. This reverse-valve technique would prevent valve and orifice plugging. A Phoenix gauge was run at the same levels as the gas lift valves, and was linked to surface via a ¼-in. stainless control line containing the gauge cable. The cable was ported at the wellhead, so data could be transferred directly to the field SCADA system or stored on a portable memory device. The gauge was housed in a gauge protector and was provided with a ported coupling enabling it to measure internal tubing pressure. The ported coupling replaced a standard tubing collar at the desired measure point. The bull plug at the bottom of the tubing ensured that the pressure drop was taken across the gas lift valves and did not permit gas injection into the perforations.

The SCADA system was measuring wellhead casing pressure, tubing pressure and flowline pressure, as well as the liquid and gas flowrates. The downhole-gauge package measured static and BHFP in both tubing and annulus. Its function was to provide fine drawdown control and continuous analysis of well conditions at the injection points. It could also be used to perform pressure-buildup transient analysis.

Dual 1-in.-orifice valves with check valves were run as deep as possible. Final depths chosen for the valves were 3,188 ft and 3,184 ft, respectively. The use of dual valves allowed high injection volumes at low injection pressure. Dual valves also ensured that a backup was available in case of plugging. Setting the valves deep into the perforated zone minimized formation backpressure. To help commence production when the new system was initiated, an Injection Pressure Operating (IPO) valve, set for 280 psi, was run above the orifices at 2,900 ft. The Cable-To-Surface (CTS) system gauge package was set at 3,148 ft with its gauge placed near the operating valve to measure differential pressure across the orifice. Both tubing and annular-pressure sensors were ported to the same depth.

The completion architecture was designed to prevent entry of coal fines that could possibly plug the valves. By using annular flow for the liquid and lifting gas from the bottom of the perforation, the majority of coal fines would be swept up and away from the completion.

Successful completion required sufficient injection gas pressure and rate, annular side-pocket gas lift mandrels to overcome inside diameter restrictions and to facilitate change-out of the valves if required, and downhole sensors for production optimization.

RESULTS

The installation of the CTS gauge gave a better understanding of reservoir performance, as well as well unloading. The combination of the downhole gauge with gas lift valves will save workovers in future.

After well work, gas production more than tripled to 1,500 Mcfd. This rate was sustained for months, with the exceptions of some planned and unplanned surface-facility shutdowns. The production-conduit pressure gradient fell as low as 0.013 psi/ft when surface casing pressure was 14.4 psi and the downhole casing pressure was 56.8 psi. The injection dry gas gradient was about 0.008 psi/ft, and the pressure drop across the orifices fell as low as 67 psi during gas injection. Thus data is very close to the predicted design model. Overall, this project has been deemed a success. The well delivered a significant increase in sustained production volumes while production losses due to pump failures and resulting interventions were eliminated. The installation of the gas lift completion yielded good economic returns and the CTS system provided data for well performance monitoring and production optimization. This is the first time tandem operating valves have been deployed successfully on a gas well application, allowing reduction of trapped pressure in the tubing as well as providing a backup system. Injection volume was doubled while maintaining low pressure.

It was unique in that tubing pressure was used to operate the unloading valves instead of annular pressure. Typically, one does not operate these valves below 300 psi; this one operated successfully at 280 psi. The well was unloaded from the lower operating valve instead of the IPO valve.

Future updates include automating the system by using real-time data from the downhole and surface sensors to automatically moderate injection rate and pressure, both of which currently are manually controlled.

|

THE AUTHORS

|

|

|

Peter O. Oyewole is the artificial lift production engineer for BP America Inc. He earned an MS in petroleum engineering at University of Houston and a BS degree in petroleum engineering at the University of Ibadan, Nigeria.

|

|

|

|

Jason Jones is a field engineer for Schlumberger, focusing on gas lift and completions. He earned his BS in mechanical engineering from Texas A&M University. He is a member of SPE.

|

|

|