RESERVOIR CHARACTERIZATION

Information-driven life-cycle reservoir management

Between-well data from crosswell imaging is one key to optimizing recovery.

Raul Ortiz, Raul Ortiz and Associates

While overall increased drilling activities and challenging drilling applications are capturing the headlines, there is a quieter, but potentially more significant movement within the oil and gas industry. This new direction emphasizes using information to manage the reservoir for optimal reserves recovery over the full life cycle.

Today, despite the many advances in reservoir characterization technologies and techniques, the recovery factor for oil reservoirs still averages less than 40%. It is estimated that in the US there are in excess of 374 billion bbl of stranded oil with almost 100 billion bbl recoverable. Extrapolated on a global basis, bypassed oil constitutes perhaps the final frontier for the industry, with well over 1 trillion bbl in play. With crude prices high, and new exploration involving significant expense and risk, there is a great deal more emphasis on optimizing the recovery rate from existing and new reservoirs.

VERTICAL INFORMATION GAP

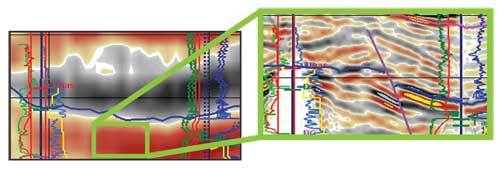

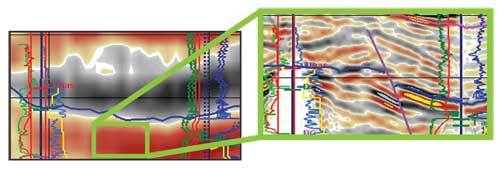

The inadequacy in reservoir information is revealed by reviewing the resolution and coverage of presently available reservoir life-cycle information sources. Fig. 1 provides an overview of the reservoir information ranges covered by the various available technologies. A quick review shows that most of the information is available at a scale suitable for reservoir identification and its bulk characteristics.

|

| Fig. 1. Available technologies provide a range of reservoir information covered at a scale suitable for the reservoir and bulk characteristics identification. |

|

While conventional 3D processes generate a workable aerial view of the reservoir, the technology provides little information about a reservoir’s vertical heterogeneity. In addition, while such conventional processes as well logging, core sampling, and production data analysis do generate information about vertical heterogeneities, they are limited to within a few inches of the well. New, “deep” investigative resistivity and sonic log tools add only a few feet more to the area measured around a well.

What is missing is real information concerning the vertical distribution of heterogeneities between wells. Statistical methods do not provide the hard data necessary to power reservoir understanding and effective management strategies.

CROSSWELL IMAGING

Crosswell imaging provides significant data to help fill the vertical information gap between wells, Fig. 1 green zone. Offering a resolution many times greater than any surface method, this technique provides a detailed look at vertical heterogeneities between wells.

The typical surface seismic view, Fig. 2, provides limited information about the reservoir’s presence, perhaps its thickness and a few bulk properties. The detailed “inside-the-reservoir” view indicates a multi-layer, faulted reservoir. The resolution difference in the two seismic methods is shown by the comparative views.

|

| Fig. 2. The typical 3D surface seismic view (left) provides limited reservoir information, while crosswell imaging (right) reveals a faulted, multi-layered reservoir. |

|

Crosswell imaging employs a seismic source and receivers, both placed in wells at the reservoir level. To image reservoir intervals as thin as 0.5 m to 1 m, the system passes specially-engineered sound waves through the area of interest, from source to receiver, Fig. 3. The change in the sound waves, as they pass through the interwell section, provides both horizontal and vertical information.

|

| Fig. 3. Crosswell imaging uses a seismic source and receivers placed in wells at the reservoir level. |

|

This technique is designed to provide a detailed reservoir view for up to a kilometer between wells. In addition, multiple surveys can provide reservoir continuity and connectivity data across a field. This detailed data is readily integrated into an existing geologic and reservoir model, resulting in a highly effective and comprehensive tool for long-term reservoir management.

Understanding the between-well data is critical to locate left-behind oil. This inter-well information also identifies the production mechanisms within the reservoir and can reveal opportunities for optimizing production.

INTEGRATING TECHNOLOGY

No single technology is a panacea for optimum reservoir management. Rather, global integration of all information sources will be the key to a future revolution in reservoir life-cycle management. Effective reservoir management will be driven by more and better data throughout the reservoir’s life. In fact, operating companies have aligned themselves into cross-functional teams to better manage diverse information.

In this new paradigm, reservoir monitoring is also providing a more continuous flow of information about the reservoir’s condition, becoming the driver for proactive remedial reservoir action. Armed with current data and an in-depth understanding, an asset team is now able to anticipate a reservoir problem before it reaches the well. Many common problems, such as water encroachment and gas leakage, can be proactively addressed before they become critical.

RESERVOIR LIFE CYCLE

The key to improved reservoir management and a higher recovery rate is more and better data about the reservoir, its structure and properties. To effectively acquire quality data, priority and budget must be given to information-generating activities at all stages of a reservoir’s life cycle: exploration, discovery, delineation, production, secondary recovery, tertiary recovery and abandonment.

Many oil companies are faced with mature fields in need of revitalization. In the past, revitalization was strictly focused on well processes: workover, recompletion and other remedial action. Today, deep-investigative crosswell methods can drive reservoir revitalization.

Even though information is indispensable in life-cycle reservoir management, it is not without its cost. The extra time spent to test and analyze increases the price of drilling. In addition, there are risks to the well. These factors always lead to some educated compromise. However, a value proposition that can save a waterflood pilot, avoid a failed deep horizontal well or prevent premature water encroachment justifies the investment.

OPTIMIZED FIELD DEVELOPMENT

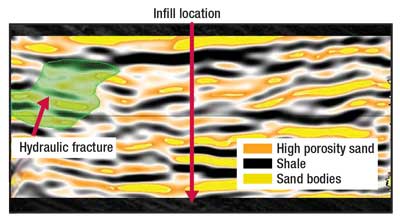

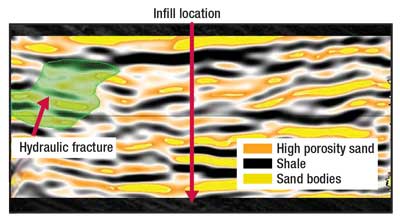

A May 2005 filing with the Wyoming Oil and Gas Commission by Ultra Petroleum demonstrates the value of integrated information for strategic development decisions about a tight gas reservoir. Ultra integrated information from crosswell imaging, 3D surface seismic, cores, logs, production data and microseismic operations to determine that it was feasible to use tighter infill spacing in its Jonah field in Utah in the western US.

Crosswell imaging provided the unique high resolution information that allowed the company’s asset team to directly image thin sand channels in the reservoir, Fig. 4. From this, Ultra determined that the reservoir’s average sand channel size would allow 10-acre well spacing. The imaging also confirmed that hydraulic fracture dimensions, determined from microseismic monitoring, were conformable and constrained by the sand channel geology. Ultra’s information-based decisions eventually resulted in reported incremental recoverable reserves of 14.9 Tcf.

|

| Fig. 4. Crosswell imaging provided high-resolution data to directly image thin sand channels in Ultra Petroleum’s reservoir. |

|

SECONDARY RECOVERY

While secondary recovery through waterflooding often yields half of the total recovery in a field, this process has been traditionally implemented without detailed reservoir knowledge. This is an important point, since the potential for reservoir damage can result from an inadequately planned and poorly executed waterflood program.

Despite this, waterflood pilots are often little more than injectivity tests. The success or failure of the pilot is judged simply by what is recovered at the producer. Waterflooding is inherently a “between-well” operation, which can be thought of as crosswell injection.

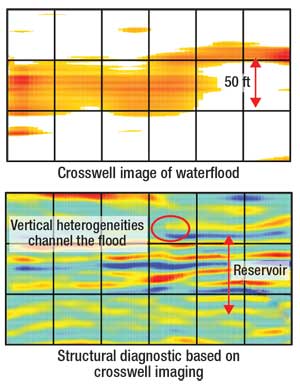

An in-depth understanding of connectivity and continuity are crucial to understand the sweep in secondary recovery. Inside-the-reservoir images are essential for better reservoir understanding, flood planning and monitoring.

A crosswell image can provide a clear geologic picture between wells and monitor both flood fronts and pressure between wells over the project’s life. And, while pressure monitoring and chemical tracers are good indicators of what has reached a producer well, neither effectively describes the vertical characteristics between wells or determines swept and unswept intervals. By running a baseline pattern, new information can assist in planning injector and producer well locations and selecting depths for injection and production. Once water injection is initiated, repeat surveys can establish the front between wells, thief zones and vertical channels that may impact sweep.

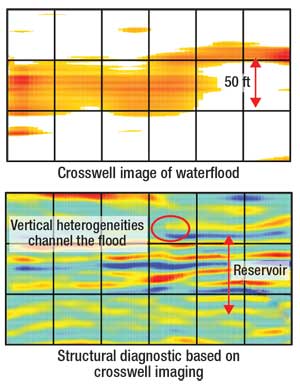

A monitoring example from a heterogeneous reservoir shows that a uniform sweep assumption is often not accurate, Fig. 5. In this case, the sweep was into a zone not completed in the production well. The lack of communication injector-producer masked an opportunity to produce new oil and optimize waterflood pilot success.

|

| Fig. 5. This waterflood monitoring example shows that a uniform sweep assumption is often inaccurate; this sweep was into a zone not completed in the production well. |

|

Monitoring provides the information necessary for quick and effective remedial action within the secondary recovery process. Armed with in-depth interwell information, the operator can shut-off injection into thief zones, reorienting injection patterns to honor the observed sweep and recomplete wells to match the oil channels.

CONCLUSION

With demand for oil and gas showing no signs of slowing, and the cost of drilling escalating, it is imperative to maximize economic recovery from reservoirs. Higher commodity prices, lack of investment opportunity in new exploration, constraints on margins in many international concessions, and declines in the major fields around the world are all driving the focus to existing reservoirs and optimized recovery through reservoir life-cycle management.

New information technologies such as crosswell imaging are filling the critical information gap within the reservoir between the wells and driving a new life-cycle approach to reservoir production and management. Operators are now equipped to address the new frontier inside the reservoir and realize increasingly better recovery rates.

|

THE AUTHOR

|

|

Raul Ortiz earned a BS degree in petroleum engineering from the Polytechnic Institute of Ecuador and an MS degree in petroleum engineering from the Colorado School of Mines. Prior to starting his own company, he worked for Texaco in a range of executive positions in petroleum engineering, operations, new business development, and technology management. Ortiz is president of Raul Ortiz and Associates, an oil and gas reservoir consulting firm.

|

|

| |

| |

|